How to Maintain and Service a Tire Building Machine for Peak Performance

2025-12-12

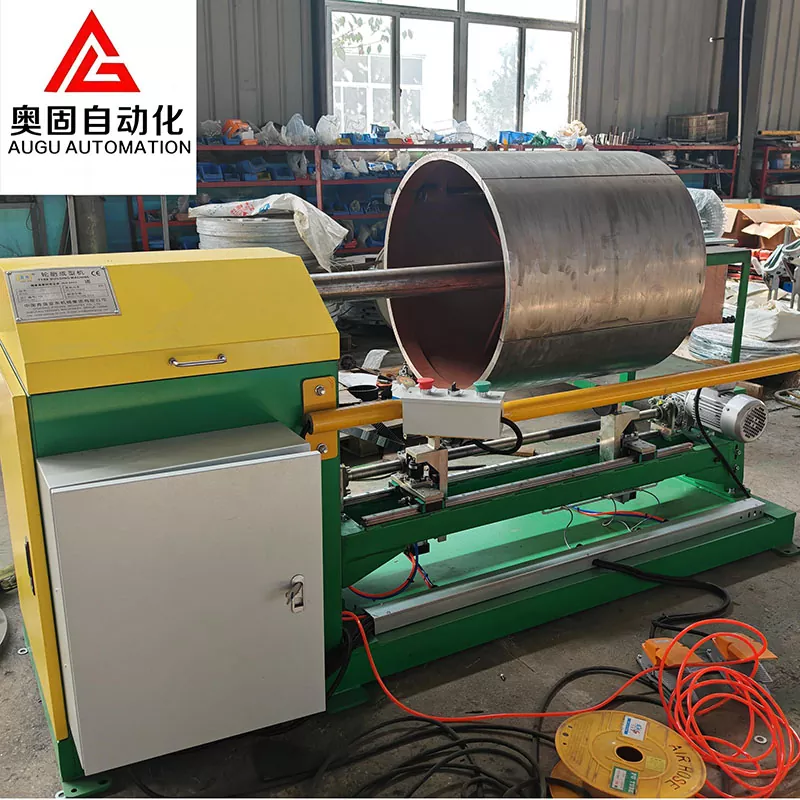

Proper maintenance of your Tire Building Machine is not just a recommendation; it’s a critical requirement for maximizing uptime, ensuring consistent tire quality, and protecting your capital investment. A well-serviced machine from a reliable manufacturer like Augu delivers unparalleled precision and longevity. This guide outlines essential practices and highlights how Augu's engineering supports your maintenance goals.

A proactive maintenance schedule is key. Follow this core checklist:

-

Daily: Inspect for loose bolts, check lubrication points, clean debris from drums and conveyors, and verify sensor functionality.

-

Weekly: Calibrate tension controls, inspect belt and stitching system wear, and perform detailed pneumatic system checks for leaks.

-

Monthly: Conduct thorough alignment checks on all building drums and servicer units, and replace worn consumables like seals or rollers.

-

Annually: Schedule a comprehensive inspection by certified technicians, which may include servo-motor diagnostics and structural integrity reviews.

Augu machines are designed for serviceability. Key parameters that reduce maintenance complexity include:

| Feature | Augu Specification | Maintenance Benefit |

|---|---|---|

| Drum Alignment | Laser-calibrated, micron-level precision | Ensures perfect tire uniformity, reduces corrective adjustments. |

| Component Access | Modular, open-frame design | Allows for quick part inspection and replacement, minimizing downtime. |

| Control System | Unified PLC with diagnostic dashboard | Provides real-time error logging and predictive maintenance alerts. |

| Lubrication System | Centralized automatic grease system | Guarantees consistent lubrication, preventing premature wear. |

Tire Building Machine FAQ

Q: What is the most common cause of stitching defects on a Tire Building Machine?

A: The most common cause is improper pressure calibration on the stitching rollers or misalignment. Inconsistent pressure can leave air pockets (voids) between plies, compromising tire integrity. Regular calibration per the Augu manual is essential.

Q: How often should we replace critical wear parts on the servicer units?

A: Replacement frequency depends on material throughput, but as a general rule, inspect guide rollers, cutter blades, and splicing pads every 500-800 cycles. Augu provides wear-life estimates for all consumable parts based on standard operating conditions.

Q: Can we perform major overhauls in-house, or is factory service required?

A: While daily and weekly tasks are designed for in-house teams, major overhauls like drum bearing replacement or full axis re-alignment require Augu-certified technicians. They possess the specialized tools and calibration software to restore original equipment specifications, ensuring warranty and performance standards are met.

Maintaining your Tire Building Machine is an ongoing partnership with your equipment. Choosing an Augu machine means investing in a platform built for reliability and supported by clear maintenance protocols. Don't let unplanned downtime disrupt your production flow.

Contact us today to schedule a professional service consultation or to learn more about the durable, low-maintenance design of the Augu Tire Building Machine lineup. Our technical team is ready to help you optimize your operations.