How to Choose the Right Manual Cap Threading Machine?

2026-01-07

Article Summary: Manual Cap Threading Machines are essential for industries that require precise capping and threading of bottles and containers. This article provides a comprehensive guide covering product specifications, operational insights, and answers to common questions to help professionals make informed decisions.

Table of Contents

- 1. Introduction to Manual Cap Threading Machine

- 2. Key Specifications and Technical Details

- 3. Common Questions About Manual Cap Threading Machine

- 4. How to Optimize Usage and Where to Get Feihong Machines

1. Introduction to Manual Cap Threading Machine

Manual Cap Threading Machines are widely utilized in industries such as beverage, pharmaceutical, and cosmetic manufacturing to ensure precise threading of caps on bottles or containers. These machines are manually operated, providing flexibility, control, and cost-efficiency for small to medium production lines.

The main purpose of this guide is to help industrial buyers, operators, and engineers understand the critical aspects of Manual Cap Threading Machines, including technical specifications, practical usage, and troubleshooting tips.

2. Key Specifications and Technical Details

When selecting a Manual Cap Threading Machine, it is essential to consider parameters that affect efficiency and product compatibility. Below is a detailed table summarizing the key specifications:

| Parameter | Specification |

|---|---|

| Machine Type | Manual Cap Threading |

| Cap Diameter Range | 15mm – 50mm |

| Bottle Height Compatibility | 50mm – 300mm |

| Material | Stainless Steel / Aluminum Alloy |

| Operation Mode | Hand-Operated Lever |

| Production Capacity | 50 – 150 bottles per hour (depending on operator speed) |

| Adjustable Threading Torque | Yes, up to 5 Nm |

| Weight | Approx. 20 kg |

| Dimensions | 400mm x 300mm x 450mm |

These parameters ensure compatibility with a variety of bottle types and production scales. Users should carefully evaluate their production line requirements and the machine’s adjustability features.

3. Common Questions About Manual Cap Threading Machine

Q1: How to adjust the machine for different cap sizes?

A1: Manual Cap Threading Machines come with adjustable threading heads. Operators can loosen the clamping knobs, move the threading head to match the cap diameter, and re-tighten securely. Testing with a sample bottle is recommended before full-scale operation to ensure proper alignment and torque.

Q2: How to maintain consistent threading torque?

A2: Consistent threading torque is achieved by calibrating the torque lever based on the cap material and size. Regular lubrication of moving parts and periodic inspection of spring mechanisms help maintain uniform pressure during threading, preventing cap deformation or leakage.

Q3: How to prevent damage to fragile bottles during manual threading?

A3: To prevent breakage, operators should adjust the machine for minimal torque necessary to secure the cap. Using a soft rubber insert or adjustable support for the bottle base helps absorb excess pressure. Training operators on steady hand movement and proper lever control is crucial for fragile container handling.

4. How to Optimize Usage and Where to Get Feihong Machines

Optimizing the use of Manual Cap Threading Machines involves understanding production needs, operator training, and regular maintenance. Proper alignment of the bottle, controlled threading speed, and periodic inspection of machine components are critical steps to ensure long-term reliability.

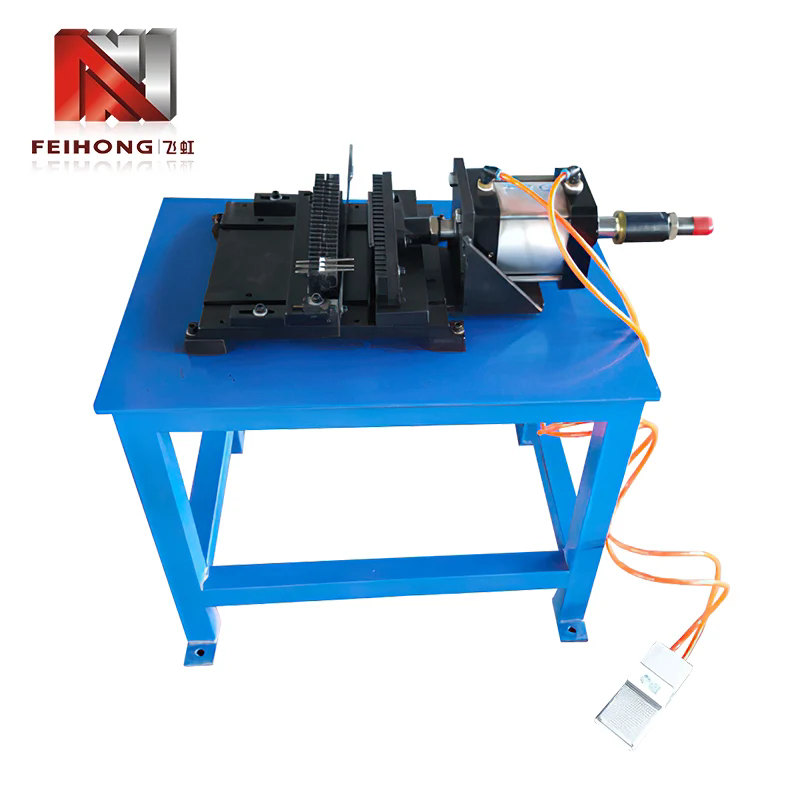

Feihong offers a wide range of Manual Cap Threading Machines designed for small to medium-scale production lines. With robust build quality and versatile adjustment options, Feihong machines cater to different industries requiring precise and efficient cap threading solutions.

For inquiries or purchasing details, contact us directly to explore the full range of Feihong Manual Cap Threading Machines and receive tailored guidance for your production requirements.