How Do Cryogenic Control Valves Ensure Safe?

2025-09-28

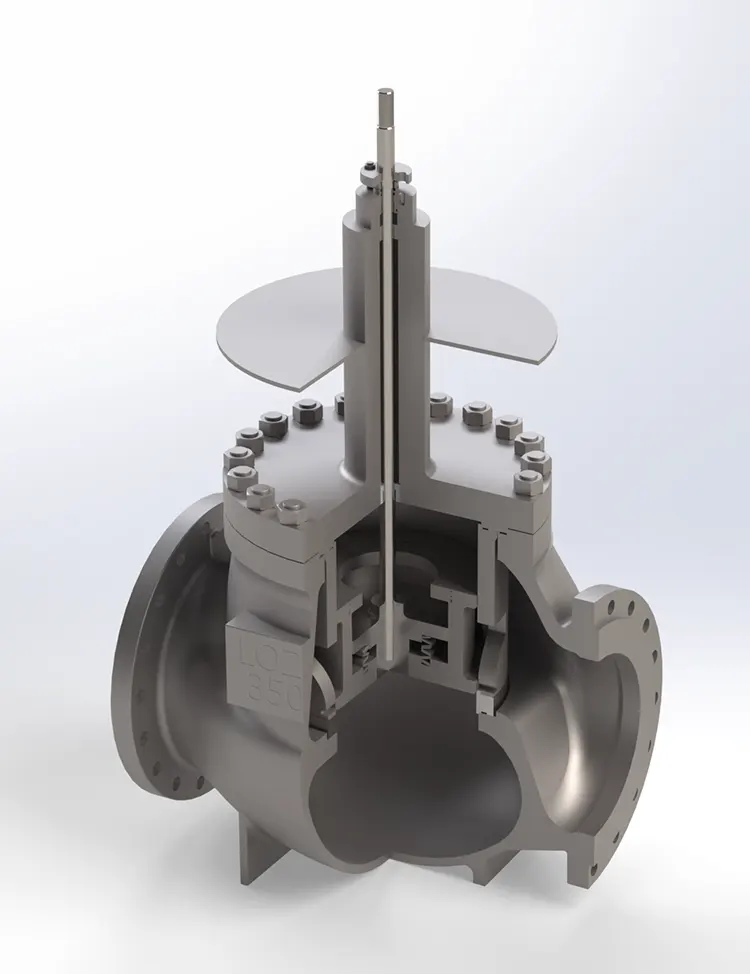

Cryogenic systems are among the most demanding industrial applications because they operate at extremely low temperatures, often below -150°C. In industries such as liquefied natural gas (LNG), aerospace, chemical processing, and medical gas supply, maintaining the stability and safety of cryogenic fluids is essential. At the center of these systems lies the Cryogenic Control Valve, a highly specialized device designed to regulate the flow, pressure, and temperature of cryogenic liquids and gases.

A Cryogenic Control Valve must perform tasks that ordinary valves cannot. Standard valves face challenges like material brittleness, leakage due to contraction, and frosting, which compromise reliability. Cryogenic valves are engineered with materials and designs that maintain resilience and sealing strength under extreme cold. They ensure precise control in applications like LNG storage tanks, cryogenic air separation plants, and rocket propellant systems.

The reliability of a cryogenic valve is not just a matter of performance—it is a matter of safety. Improper control in cryogenic systems can result in catastrophic failure, environmental hazards, or loss of valuable gases. For this reason, companies invest in advanced cryogenic valve solutions that guarantee efficiency, leak-proof operation, and long service life.

How Do Cryogenic Control Valves Work in Practice?

To understand the function of cryogenic valves, it is important to look at both the design elements and the operating mechanisms. Unlike conventional valves, cryogenic valves are designed with a longer bonnet, which extends the stem away from the cryogenic medium. This prevents frost accumulation and keeps the gland packing at a temperature where it remains flexible.

Key working principles include:

-

Thermal isolation: The extended bonnet minimizes heat transfer, ensuring valve components do not freeze or crack.

-

Leak prevention: High-performance sealing systems maintain tight shutoff even under severe contraction.

-

Flow accuracy: Specialized trim designs allow precise modulation, which is vital when handling volatile or expensive cryogenic fluids.

-

Durability under cycling: Cryogenic valves withstand repeated opening and closing cycles without losing integrity, even at -196°C for liquid nitrogen or LNG.

