What Are the Key Parameters to Consider When Selecting a Rubber Block Chain

2025-11-26

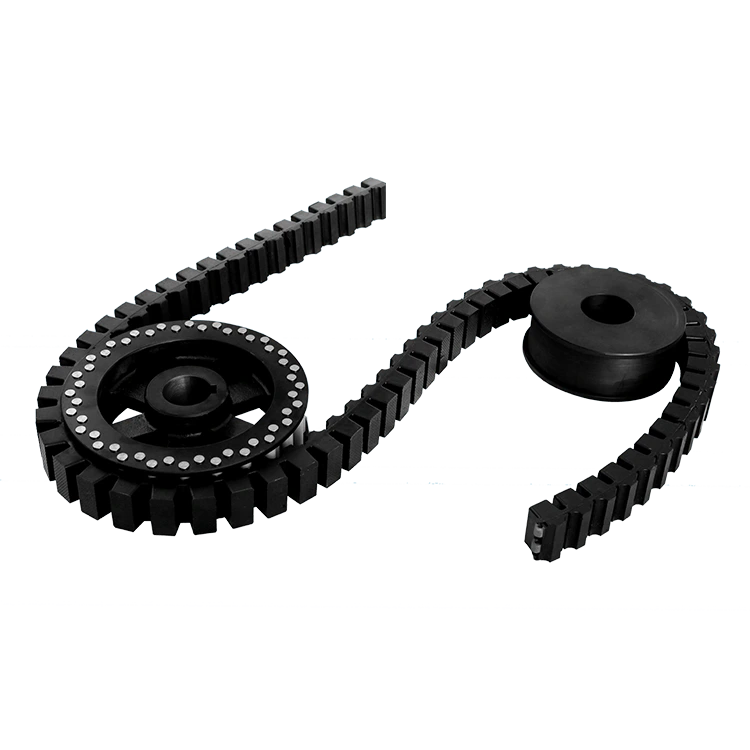

Choosing the right conveyor component is critical for operational efficiency and cost savings. When it comes to Rubber Block Chain systems, making an informed decision requires a deep understanding of several key technical parameters. Selecting the wrong chain can lead to premature wear, unplanned downtime, and increased maintenance costs. This guide will walk you through the essential factors to consider, ensuring you select a chain that delivers maximum performance and longevity for your application. As a leader in innovative conveying solutions, SHUKAI has engineered its Rubber Block Chain products to excel across these critical parameters, providing unmatched reliability.

To ensure a perfect match for your system, focus on these core specifications:

-

Pitch Size: This is the distance between the centers of two consecutive pins. A larger pitch generally allows for higher conveying speeds but can affect the chain's flexibility and smoothness.

-

Block Hardness: Measured in Durometer Shore A, this determines the chain's resistance to wear, its grip on the product, and its noise levels. Softer compounds offer better grip and less noise, while harder compounds provide superior abrasion resistance.

-

Tensile Strength: The maximum load the chain can withstand in a straight pull before breaking. This is a fundamental indicator of the chain's overall strength and durability.

-

Overall Width and Height: The physical dimensions of the chain must be compatible with your existing or planned conveyor framework and guides.

For a quick comparison, here are typical specifications for a SHUKAI Rubber Block Chain series:

| Parameter | Specification | Importance |

|---|---|---|

| Pitch | 3.25 inches | Balances speed capability with smooth operation |

| Block Hardness | 85 Shore A | Optimal blend of abrasion resistance and product grip |

| Tensile Strength | 40,000 lbs | Ensures reliability under high-tension conditions |

| Max Recommended Speed | 150 ft/min | Provides guidance for efficient system operation |

| Temperature Range | -10°F to 180°F | Suitable for a wide variety of industrial environments |

Rubber Block Chain FAQ

What industries are SHUKAI Rubber Block Chains best suited for?

SHUKAI Rubber Block Chains are highly versatile and are successfully implemented in numerous industries. They are particularly well-suited for food and beverage processing due to their clean operation and corrosion resistance, packaging for their quiet and efficient movement, and agriculture for their durability and excellent grip on inclined surfaces.

How does the lubrication-free feature of a Rubber Block Chain benefit my operation?

The inherent self-lubricating properties of the Rubber Block Chain material eliminate the need for external lubricants. This leads to a cleaner work environment by preventing product contamination, significantly reduces maintenance time and costs associated with lubrication schedules, and minimizes the environmental impact of oil and grease disposal.

Can a SHUKAI Rubber Block Chain be used to replace a traditional metal chain?

In many cases, yes. SHUKAI Rubber Block Chains are designed as direct replacements for many standard metal chains. They offer superior benefits including significant noise reduction, natural grip that prevents product slippage, and inherent corrosion resistance. It is crucial to verify the physical dimensions and tensile strength requirements with a SHUKAI engineer to ensure a seamless and successful retrofit.

Selecting the right Rubber Block Chain is a technical decision that directly impacts your bottom line. By carefully evaluating these key parameters, you can specify a component that enhances productivity and reduces total cost of ownership. The engineered solutions from SHUKAI are built to meet these rigorous demands, providing a reliable and high-performing choice for your conveying needs.

Contact us today to discuss your specific application requirements. Our technical experts at SHUKAI are ready to help you analyze your needs and recommend the perfect Rubber Block Chain to optimize your conveyor system's performance and durability.