How Do Mobile Crushing Plants Transform Modern Construction and Mining?

2025-09-29

In the fast-changing world of construction, quarrying, and mining, the demand for efficient, cost-effective, and environmentally conscious equipment has never been greater. Mobile crushing plants have become a vital solution, offering unmatched flexibility and power. Unlike traditional stationary crushing systems, mobile units can be transported directly to job sites, reducing both logistical costs and project timelines.

But how exactly do mobile crushing plants work, and why have they become indispensable for modern industries?

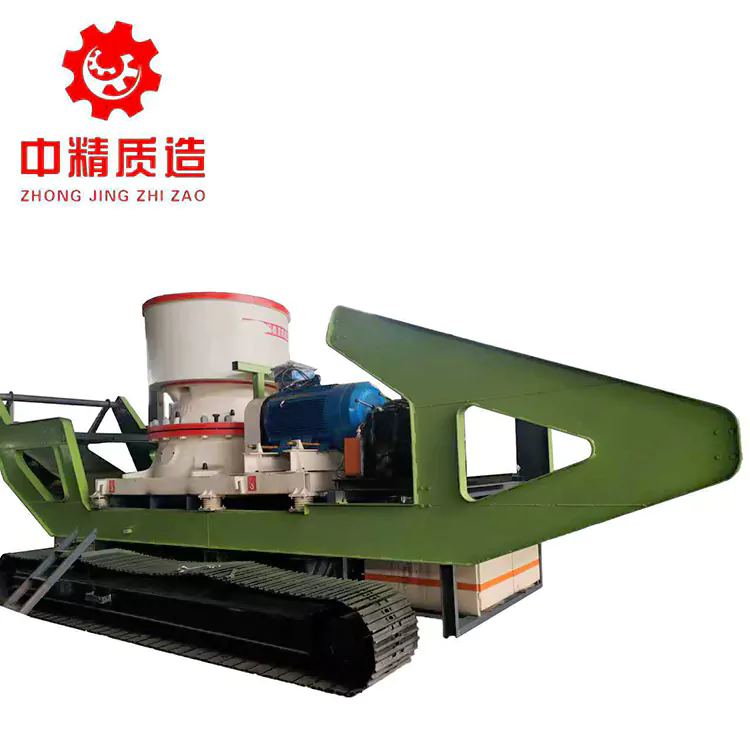

Mobile crushing plants are essentially self-contained crushing units mounted on wheels or tracks. They are designed to move freely between sites and can process a wide range of raw materials—stone, gravel, concrete, asphalt, ore, and demolition waste—into high-quality aggregates. Equipped with powerful crushers, screens, conveyors, and integrated automation systems, these machines provide a complete, on-site solution for crushing and screening.

Key benefits of mobile crushing plants include:

-

Flexibility – Ability to work in remote or urban areas with minimal setup time.

-

Cost Savings – Reduction in transportation of raw materials and aggregates.

-

Efficiency – High production capacity with optimized energy consumption.

-

Sustainability – Support for recycling and eco-friendly aggregate production.

-

Scalability – Wide range of models to fit small contractors and large-scale industrial operations.

These advantages explain why industries worldwide—from highway construction to mining exploration—are steadily shifting from stationary plants to mobile solutions.

What Defines a Professional Mobile Crushing Plant

While the concept of a mobile crusher is simple, the performance of these machines depends on carefully engineered specifications. A professional-grade mobile crushing plant must balance power, mobility, and adaptability. Below is a structured overview of typical parameters that define quality:

| Parameter | Specification Range | Description |

|---|---|---|

| Crushing Capacity | 50 – 600 tons per hour | Determines how much raw material can be processed efficiently. |

| Crusher Type | Jaw, Impact, Cone, or Hybrid | Choice depends on material hardness and project requirements. |

| Feeding Size | Up to 800 mm | Larger feed size allows processing of raw and oversized materials. |

| Output Size | 0–5 mm, 5–20 mm, 20–40 mm (adjustable) | Flexibility to produce multiple aggregate sizes for different applications. |

| Mobility | Wheeled or Tracked | Tracked units offer better maneuverability in rough terrain. |

| Power Source | Diesel engine, Electric, or Hybrid | Hybrid models reduce fuel consumption and CO2 emissions. |

| Screening System | Single-deck, double-deck, or triple-deck screens | Separates crushed materials into uniform product categories. |

| Conveyor System | Folding, multi-layer conveyors | Ensures smooth material transfer and stockpiling. |

| Automation & Control | PLC touch-screen system | Enhances precision, reduces downtime, and improves operator safety. |

| Dust & Noise Control | Integrated water spray and enclosure systems | Meets environmental and regulatory compliance standards. |

