How Does an Air Cooled Chiller Improve Industrial Cooling Efficiency?

2025-12-11

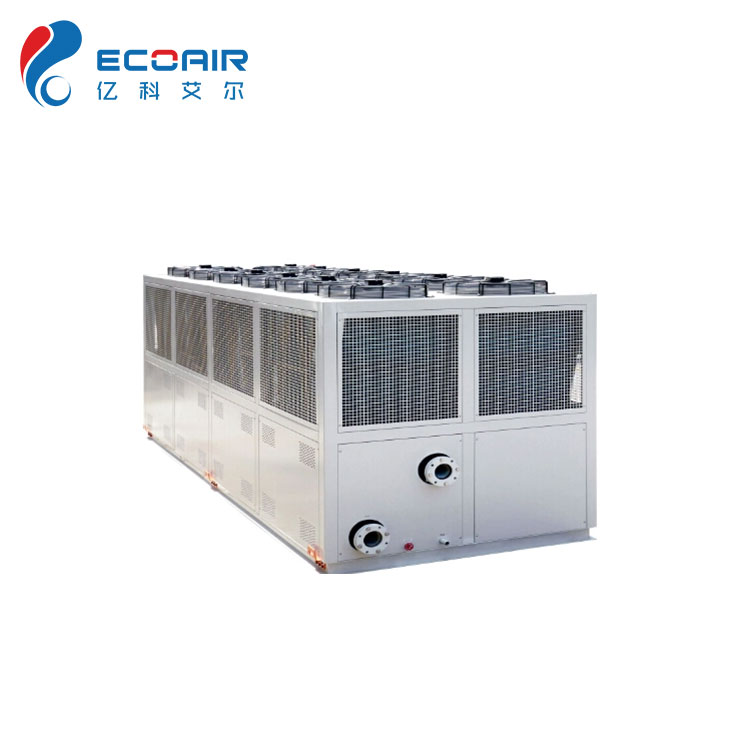

Air Cooled Chillers are critical components in modern industrial and commercial cooling systems, offering efficient heat removal in processes ranging from manufacturing to data center operations. Unlike water-cooled systems, air cooled chillers utilize ambient air to dissipate heat, eliminating the need for extensive water resources and reducing installation complexity. The primary function of an air cooled chiller is to remove heat from a process fluid, typically water or a glycol mixture, and transfer it to the surrounding air through an integrated condenser unit.

Technical Overview and Specifications

Air Cooled Chillers are engineered to provide reliable cooling under varying environmental and operational conditions. The following technical parameters illustrate the capabilities of a typical high-performance unit:

| Parameter | Specification Range |

|---|---|

| Cooling Capacity | 10 kW – 500 kW |

| Refrigerant Type | R410A, R407C, R134a |

| Compressor Type | Scroll, Screw, or Semi-Hermetic |

| Evaporator Type | Shell & Tube / Plate Heat Exchanger |

| Condenser Type | Finned Tube Air-Cooled Condenser |

| Operating Temperature Range | -5°C to 35°C (ambient), -10°C to 25°C (water) |

| Power Supply | 380V-415V / 50Hz-60Hz / 3 Phase |

| Noise Level | 55-70 dB(A) |

| Control System | Microprocessor-based, optional PLC integration |

| Refrigerant Charge | Based on capacity, typically 2-15 kg |

Air cooled chillers are designed for modular installation, allowing flexibility in capacity expansion. The compact design ensures minimal footprint while maintaining high heat rejection efficiency, especially in regions with limited water availability. Additionally, variable speed fans and compressors optimize performance under fluctuating load conditions, significantly reducing energy consumption and improving overall system reliability.

Operational Principles and Applications

How does an air cooled chiller operate to ensure optimal cooling performance?

The operational process begins with the circulation of chilled water or glycol through the evaporator. Heat is absorbed from the fluid and transferred to the refrigerant, which evaporates and carries the absorbed heat to the condenser. In the air cooled condenser, heat is dissipated to the surrounding air via high-efficiency fans and finned tube arrangements. The refrigerant then cycles back to the evaporator to continue the process, maintaining a stable and controlled temperature in the target system.

Air cooled chillers are widely used across various industries, including:

-

Plastic Manufacturing: Maintaining precise mold temperatures to ensure product quality.

-

Food and Beverage Processing: Controlling fermentation and storage temperatures.

-

Data Centers: Reducing server room heat to prevent equipment overheating.

-

HVAC Systems for Commercial Buildings: Providing large-scale space cooling with minimal water usage.

Advanced models incorporate features such as variable speed compressors, energy recovery systems, and smart diagnostics, which enable predictive maintenance and real-time performance monitoring. These features enhance reliability, reduce downtime, and provide cost savings over the equipment’s lifecycle.

Common Questions About Air Cooled Chillers

How often should an air cooled chiller be serviced for optimal performance?

Routine maintenance is recommended every 6 to 12 months, depending on operational load and environmental conditions. This includes inspecting refrigerant levels, cleaning condenser coils, checking compressor operation, and ensuring that all safety controls are functioning properly. Regular maintenance helps prevent efficiency loss, extends equipment life, and reduces the risk of unexpected downtime.

What factors affect the energy efficiency of an air cooled chiller?

Energy efficiency is influenced by ambient temperature, load fluctuations, condenser airflow, and the type of refrigerant used. Optimizing fan speed, maintaining clean heat exchange surfaces, and selecting the correct capacity for the intended application can significantly enhance efficiency. Additionally, implementing variable speed drives and intelligent control systems allows the chiller to operate at partial load with minimal energy waste.

How to troubleshoot common performance issues in air cooled chillers?

Common issues include insufficient cooling, high discharge pressure, or unusual noise. Troubleshooting involves checking for refrigerant leaks, verifying fan operation, ensuring proper airflow around the condenser, and confirming that the compressor operates within manufacturer-specified parameters. Comprehensive monitoring systems can provide early warnings for potential malfunctions, allowing preemptive corrective actions.

How to select the right air cooled chiller for a specific application?

Selecting the appropriate unit requires careful assessment of cooling load, ambient conditions, water flow rate, and space limitations. Engineers should consider both peak and average load demands, energy efficiency ratings, and compliance with local regulations. Consulting technical datasheets and manufacturer guidance ensures that the selected chiller meets both operational and environmental requirements.

Future Outlook and Brand Expertise

Air cooled chillers are expected to evolve with increasing focus on energy efficiency, environmental compliance, and smart integration. Emerging trends include the adoption of low-GWP refrigerants, advanced inverter-driven compressors, and predictive analytics for real-time monitoring. As industrial and commercial facilities seek sustainable solutions, air cooled chillers offer a practical choice that balances performance, environmental impact, and operational cost.

Ningbo Ecoair Environmental Technology Co., Ltd specializes in providing reliable and efficient air cooled chiller systems for diverse industrial and commercial applications. Their products are engineered for high performance, minimal maintenance, and long-term durability. For more information on selecting the right air cooled chiller or to discuss customized solutions, contact us today to connect with our technical experts.