How Can a Spraying Robot Transform Your Industrial Operations?

2026-01-09

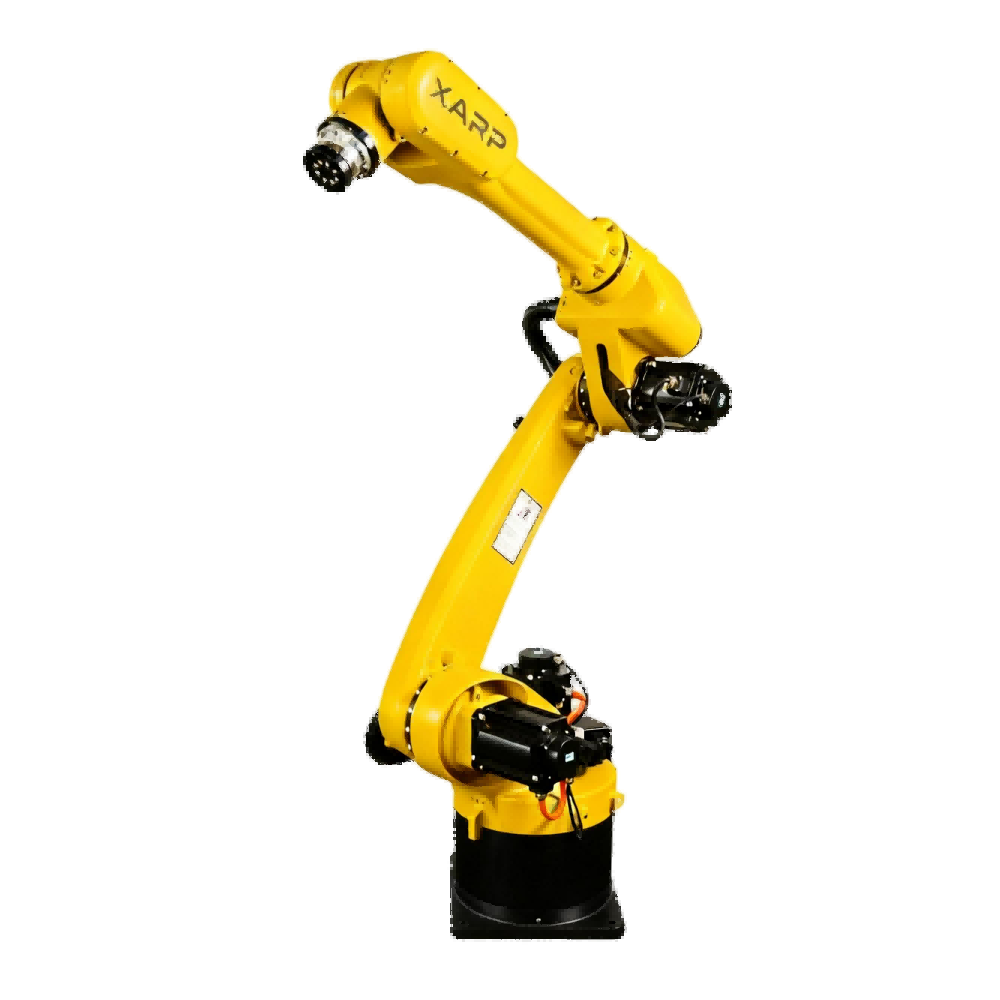

In modern manufacturing and industrial applications, efficiency, precision, and safety are critical. Spraying robots have emerged as a transformative solution for companies seeking high-quality coatings and automated production processes. Wenzhou XARP Industrial Robot Co., Ltd. is at the forefront of developing advanced spraying robot systems designed to optimize workflow, reduce labor costs, and enhance overall product quality.

By automating repetitive spraying tasks, these robots not only improve efficiency but also maintain consistent quality, which is often difficult to achieve manually. From automotive painting to protective coatings on metal structures, spraying robots have become an indispensable tool in industrial settings.

What Are the Key Advantages of Using a Spraying Robot?

Spraying robots offer several notable benefits that make them superior to manual operations:

| Advantage | Description |

|---|---|

| Precision | Ensures uniform coating thickness and coverage |

| Efficiency | Reduces production time by automating repetitive tasks |

| Safety | Minimizes worker exposure to hazardous chemicals |

| Cost-saving | Lowers labor costs and reduces material waste |

| Flexibility | Adapts to different surfaces, shapes, and spray materials |

Why Choose Wenzhou XARP Industrial Robot Co., Ltd. Spraying Robots?

Wenzhou XARP Industrial Robot Co., Ltd. provides state-of-the-art spraying robot solutions tailored to diverse industrial needs. Their systems are engineered with advanced sensors, programmable controllers, and flexible arms, allowing for precise movements and consistent application of coatings.

-

Customizable Programs: Easily adjust spray patterns, speed, and angles.

-

Durability: High-quality components ensure long-term reliability.

-

Integration: Can be seamlessly integrated with existing production lines.

-

Technical Support: Professional guidance from installation to maintenance.

How Do Spraying Robots Compare to Manual Spraying?

| Feature | Manual Spraying | Spraying Robot |

|---|---|---|

| Consistency | Often uneven | Highly consistent |

| Speed | Slower, labor-intensive | Fast and automated |

| Safety | High exposure to chemicals | Minimal human exposure |

| Cost | High over time | Long-term savings |

| Precision | Operator-dependent | Sensor-controlled precision |

Clearly, adopting a spraying robot provides measurable improvements in efficiency, quality, and safety, making it a strategic investment for modern manufacturing operations.

Applications of Spraying Robots

Spraying robots are versatile and suitable for a wide range of industries:

-

Automotive: Car body painting and coating.

-

Metal Fabrication: Protective anti-corrosion coating.

-

Woodworking: Lacquering and finishing.

-

Electronics: Conformal coating of delicate components.

-

Agriculture: Precise application of pesticides or nutrients in greenhouses.

Conclusion

Incorporating a spraying robot from Wenzhou XARP Industrial Robot Co., Ltd. into your production line can significantly enhance efficiency, precision, and workplace safety. These advanced robotic systems are not only cost-effective but also flexible and reliable, meeting the evolving demands of modern industries.

Ready to take your production to the next level? Contact us today at Wenzhou XARP Industrial Robot Co., Ltd. and discover how our spraying robots can revolutionize your operations.