These specifications highlight the engineering behind mobile crushing plants. Contractors and mining companies can select units tailored to specific job sizes, materials, and environmental conditions. Whether the goal is processing recycled concrete in urban centers or crushing hard granite in remote quarries, mobile plants adapt with precision.

How Mobile Crushing Plants Support Multiple Industries

The versatility of mobile crushing plants is one of their strongest selling points. By answering the question “How do these plants adapt to different industries?”, we see how they extend value across various sectors:

Construction & Infrastructure

Mobile plants are widely used in road construction, bridge building, and railway development. Their ability to produce on-demand aggregates ensures a steady supply of materials without the delays of external sourcing. Contractors save significantly on transportation, while maintaining control over quality and gradation.

Mining & Quarrying

In mining, efficiency is critical. Mobile crushing plants allow operators to process ore directly at the extraction site, reducing material handling costs. By pairing crushers with on-site screening systems, miners can produce different grades of material with minimal waste.

Demolition & Recycling

Urban projects often generate massive amounts of waste concrete and asphalt. Mobile plants recycle these materials into reusable aggregates, aligning with sustainability goals while reducing landfill usage. This not only benefits the environment but also creates cost-effective materials for new construction.

Agriculture & Rural Development

In certain regions, crushed stone and gravel are vital for rural roads, drainage systems, and agricultural projects. Mobile crushing plants, especially compact models, can be deployed in remote villages to support local infrastructure without heavy transport needs.

Emergency and Temporary Projects

In disaster recovery operations—such as rebuilding roads after floods or earthquakes—mobile crushing plants provide rapid deployment. Their mobility and quick setup allow agencies to produce essential construction materials on-site, accelerating recovery efforts.

By excelling in all these applications, mobile crushing plants demonstrate how they support both long-term industrial operations and urgent short-term projects.

How Mobile Crushing Plants Shape Tomorrow

The global demand for mobile crushing plants is expected to grow steadily as industries prioritize efficiency, sustainability, and flexibility. With increasing investment in infrastructure and a global shift toward greener solutions, the next generation of mobile crushers will feature:

-

Hybrid and electric drives to reduce fossil fuel reliance.

-

Smarter automation systems for predictive maintenance and real-time monitoring.

-

Compact models for urban construction projects.

-

Modular designs that allow quick upgrades and customization.

These innovations ensure that mobile crushing plants remain at the forefront of construction and mining technology.

Common Questions About Mobile Crushing Plants

Q1: How do mobile crushing plants reduce project costs?

Mobile crushing plants eliminate the need to transport raw materials to fixed plants. Instead, they process materials directly on-site, cutting down fuel, labor, and transport costs while ensuring timely material supply. This localized operation also minimizes delays caused by external supply chains.

Q2: How do I choose the right mobile crushing plant for my project?

The right choice depends on material type, required capacity, mobility needs, and environmental considerations. For example, jaw crushers are ideal for primary crushing of hard rock, while impact crushers excel in recycling projects. Evaluating production goals, terrain, and budget ensures the best selection.

Mobile crushing plants have redefined how industries approach construction, mining, and recycling. By offering efficiency, adaptability, and sustainability, they address the pressing demands of modern projects. With advanced specifications, eco-friendly designs, and applications across multiple industries, they prove to be more than just machinery—they are strategic investments.

As a trusted provider in the industry, Zhongjing delivers mobile crushing plants engineered for performance and reliability. Whether your project involves quarrying, infrastructure development, or recycling, our solutions are designed to support success. For detailed specifications, pricing, and customized recommendations, we invite you to contact us today and discover how Zhongjing can empower your operations.