Are Mobile Block Making Machines Suitable for On-Site Production

2025-09-30

For contractors and builders, the logistics of transporting concrete blocks to remote or constrained sites can be a major headache. This leads many to ask a critical question: are mobile block making machines a practical solution for on-site production? The resounding answer is yes, and they are revolutionizing project efficiency.

Unlike stationary plants, a mobile Block Making Machine is a compact, self-contained unit mounted on a trailer chassis. It is designed to be towed directly to your project location, eliminating the need for costly and time-consuming block transportation. This is the core of its value proposition for on-site work.

What Are the Core Advantages of a Mobile Block Making Machine

The benefits extend far beyond simple mobility. Here are the key advantages

-

Drastic Cost Reduction Slash transportation fees and material loss from transit damage.

-

Unmatched Flexibility Produce blocks exactly where and when they are needed, responding to project demands in real-time.

-

Faster Project Timelines Begin blockwork immediately upon machine setup, without waiting for deliveries.

-

Reduced Carbon Footprint Minimize the environmental impact of your project by removing multiple truck deliveries.

How Does the QGM Mobile Model Stack Up on Specifications

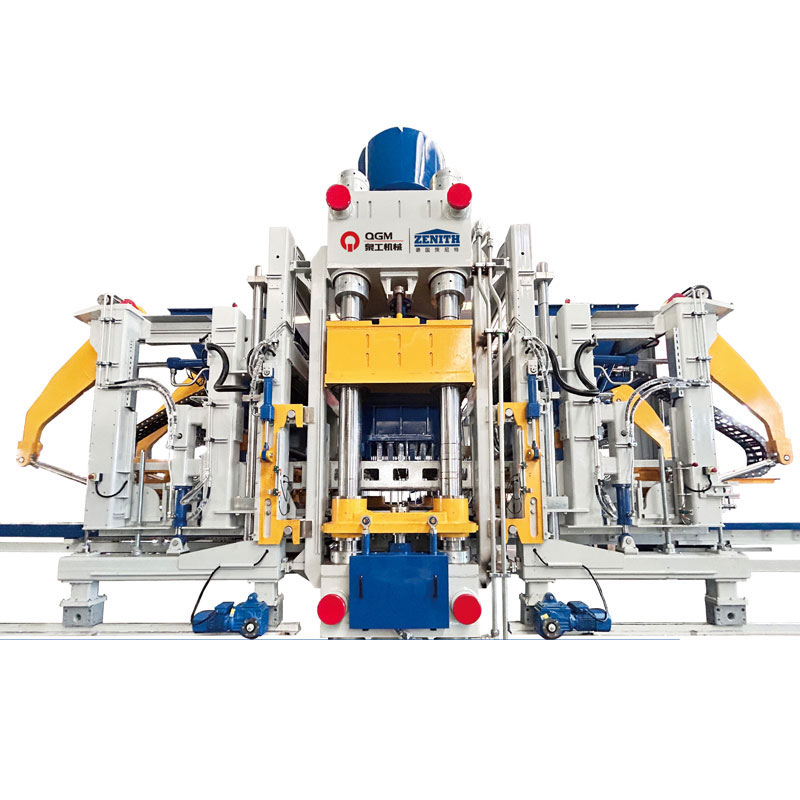

Let's look at the technical details of a leading model, the QGM M-series, to understand its on-site capability.

| Feature | Specification |

|---|---|

| Production Capacity | Up to 1,500 standard blocks per 8-hour shift |

| Power Source | Integrated diesel generator or external power connection |

| Setup Time | Less than 30 minutes |

| Key Component | High-frequency vibration system for superior block density |

This robust design ensures that you receive a high-quality product without compromise. The QGM mobile Block Making Machine is engineered for durability in tough site conditions, delivering consistent performance where it matters most.

Your Mobile Block Making Machine Questions Answered

FAQ 1 What kind of raw materials can a mobile block machine use

It can use standard cement, aggregates, and sand. The mix design might need slight adjustments from your typical plant mix to optimize for the machine's specific compaction system, and QGM provides full technical support to achieve the perfect mix.

FAQ 2 How does the finished block quality compare to stationary plant blocks

The quality is identical, often superior to low-grade plant blocks. Machines like the QGM model use high-pressure vibration to create densely compacted, strong blocks that meet or exceed standard construction requirements.

FAQ 3 What is the typical payback period for this investment

For projects with significant block volume and long transport distances, the payback period can be remarkably short—often under 12 months. The savings on logistics directly contribute to your project's bottom line.

If you are ready to cut costs, increase flexibility, and take control of your supply chain, it's time to explore a mobile solution. Contact us today to discuss your project requirements and see how a QGM mobile Block Making Machine can make your next project more profitable.