What is the Load Capacity Range for Mini Lever Hoists

2026-01-05

When precision and power are needed in confined spaces, the Mini Type Lever Hoist is an indispensable tool for professionals. Understanding its load capacity is crucial for selecting the right equipment and ensuring job site safety. As a leader in engineered lifting solutions, BaiYi is committed to providing not only superior products but also the essential knowledge for their effective and safe application. This guide will explore the typical load range of these compact workhorses and what factors influence their performance.

The load capacity of a mini lever hoist defines its core capability. Unlike their larger counterparts, these tools are engineered for lighter, more precise tasks.

-

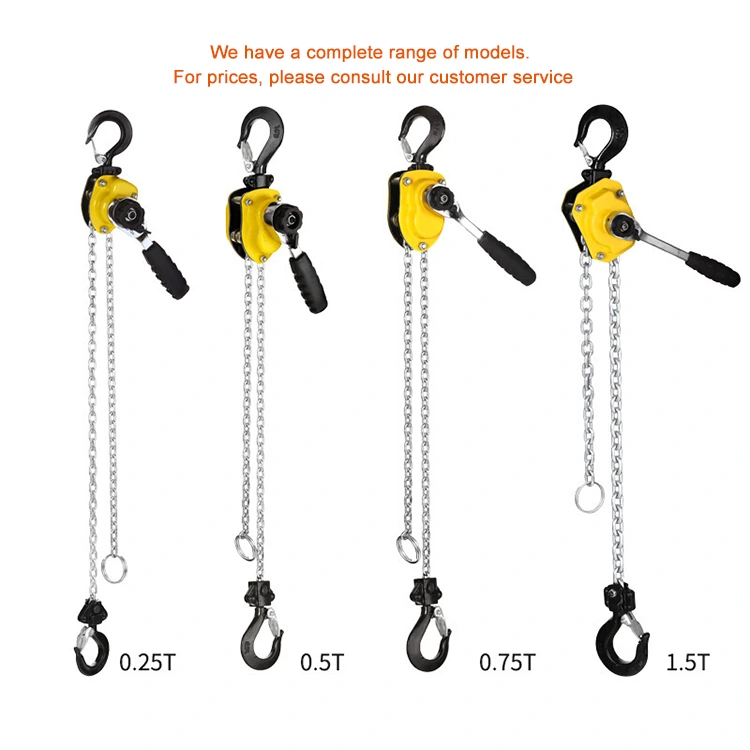

Typical Range: Most standard models offer a capacity range from 0.25 tons (500 lbs) to 2 tons (4,000 lbs). The most popular models for general maintenance, construction, and manufacturing often sit in the 0.75-ton to 1.5-ton range.

-

Critical Factor - Safety: It is paramount to never exceed the Working Load Limit (WLL) clearly marked on the hoist. BaiYi hoists are designed with a built-in safety factor, but consistent overloading leads to premature wear and potential failure.

Choosing the correct capacity depends on your specific needs. The following table outlines common applications matched with suggested capacities:

| Application Scenario | Recommended Mini Lever Hoist Capacity | Key Considerations |

|---|---|---|

| Workshop Machine Alignment | 0.25 Ton - 0.5 Ton | Precision positioning requires fine control, not extreme weight. |

| Automotive Component Lifting | 0.75 Ton - 1 Ton | Perfect for engines, transmissions, or vehicle positioning. |

| Construction Material Handling | 1 Ton - 1.5 Ton | Ideal for lifting bundles of steel, timber, or HVAC units. |

| Stage and Rigging Setup | 0.5 Ton - 2 Ton | Depends on lighting and sound equipment weight. |

Mini Type Lever Hoist FAQ

Q: Can I use a mini lever hoist for vertical lifting and horizontal pulling?

A: Yes, absolutely. One of the key advantages of a Mini Type Lever Hoist is its versatility. It is designed for both vertical lifting and horizontal pulling applications, such as tensioning lines, dragging equipment, or positioning machinery. Always ensure the load path is clear and the anchor points are secure for the direction of force.

Q: How often should I inspect my mini lever hoist?

A: A formal pre-operation inspection should be performed before each use, checking for damaged hooks, twisted chains, and proper operation. A comprehensive periodic inspection, as per the manufacturer's guidelines (e.g., monthly or quarterly), should be conducted by competent personnel. BaiYi recommends following a strict inspection regimen to guarantee safety and longevity.

Q: What maintenance does a mini lever hoist require?

A: Regular maintenance is simple but critical. It primarily involves keeping the chain clean and lightly lubricated with a suitable grease, ensuring the lever mechanism moves freely without grit, and storing the unit in a dry, clean environment. Always refer to the BaiYi user manual for model-specific maintenance procedures.

Selecting the right Mini Type Lever Hoist with the appropriate load capacity is the foundation of efficient and safe material handling. By matching the tool to the task and adhering to rigorous safety protocols, you maximize productivity and protect your workforce. For detailed specifications on our reliable and certified range of hoists, or for expert advice on your specific lifting challenges, contact us today. Our team at BaiYi is ready to support your projects with professional solutions.