Are You Getting The Most From Your Blister Packaging Machine Investment

2025-09-28

As a packaging professional with two decades of experience, I often see companies struggling with underperforming assets. A Blister Sheet Machine is a significant investment, and many operations are not realizing its full potential. Are you facing high downtime, excessive waste, or inability to adapt to new packaging formats? These are common signs that your current setup is costing you more than just the initial price.

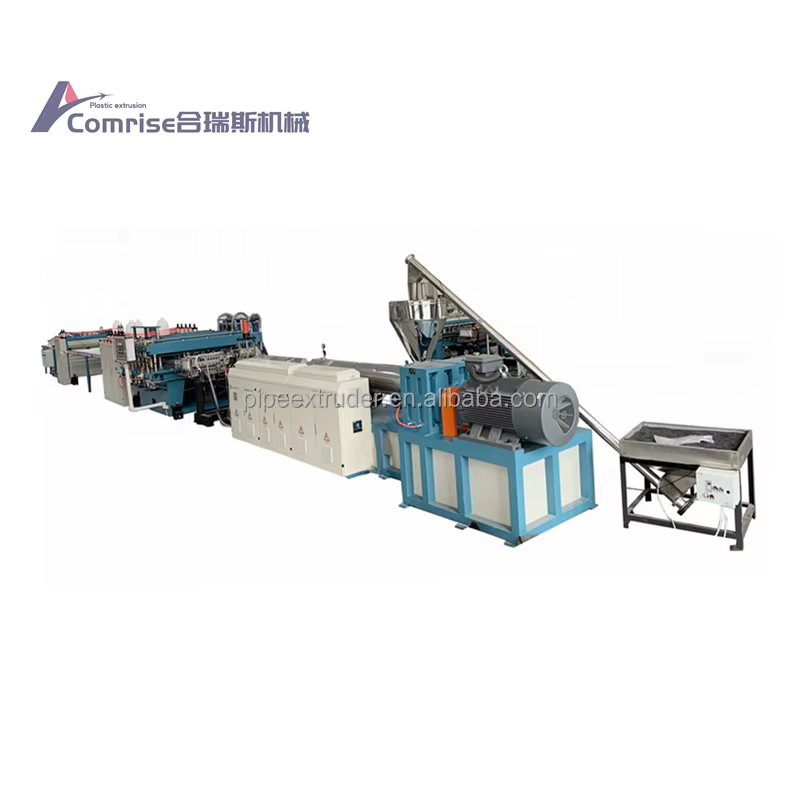

Maximizing your return on investment requires a machine built for efficiency, flexibility, and reliability. At Comrise, we engineer our Blister Sheet Machine solutions with this precise goal. The key is in the details.

Essential Features of a High-ROI Blister Sheet Machine

-

Quick Changeover Systems: Minimize downtime with tool-less adjustments and digital recipe storage.

-

Precision Control: Zoned heating and programmable sealing ensure consistent quality and reduce material waste.

-

Modular Design: Adapt your machine to future needs with add-ons like integrated vision inspection.

The following table highlights the performance gap between a standard machine and the Comrise AgilePack series:

| Performance Metric | Standard Machine | Comrise AgilePack |

|---|---|---|

| Average Changeover Time | 2-3 Hours | Under 30 Minutes |

| Material Waste per Changeover | High | Minimal |

| Operational Skill Requirement | Specialist Technician | Standard Line Operator |

Your Blister Sheet Machine FAQ

What is the biggest factor affecting my machine's ROI

The single biggest factor is often unplanned downtime. A Blister Sheet Machine that requires frequent adjustments or lengthy changeovers directly eats into your profitability through lost production hours and wasted materials.

Can older blister packaging machinery be upgraded

Yes, in many cases. Comrise offers retrofit solutions for various machine types, including upgraded control systems and quick-change parts, which can significantly enhance performance and extend the asset's life without a full replacement.

How does the Comrise Blister Sheet Machine ensure consistent quality

Our machines feature advanced process monitoring and closed-loop control systems for critical parameters like temperature and pressure. This consistent precision ensures every blister pack meets quality standards, reducing reject rates and protecting your brand reputation.

Stop letting an underperforming Blister Sheet Machine drain your resources. Contact us at Comrise today for a free, no-obligation productivity assessment. Let our experts show you how to unlock the full value of your packaging line investment.