To highlight technical features clearly, here is a breakdown of product parameters in a professional comparison table:

| Parameter | Specification Range / Feature |

|---|---|

| Operating Temperature Range | -196°C to +60°C |

| Pressure Ratings | PN16 to PN100 / ANSI Class 150–600 |

| Body Materials | Stainless Steel (CF8M, CF3M), Bronze, Cryogenic-Grade Alloys |

| Trim Design | Globe, Angle, Ball, Butterfly options |

| Bonnet Type | Extended bonnet with low-heat transfer design |

| Seat Type | Soft seat or metal-to-metal seat for tight shutoff |

| Actuation Options | Manual, Pneumatic, Electric |

| Sizes Available | DN15 to DN600 (½” to 24”) |

| Standards Compliance | BS 6364, API 598, ISO 28921, MSS SP-134 |

| Leakage Class | Class VI (bubble-tight shutoff) |

| Application Areas | LNG plants, aerospace fueling, cryogenic storage, medical gas systems |

These parameters demonstrate why cryogenic valves are chosen over conventional designs—they are engineered to sustain performance even when subject to the extreme stresses of cryogenic service.

Industrial Applications and Benefits of Cryogenic Control Valves

Cryogenic valves are indispensable in multiple industries. Each application has unique demands, yet the fundamental requirement is the same: safe, leak-free, and efficient control at ultra-low temperatures.

Key Industry Applications

-

Liquefied Natural Gas (LNG) – Control valves regulate LNG flow in storage, transport, and regasification terminals, where precision determines both safety and efficiency.

-

Aerospace and Rocket Propulsion – Cryogenic propellants like liquid hydrogen and oxygen demand valves that can cycle rapidly while maintaining structural stability.

-

Medical and Laboratory Gases – Hospitals and research labs rely on cryogenic valves to regulate liquid oxygen, nitrogen, and helium for breathing support, freezing, and testing.

-

Air Separation Units (ASU) – Industrial gas plants use cryogenic valves in oxygen, nitrogen, and argon production.

-

Chemical Processing – Cryogenic conditions are required in various reactions and separations where conventional valves cannot function reliably.

Benefits of High-Quality Cryogenic Control Valves

-

Safety Assurance – Preventing leakage and ensuring tight shutoff avoids oxygen enrichment hazards and costly fluid losses.

-

Efficiency and Cost Savings – Optimized flow control reduces waste and maximizes system performance.

-

Long Service Life – Designed to resist embrittlement and wear, reducing downtime and replacement costs.

-

Compliance with Global Standards – Ensures valves meet stringent industry safety codes.

-

Operational Flexibility – Multiple actuation and trim options allow integration into automated or manual systems.

The effectiveness of cryogenic valves depends heavily on choosing the right specification for each application. For example, an LNG terminal may prioritize large-size, high-flow ball valves, while a laboratory may require smaller globe valves with precise throttling capabilities.

How to Select the Right Cryogenic Control Valve and Common Questions Answered

Factors to Consider When Choosing a Cryogenic Valve

-

Temperature Range – Ensure the valve material can withstand the lowest service temperature.

-

Pressure Requirements – Match valve pressure class with system conditions.

-

Fluid Type – Different cryogenic fluids may require specialized sealing materials.

-

Flow Characteristics – Choose globe valves for precise control, ball valves for high capacity, and butterfly valves for compact systems.

-

Actuation Needs – Decide between manual, pneumatic, or electric actuation based on automation requirements.

-

Standards Compliance – Always select valves certified under relevant standards such as BS 6364.

Making the wrong choice can result in inefficiency, leakage, or even system shutdown. For this reason, engineers often work with trusted manufacturers to configure solutions tailored to their unique system demands.

Frequently Asked Questions (FAQ)

Q1: How do cryogenic control valves prevent leakage at extremely low temperatures?

A1: Cryogenic control valves use extended bonnets to isolate gland packing from cryogenic temperatures, preventing it from hardening or cracking. They also feature high-performance seat designs—such as soft or metal-to-metal seals—that remain tight even during material contraction, ensuring bubble-tight shutoff.

Q2: How can I ensure the longevity of a cryogenic control valve in continuous operation?

A2: Proper material selection, regular inspection, and compliance with industry standards are key. Using stainless steel or cryogenic-grade alloys helps resist embrittlement. Routine maintenance ensures seals remain intact, while choosing valves with proven compliance (BS 6364, API standards) guarantees durability under repetitive thermal cycles.

Cryogenic systems operate at the edge of engineering challenges, and reliable performance depends heavily on selecting the right control valve. From LNG terminals to aerospace fueling, these valves provide the safety, accuracy, and efficiency necessary for critical low-temperature operations. High-quality cryogenic control valves are not just components; they are strategic assets that safeguard operations and ensure compliance with international safety standards.

With decades of expertise in industrial valve manufacturing, Lozose delivers cryogenic solutions trusted across global industries. Our valves are engineered to perform under the harshest cryogenic conditions, ensuring both safety and efficiency. To learn more about our cryogenic control valve range or to discuss customized solutions for your specific application, contact us today and speak with our engineering team.