How Does High Speed Converting Machinery Revolutionize Production Efficiency

2025-10-09

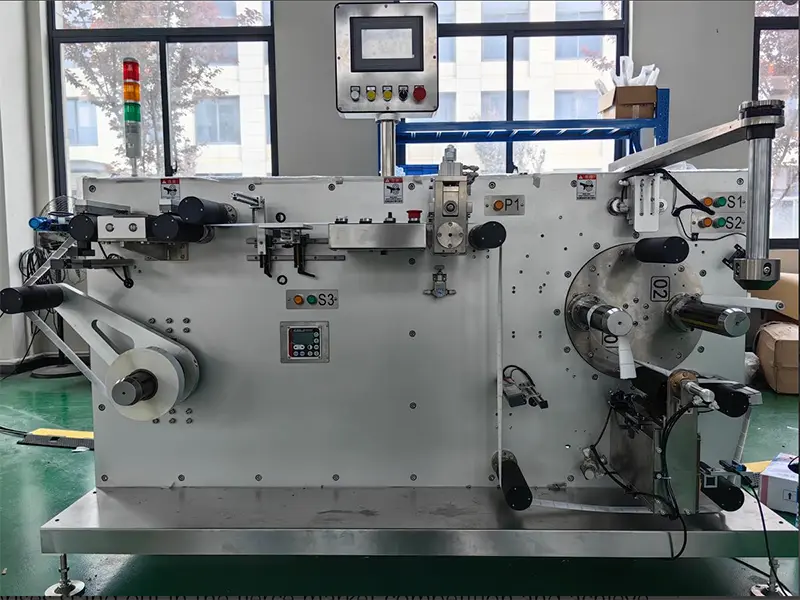

When I first joined WEIJU, one thing quickly became clear—manufacturers around the world were struggling with slow, inconsistent, and labor-intensive roll converting processes. That’s why we developed our Auto Roll To Roll Rewinder Machine, a high-performance solution designed to meet the growing demand for automation, precision, and speed in converting lines.

What Makes Our High Speed Converting Machinery Different

Unlike traditional rewinder systems, our machinery focuses on optimizing line stability, material adaptability, and operational simplicity. Each detail—from motor control to web alignment—is engineered for precision and productivity. Here’s what sets our system apart:

- Servo-driven automatic tension control for perfect roll formation

- Intelligent web guiding system ensuring consistent alignment

- Automatic roll changing to minimize downtime

- Compatible with multiple materials including paper, film, and foil

- User-friendly HMI interface for real-time monitoring

What Are the Core Technical Specifications

To help you understand the performance level of our machine, here are the detailed parameters of the WEIJU High Speed Converting Machinery:

| Parameter | Specification |

|---|---|

| Model | WJ-RR1200 |

| Material Width | Up to 1200 mm |

| Rewinding Diameter | Max 600 mm |

| Speed | Up to 400 m/min |

| Tension Range | 3–30 kg |

| Core Diameter | 3" / 6" optional |

| Power Supply | 380V / 50Hz |

| Control System | PLC + Touch Screen |

| Drive Type | Servo Motor Control |

| Applicable Materials | Paper, Film, Aluminum Foil, Nonwoven |

Why Do Businesses Choose WEIJU for Converting Solutions

From my experience working with production managers, three major pain points keep coming up—frequent roll changeovers, uneven tension control, and wasted materials. Our equipment directly addresses these challenges:

- Reduced Waste: Optimized web path design and stable rewinding tension cut down on scrap rates.

- Higher Output: Continuous roll operation with automated roll change reduces idle time.

- Consistent Quality: Intelligent control systems maintain tension accuracy even at high speeds.

- Flexible Operation: Adjustable settings allow quick adaptation for different materials and roll sizes.

How Does It Improve Production Efficiency

Every manufacturer aims to increase throughput without sacrificing quality. Our high-speed converting machine is not just faster—it’s smarter. The automated features save labor, while the precision control ensures repeatable results, shift after shift. Over time, this translates to lower production costs and faster return on investment.

How Can You Get a Customized Solution

At WEIJU, we don’t believe in one-size-fits-all machinery. Each client’s production setup is unique, so our engineering team customizes machine configurations to fit your exact needs. Whether you handle lightweight films or heavy-duty industrial paper, we can tailor parameters like web width, roll diameter, and drive power for optimal performance.

Ready to Upgrade Your Converting Line

If your current production line struggles with inefficiency, waste, or frequent maintenance, our team is here to help. Reach out today to learn more about how WEIJU’s High Speed Converting Machinery can transform your operations. Contact us now for a detailed quotation or to discuss your production requirements—let’s make your converting process faster, smarter, and more reliable.