Application of Auto Bender Machine in Automobile Manufacturing

2025-06-25

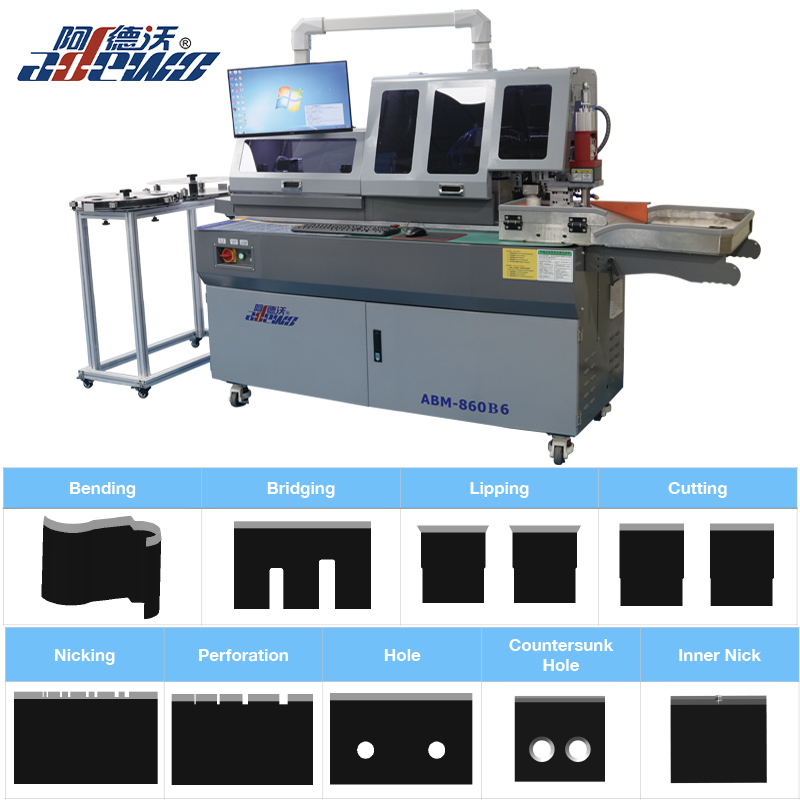

Auto bender machines, also known as automated bending machines, have become integral to the modern automobile manufacturing process. These machines are designed to bend or form metal parts into specific shapes and angles, an essential function in producing various vehicle components. The use of automated technology in this process significantly enhances precision, speed, and cost-efficiency, all critical factors in the highly competitive automotive industry. This essay explores the role of auto bender machines in automobile manufacturing, discussing their applications, benefits, and impact on production.

1. Manufacturing of Structural Components

One of the primary applications of auto bender machines in automobile manufacturing is the production of structural components. These include parts such as chassis frames, cross-members, and support beams, which are critical for the safety and integrity of the vehicle. These components require precise bending to ensure they meet strict design specifications and safety standards.

Auto bender machines can handle different materials, including high-strength steel, aluminum, and even composite materials, making them versatile in producing a variety of parts. The machines employ CNC (Computer Numerical Control) systems that allow for high-precision bending, ensuring uniformity across large production runs. This is especially important for maintaining consistency in the structural integrity of a vehicle, which is paramount for both performance and safety.

2. Exhaust System Manufacturing

Another key application of auto bender machines is in the production of exhaust systems. Exhaust pipes, catalytic converters, and mufflers are all components that require precise bending to fit correctly within a vehicle’s design. The bending process must be carried out with high precision to ensure the parts align properly with other systems, such as the engine and undercarriage.

Automated bender machines are equipped with features such as programmable settings, allowing manufacturers to create exhaust system components with complex bends and varying diameters. These machines are capable of producing components in large quantities, ensuring that the exhaust systems are made with uniform quality, contributing to the overall efficiency of the manufacturing process.

3. Suspension and Steering Components

Auto bender machines are also utilized in the production of suspension and steering system components, such as control arms, steering linkages, and shock absorber brackets. These components need to be bent with extreme precision to ensure proper functioning within the vehicle’s suspension system.

The machines help achieve the tight tolerances required for these components, which directly affect the handling, comfort, and safety of the vehicle. In addition to bending, auto bender machines can also perform other operations, such as cutting and notching, in one integrated process, improving overall manufacturing efficiency.

4. Interior Components and Accessories

While auto bender machines are primarily associated with structural and mechanical components, they also play a significant role in producing interior parts such as seat frames, dashboard supports, and trim pieces. These components often require bending and shaping of lighter gauge metals or other materials.

The precision of auto bender machines ensures that these parts fit seamlessly within the interior design of the vehicle. Furthermore, the ability to process materials with complex shapes and intricate curves allows automobile manufacturers to offer a wider variety of interior designs, enhancing the customization options for consumers.

5. Electrical System Components

In modern vehicles, the integration of electrical systems such as wiring harnesses, brackets, and connectors is essential. Auto bender machines are used to create metal parts that support the routing of electrical wires and ensure proper insulation and protection for the electrical components. The bending process ensures that these parts are produced with the necessary strength to hold electrical components securely while being lightweight to optimize space and reduce vehicle weight.

6. Cost-Effectiveness and Time Efficiency

The application of auto bender machines in automobile manufacturing offers significant cost-saving opportunities. Automated machines operate at high speeds and with greater accuracy compared to manual processes. As a result, manufacturers can produce more parts in less time, reducing labor costs and increasing production capacity. The precision of these machines also reduces material waste, as parts are bent according to exact specifications, minimizing the need for rework or scrap.

Moreover, the automation of the bending process ensures that components are produced with minimal human intervention, resulting in a more streamlined and less error-prone production line. This not only speeds up the manufacturing process but also enhances the overall quality and consistency of the parts produced.

7. Customization and Flexibility

Auto bender machines are highly flexible, allowing manufacturers to produce a wide range of parts with varying dimensions and geometries. This is particularly important in the automotive industry, where different models of vehicles may require different component specifications. The ability to quickly adjust the settings of the machine allows for a high degree of customization, which is essential in producing vehicles with diverse features and configurations.

For instance, when a car model requires specific bends or angles for a certain component, the auto bender machine can be reprogrammed to handle these modifications. This flexibility ensures that manufacturers can meet the unique requirements of various vehicle models while maintaining efficiency and quality.

8. Advancements in Technology

The integration of advanced technologies such as artificial intelligence (AI) and machine learning into auto bender machines has further revolutionized the manufacturing process. These technologies enable the machines to learn and adapt to various bending tasks, improving their performance over time. AI-powered systems can also detect potential issues in real-time, allowing for quick adjustments and ensuring that the final product meets stringent quality standards.

Furthermore, the use of 3D simulation software allows engineers to design complex bending patterns and test them virtually before applying them to the machine. This reduces the need for physical prototypes and accelerates the design and production cycles.

Conclusion

The application of auto bender machines in automobile manufacturing has transformed the industry by improving the efficiency, precision, and cost-effectiveness of producing critical vehicle components. From structural and mechanical parts to electrical and interior components, these machines play a vital role in ensuring that automobiles are built to high standards of safety, performance, and aesthetics. With continued advancements in technology, the role of auto bender machines is likely to expand further, contributing to even greater innovation in the automotive sector.