How Does a Gear Box Driven Steel Roll Forming Machine Improve Production Efficiency?

2025-12-08

A Gear Box Driven Steel Roll Forming Machine is widely used in metal fabrication lines because of its stability, precision, and long service life. Compared with traditional chain-driven systems, this gearbox-driven structure ensures smoother transmission, higher torque output, and better accuracy in forming complex steel profiles. As a manufacturer cooperating with Cangzhou Parfu International Trade Co., Ltd., I understand how crucial it is for clients to select a reliable forming solution that guarantees consistent performance. In this article, we will explore its functions, importance, effects, usage benefits, and compare different systems to help users make a better decision.

What Makes a Gear Box Driven Steel Roll Forming Machine Stand Out?

The Gear Box Driven Steel Roll Forming Machine offers superior forming quality thanks to the stable mechanical transmission design. Unlike chain-driven types, gearbox systems reduce vibration and maintain synchronization between stations. This not only improves accuracy but also extends machine lifespan.

Key Advantages

-

Higher torque for forming thicker steel sheets

-

Low maintenance due to sealed gearbox structure

-

Stable and consistent rolling precision

-

Longer lifespan and reduced wear

-

Suitable for high-speed production lines

Why Do I Prefer Gear Box Driven Systems?

Q1: Why would I choose a Gear Box Driven Steel Roll Forming Machine for long-term production?

A1: Because gearbox transmission provides long-term stability and consistency, which reduces the need for frequent adjustments and improves the overall output quality.

Gear Box Driven vs. Chain Driven: Which Is Better?

| Feature | Gear Box Driven | Chain Driven |

|---|---|---|

| Transmission | High stability | Moderate stability |

| Maintenance | Low | Higher maintenance |

| Precision | Excellent | Good |

| Noise | Lower | Higher |

| Lifespan | Longer | Shorter |

From a production standpoint, the difference in stability directly determines product quality. This is why gearbox-driven systems are increasingly preferred by factories requiring consistent accuracy.

What Is the Importance of Using a Gear Box Driven Steel Roll Forming Machine?

The importance lies in its ability to ensure uniform sheet shaping even under heavy-duty conditions. For companies like Cangzhou Parfu International Trade Co., Ltd., offering high-quality forming solutions helps clients enhance production capacity and reduce downtime.

Main Functions

-

Continuous cold roll forming

-

Supporting automatic cutting and leveling

-

Ensuring smooth workflow in long production lines

-

Maintaining precision across multiple forming stations

How Do I Feel About the Machine's Performance?

Q2: How does a Gear Box Driven Steel Roll Forming Machine improve finished product consistency?

A2: In my experience, the gearbox design keeps every station perfectly aligned, avoiding size deviations and ensuring each profile meets the required standards.

Effects and Efficiency of Gear Box Driven Steel Roll Forming Machines

Using a Gear Box Driven Steel Roll Forming Machine significantly enhances output quality and reduces scrap. The high torque transmission allows the machine to work with thicker and harder materials without losing precision.

Usage Effects

-

Smoother profile surfaces

-

Less material waste

-

Faster production speed

-

Lower operational cost per unit

Best Gear Box Driven Steel Roll Forming Features for Industrial Applications

Here are some core features that buyers should look for:

-

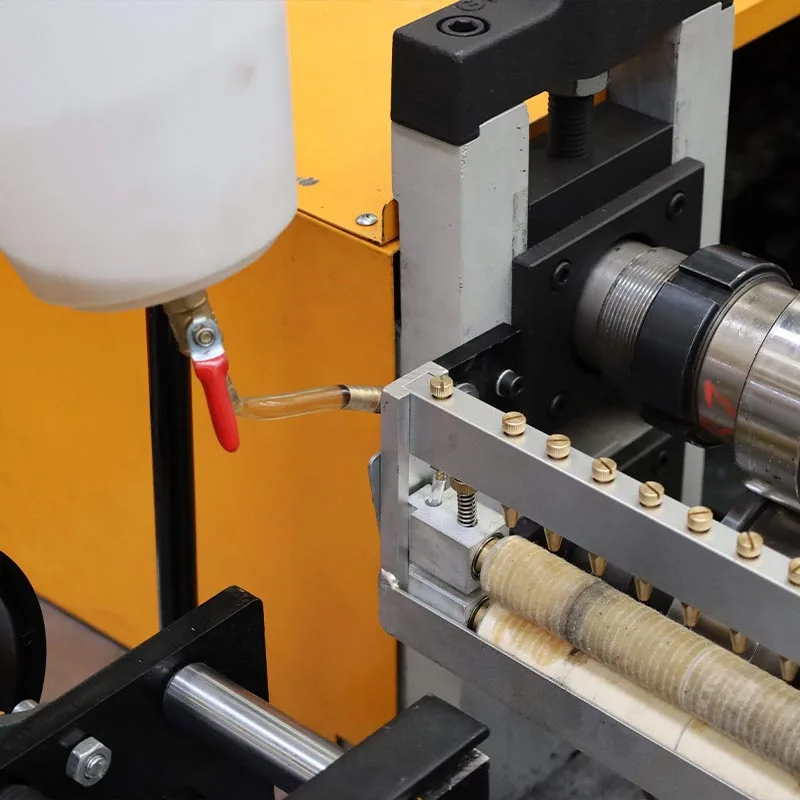

Heavy-duty gearbox system – supports high torque forming

-

Solid machine base – reduces vibration

-

Precision rollers – ensures dimensional accuracy

-

PLC control system – improves automation and efficiency

-

Hydraulic tracking cutting – enhances line productivity

Why Do I Recommend Machines from Cangzhou Parfu International Trade Co., Ltd.?

Q3: Why would I recommend purchasing a Gear Box Driven Steel Roll Forming Machine from Cangzhou Parfu International Trade Co., Ltd.?

A3: Because their machines combine durability, precision engineering, and reliable after-sales support, giving customers confidence in both performance and investment value.

Conclusion

The Gear Box Driven Steel Roll Forming Machine is an essential piece of equipment for modern metal fabrication due to its high precision, low maintenance needs, and long-term durability. Its importance is evident in industries that demand consistent product quality and efficient large-scale production. If you are looking for a reliable solution with strong technical support from Cangzhou Parfu International Trade Co., Ltd., feel free to contact us for professional consultation and customized machine options.