How Can a Brick Machine Curing Room Improve My Block Quality and Output?

2025-07-30

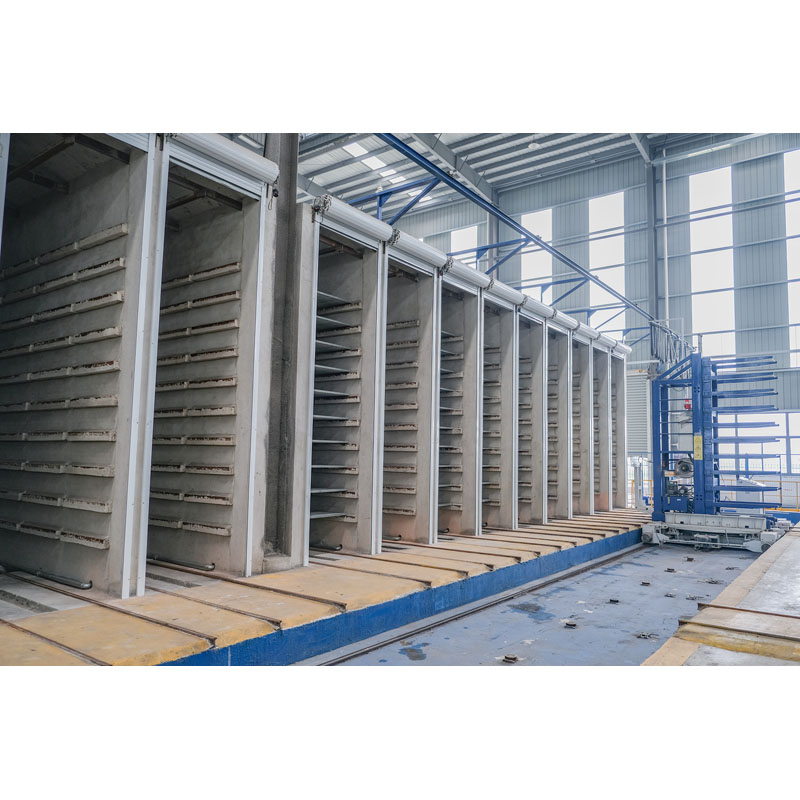

Back when I started in this industry, I thought making strong bricks was all about the right mix and a powerful block machine. Turns out, I was only half right. No matter how well you shape a block, if the curing isn’t done properly, you’ll still end up with weak, inconsistent products. That’s when I learned the real value of a proper brick machine curing room.

Once we brought one into our line, everything started to change—better strength, fewer defects, and faster turnaround. I’m sharing this because I wish someone had told me sooner.

Why Does Curing Matter So Much in Brick Production?

Think about it: cement doesn’t “dry,” it cures. That process depends heavily on moisture and temperature. If the environment is too dry or too cold, bricks don’t cure evenly. We saw cracks, warping, and strength loss in far too many units before we had a brick machine curing room.

After installing the room, everything became stable. The blocks stayed in a controlled setting, with steady humidity and heat, which allowed the cement to bond properly. The result? Stronger, longer-lasting bricks that customers could trust.

Does a Brick Machine Curing Room Save Time and Cost?

Absolutely. Before the brick machine curing room, we were waiting two, even three days for blocks to reach the strength we needed to move or stack them. Now, we can cut that time nearly in half. That lets us move more product through the line each day, boosting productivity without extra labor or equipment.

Also, fewer broken bricks mean less waste. We used to throw out hundreds of pieces a month due to poor curing. Now that number is nearly zero. That’s money saved—plain and simple.

Can It Be Adapted to Different Factory Sizes?

That was one of my biggest concerns. We didn’t have a huge site, and I worried we’d need to restructure the whole plant. But with help from QGM, we found a solution that fit. Their brick machine curing room design is flexible and scalable, so it matched our production space without heavy modifications.

They offered guidance throughout, and the install went smoother than expected. Now I can’t imagine running the plant without it.

Is the Upgrade Worth It for a Growing Business?

If you’re serious about block quality and production speed, it’s more than worth it. You can have the best mixer, the most advanced press, but if your bricks cure in poor conditions, you’ll keep facing rejections and returns. The brick machine curing room was the missing piece we didn’t know we needed.

Investing in a brick machine curing room changed the way we operate. It brought structure and reliability to a part of the process that we used to leave to chance. If you're still curing bricks in open air or makeshift spaces, consider what a controlled environment can do for your business.

Our products are highly reliable. If you have any needs, please feel free to contact us at any time. We will be online 24/7 to provide you with efficient solutions.