How Can a Board Production Line Transform My Manufacturing Process?

2025-09-12

In today's competitive manufacturing industry, efficiency and precision are more critical than ever. As a manufacturer, I constantly seek ways to improve production quality while reducing downtime and operational costs. That is why I have been exploring the potential of a Board Production Line. This advanced system integrates cutting-edge automation with precise control to produce high-quality boards consistently. By adopting a Board Production Line, I have noticed significant improvements in production speed, product uniformity, and overall operational efficiency.

What is the Role of a Board Production Line?

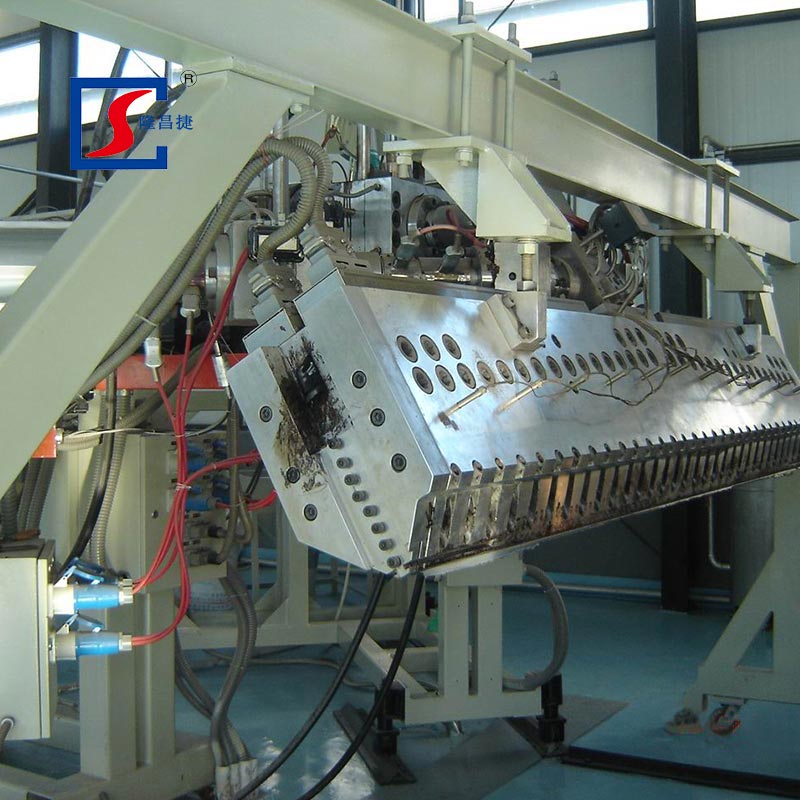

The primary role of a Board Production Line is to automate the process of producing various types of boards, including particle boards, MDF, plywood, and laminated boards. It combines multiple operations—such as material feeding, pressing, cutting, sanding, and finishing—into a streamlined workflow.

Key Functions of a Board Production Line:

| Function | Description |

|---|---|

| Material Feeding | Automatic loading and distribution of raw materials |

| Pressing | Ensures uniform density and thickness of the board |

| Cutting & Shaping | Precision cutting according to size and design requirements |

| Sanding & Finishing | Smooth surface preparation and enhanced product quality |

| Quality Inspection | Detects defects and ensures consistency |

I asked myself, "How exactly does this system improve efficiency?" The answer became clear after integrating it into our workflow. With automated operations and reduced manual intervention, the production speed increased significantly, while material wastage dropped, leading to cost savings.

What Are the Benefits and Effects of Using a Board Production Line?

Using a Board Production Line offers measurable benefits that impact production, workforce, and overall business growth:

-

Higher Productivity: Continuous production cycles and minimal downtime.

-

Consistent Quality: Precision control ensures uniform board thickness and surface quality.

-

Labor Savings: Automation reduces reliance on manual labor for repetitive tasks.

-

Resource Optimization: Efficient use of raw materials lowers waste and production costs.

-

Customization Capabilities: Adaptable settings for producing different board types and sizes.

I often wonder, "Will it really make a difference in product quality?" From my experience, the answer is an unequivocal yes. The boards produced show remarkable consistency in density, thickness, and finish, enhancing customer satisfaction and reducing rejection rates.

Why is a Board Production Line Important?

The importance of a Board Production Line extends beyond mere production. It acts as a strategic investment in modernizing manufacturing and securing a competitive advantage. The system not only reduces operational costs but also boosts production reliability and product standardization.

Critical Importance Factors:

-

Operational Stability: Continuous, automated production reduces human errors.

-

Market Competitiveness: High-quality boards allow for better pricing and customer trust.

-

Scalability: Easy expansion for future production increases without significant infrastructure changes.

Finally, I asked myself, "Should I consider upgrading to the latest models?" The answer is yes, because ongoing technological improvements in Board Production Line systems offer better energy efficiency, faster production cycles, and enhanced safety features.

In conclusion, a Board Production Line is not just a piece of equipment; it is a comprehensive solution for modern board manufacturing. By integrating automated processes, quality control, and operational efficiency, it offers tangible benefits to any manufacturing enterprise aiming for growth and excellence. For professional guidance, installation support, and product inquiries, I highly recommend contacting Qingdao Longchangjie Machinery Co., Ltd.