How to Make Hollow Block Machine

2025-09-09

Welcome to this comprehensive guide on how hollow block machines are manufactured and what makes a high-quality machine. In this article, we will explore the engineering process, key components, and technical specifications of hollow block machine production. We’ll also provide detailed product parameters and comparisons to help you understand why QGM’s machines stand out in the industry. Whether you are a construction business owner, an engineer, or someone looking to invest in brick-making equipment, this guide will offer valuable insights.

Understanding Hollow Block Machines

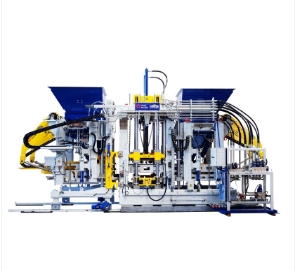

A hollow block machine is a specialized piece of equipment used to produce hollow concrete blocks, which are widely used in construction for their strength, insulation properties, and cost-effectiveness. These machines combine vibration, pressure, and automation to form blocks with consistent size and density. The manufacturing process involves several critical steps, including raw material preparation, mixing, molding, curing, and palletizing.

At QGM, we leverage over two decades of engineering expertise to produce robust and efficient hollow block machines. Our machines are designed to meet international standards, ensuring durability, high output, and ease of operation.

Key Components of a Hollow Block Machine

To understand how a hollow block machine is made, it’s essential to know its core components:

-

Hopper: Stores and feeds raw materials like cement, sand, and aggregates into the mixer.

-

Mixer: Blends materials with water to form a homogeneous concrete mixture.

-

Conveyor System: Transports the mixed concrete to the molding area.

-

Molding System: Uses vibration and hydraulic pressure to compact the concrete into block shapes.

-

Hydraulic Unit: Provides the necessary pressure for compaction and ejection of blocks.

-

Control System: Automated PLC-based panel for monitoring and adjusting machine operations.

-

Pallet Feeder and Stacker: Handles the movement and stacking of finished blocks.

Each component must be precision-engineered to ensure seamless operation and high productivity.

How QGM Hollow Block Machines Are Manufactured

QGM follows a stringent manufacturing process to build reliable hollow block machine models. Here’s an overview:

-

Design Phase: Our engineers use CAD software to create detailed designs, focusing on structural integrity and functionality.

-

Material Selection: High-grade steel and wear-resistant parts are used to enhance longevity.

-

Fabrication: Components are cut, welded, and assembled with precision machinery.

-

Quality Testing: Every machine undergoes rigorous testing for performance, safety, and efficiency.

-

Automation Integration: Advanced control systems are installed to optimize operation and reduce manual labor.

This process ensures that every hollow block machine from QGM delivers exceptional performance and reliability.

Technical Parameters of QGM Hollow Block Machines

Below, we list the key specifications of our popular hollow block machine models. These parameters are critical for evaluating the machine’s capability and suitability for your projects.

Model: QGM Zenith 1500

| Parameter | Value |

|---|---|

| Production Capacity (blocks per hour) | 1,500 |

| Power Consumption | 45 kW |

| Operating Pressure | 210 bar |

| Vibration Frequency | 3,000 RPM |

| Mold Cycle Time | 20-25 seconds |

| Pallet Size | 1,100 x 550 mm |

| Machine Weight | 8,500 kg |

| Automation Level | Fully Automatic |

Model: QGM Zenith 3000

| Parameter | Value |

|---|---|

| Production Capacity (blocks per hour) | 3,000 |

| Power Consumption | 65 kW |

| Operating Pressure | 250 bar |

| Vibration Frequency | 3,500 RPM |

| Mold Cycle Time | 15-20 seconds |

| Pallet Size | 1,200 x 600 mm |

| Machine Weight | 10,200 kg |

| Automation Level | Fully Automatic with Smart Control |

These specifications highlight the efficiency and power of QGM machines, designed for high-volume production and minimal downtime.

Advantages of Choosing QGM Hollow Block Machines

-

High Efficiency: Our machines produce up to 3,000 blocks per hour, reducing project timelines.

-

Durability: Built with reinforced steel and quality components for long-term use.

-

Energy Saving: Optimized hydraulic systems lower power consumption.

-

User-Friendly: Automated controls make operation straightforward, even for beginners.

-

Low Maintenance: Easy access to parts and comprehensive service support.

Comparison Table: QGM vs. Competitors

| Feature | QGM Zenith Series | Typical Competitor Machines |

|---|---|---|

| Production Capacity | 1,500 - 3,000 blocks/hour | 800 - 2,000 blocks/hour |

| Automation | Fully automatic with PLC | Semi-automatic or manual |

| Energy Efficiency | High | Moderate |

| Warranty | 2 years | 1 year |

| After-Sales Service | Global support network | Limited availability |

This comparison demonstrates why QGM’s hollow block machine models are a superior choice for serious builders and contractors.

Conclusion

Investing in a high-quality hollow block machine is crucial for the success of your construction projects. At QGM, we pride ourselves on delivering machines that combine innovation, reliability, and efficiency. Our technical expertise and commitment to quality ensure that you get the best value for your investment.

I encourage you to reach out to us for more information or to discuss your specific needs. Leave an inquiry at [email protected], and let’s build something great together.