How HDPE PE COD Cable Porous Pipe Making Machine Drives Efficient Cable Infrastructure Manufacturing

2025-12-31

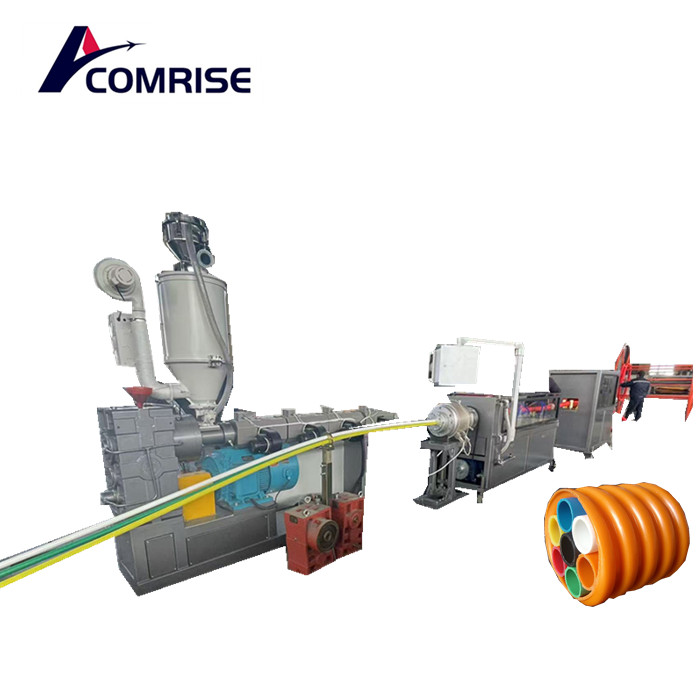

With the rapid expansion of urbanization, smart cities, and underground cable networks, the demand for high-quality cable protection solutions continues to rise. HDPE and PE COD porous pipes have become a preferred choice for telecom, power, and data cable installations due to their durability, flexibility, and excellent protection performance. Against this background, the HDPE PE COD Cable Porous Pipe Making Machine plays a critical role in ensuring consistent quality, high output, and cost-effective production. As an experienced manufacturer, Qingdao Comrise Machinery Co., Ltd. provides advanced extrusion solutions designed to meet both technical and commercial demands of modern pipe producers.

What Is an HDPE PE COD Cable Porous Pipe Making Machine?

The HDPE PE COD Cable Porous Pipe Making Machine is a specialized extrusion line designed to produce multi-hole (porous) HDPE or PE pipes used for cable protection and routing. These pipes allow multiple cables to be laid simultaneously, improving construction efficiency and reducing overall project costs. The machine integrates extrusion, mold forming, vacuum calibration, cooling, traction, and cutting into one continuous and automated production process.

Dual-Level Headline: Function and Value

Core Function

The main function of this machine is to continuously produce HDPE or PE COD porous pipes with precise hole structure, stable dimensions, and smooth inner and outer surfaces.

Value to Manufacturers

For manufacturers, the value lies in high production efficiency, reduced material waste, stable long-term operation, and the ability to meet strict engineering standards required by telecom and power industries.

Key Components and Technical Features

A typical production line supplied by Qingdao Comrise Machinery Co., Ltd. includes the following modules:

-

High-efficiency single-screw extruder for HDPE/PE materials

-

Precision porous pipe die head

-

Vacuum calibration and cooling tank

-

Haul-off unit with stable traction

-

Automatic cutting system

-

Intelligent PLC control system

Simple Technical Overview Table

| Item | Description |

|---|---|

| Applicable Material | HDPE / PE |

| Pipe Type | COD multi-hole porous pipe |

| Control System | PLC + touch screen |

| Production Mode | Continuous extrusion |

| Application | Cable protection & routing |

Why Is This Machine Important?

The importance of the HDPE PE COD Cable Porous Pipe Making Machine goes beyond simple pipe production. It directly impacts infrastructure quality and construction efficiency.

-

Improved Cable Management: Multi-hole design allows organized cable routing.

-

Lower Construction Costs: Fewer excavation cycles and faster installation.

-

Enhanced Protection: HDPE/PE materials offer corrosion resistance and long service life.

-

Scalable Production: Suitable for both medium and large-scale manufacturers.

Practical Effects and Usage Results

In real-world applications, manufacturers using Comrise machinery report:

-

Stable pipe wall thickness and hole alignment

-

Reduced rejection rate during quality inspection

-

Consistent output suitable for long-distance projects

-

Strong market competitiveness due to reliable product quality

These results help customers quickly respond to infrastructure projects such as 5G networks, urban power grids, and industrial parks.

Why Choose Qingdao Comrise Machinery Co., Ltd.?

Qingdao Comrise Machinery Co., Ltd. combines engineering expertise with market-oriented design. The company focuses on:

-

Customized solutions for different COD pipe specifications

-

Energy-saving and user-friendly machine design

-

Reliable after-sales technical support

-

Long-term cooperation mindset with global customers

By integrating advanced technology and practical manufacturing experience, Comrise ensures that every HDPE PE COD Cable Porous Pipe Making Machine delivers both technical excellence and commercial value.

Conclusion

As cable infrastructure continues to evolve, efficient and reliable production equipment becomes a decisive factor for success. The HDPE PE COD Cable Porous Pipe Making Machine offers manufacturers a powerful tool to produce high-quality porous pipes with efficiency, consistency, and profitability. Partnering with Qingdao Comrise Machinery Co., Ltd. means investing in proven technology and professional support that helps your business grow in competitive markets.

If you are looking to upgrade your production line or start a new COD pipe project, contact us today to explore customized solutions and professional guidance.