How Can a Manual Cap Threading Machine Revolutionize Your Production Line?

2025-11-27

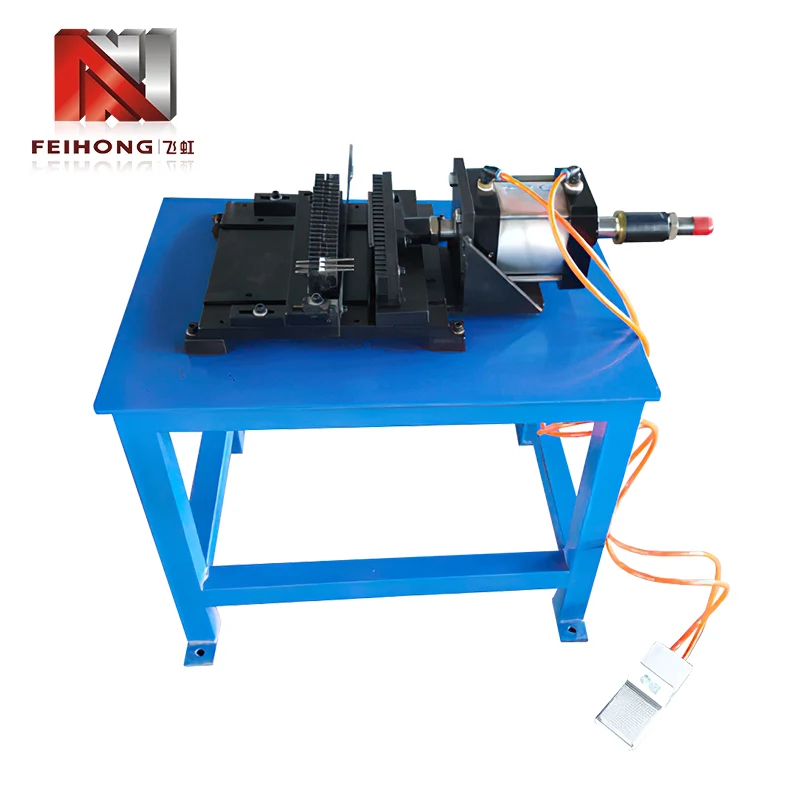

In today's competitive manufacturing landscape, efficiency and precision are paramount. At Zhaoqing Feihong Machinery & Electrical Co., Ltd., we understand the challenges our clients face. That's why we are passionate about our robust and reliable Manual Cap Threading Machine. This machine is a cornerstone for businesses seeking to enhance their cap and bottle finishing processes without the complexity of fully automated systems. I believe that integrating our Manual Cap Threading Machine into your workflow is a game-changer for quality control and small-batch production.

What Does It Do?

The primary role of our Manual Cap Threading Machine is to create precise, consistent internal or external threads on various types of caps and small plastic components. This process is essential for ensuring that caps screw onto bottles and containers securely, preventing leaks and maintaining product integrity. It's a fundamental step in the packaging industry for sectors like food and beverage, pharmaceuticals, and cosmetics.

What Results Can You Expect?

By utilizing our machine, you can achieve a significant uplift in your production quality and operator control. The Manual Cap Threading Machine allows for hands-on threading, which is perfect for prototypes, low-volume orders, or specialized caps where automated systems are not cost-effective. The results speak for themselves:

-

Superior Thread Quality: Produces clean, burr-free threads every time.

-

Enhanced Operator Skill: Empowers your team with a tool that requires and builds valuable technical skill.

-

Reduced Waste: Minimizes material loss due to threading errors.

-

Unmatched Flexibility: Quick changeover between different cap sizes and thread specifications.

In my experience, clients who have integrated our machine report a dramatic decrease in faulty products and a greater sense of autonomy on the shop floor.

Why is it So Important?

The importance of this machine cannot be overstated. It fills a critical niche between hand-tool operations and high-cost automation. For startups and established factories alike, it represents an affordable entry point into professional-grade cap finishing. It ensures that your products meet the highest standards of quality and functionality, which directly impacts customer satisfaction and brand reputation. For our company, providing this reliable solution is at the core of our mission to support growing businesses.

Frequently Asked Questions (FAQ)

Q: Is the Manual Cap Threading Machine difficult to set up and operate?

A: Not at all! Our machine is designed for simplicity. We provide clear instructions, and most operators can become proficient with basic training. Its user-friendly design is one of its biggest strengths.

Q: Can this machine handle different cap materials?

A: Yes, absolutely. Our Manual Cap Threading Machine is versatile and can thread caps made from various plastics and even some softer metals. The key is using the appropriate cutting tool for the material.

Q: What kind of technical support does Zhaoqing Feihong Machinery offer?

A: We stand firmly behind our products. Our team provides comprehensive support, including installation guidance, operational training, and readily available spare parts to ensure your machine operates smoothly for years to come.

Key Specifications at a Glance

| Feature | Specification |

|---|---|

| Operation Type | Manual, Hand-Cranked |

| Typical Application | Internal/External Threading on Caps |

| Material Compatibility | Plastic, ABS, Nylon, PP, etc. |

| Advantages | Cost-Effective, High Precision, Easy to Use |

| Ideal For | Small Batch Production, Prototyping, Repairs |

We are confident that our machine will become an invaluable asset in your workshop. Let us help you elevate your production quality.

Contact us today at Zhaoqing Feihong Machinery & Electrical Co., Ltd. to discuss how our Manual Cap Threading Machine can provide the perfect solution for your needs. Boost your efficiency and quality with our reliable equipment!