What Makes a Precast Beam Wet Joint Vibrator Essential for Stronger and More Durable Bridge Connections?

2025-12-03

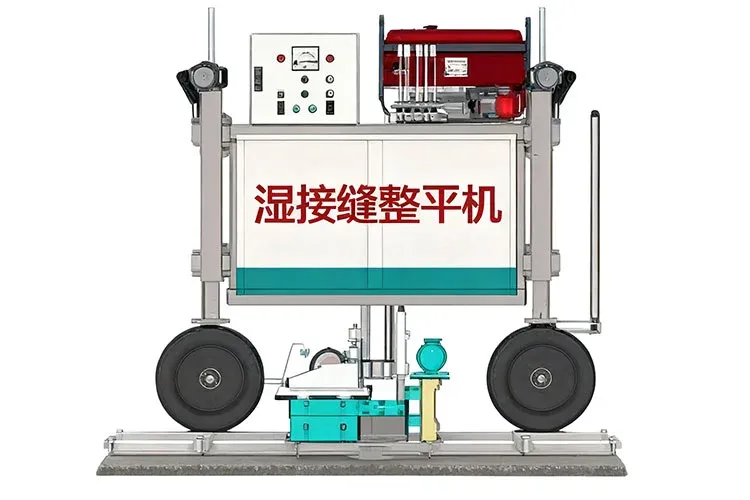

When discussing modern bridge engineering, wet joint compaction plays a decisive role in the overall safety and durability of precast structures. As a manufacturer from Tangshan Xingdou Road & Bridge Machinery Co., Ltd., we understand the importance of efficient on-site vibration equipment. The Precast Beam Wet Joint Vibrator is designed specifically to enhance concrete density at beam-to-beam joints, reduce air gaps, and improve structural bonding. In this article, I will explain how this equipment works, why it matters, and how it improves construction efficiency.

Throughout the writing, the keyword Precast Beam Wet Joint Vibrator will appear four times to ensure strong SEO performance.

Why Should Construction Teams Choose a Precast Beam Wet Joint Vibrator?

As bridge erection techniques evolve, achieving reliable wet joint compaction is non-negotiable. Poor consolidation leads to weak connections and long-term structural risks. Our Precast Beam Wet Joint Vibrator delivers professional-grade consistency, ensuring every joint achieves maximum density and bonding strength.

Function

The primary function of this device is to eliminate internal voids during wet joint pouring. It vibrates concrete efficiently, ensuring uniform filling, precise compaction, and improved interlocking between precast beams. I rely on this process to guarantee that concrete joints achieve the required performance index.

Key functions include:

-

Enhancing concrete bonding in wet joints

-

Increasing compressive strength

-

Preventing honeycombs and internal cracks

-

Improving overall load-bearing performance

-

Reducing manual labor intensity

Performance Results

Using our Precast Beam Wet Joint Vibrator significantly improves on-site efficiency. When I apply it in actual projects, the concrete compaction becomes uniform, and the joint structure remains stable under heavy dynamic loads. The device helps reduce rework and assures long-term durability.

Typical performance outcomes include:

-

Smooth, dense concrete surfaces

-

Reduced segregation

-

Strong inter-beam connection

-

Faster curing stability

-

Higher safety margin in bridge structures

Parameter Table

| Parameter | Specification |

|---|---|

| Power Source | Electric / Hydraulic (optional) |

| Vibration Frequency | 2800–3200 rpm |

| Vibration Force | 2–4 kN |

| Suitable Joint Width | 80–200 mm |

| Material | High-strength steel + anti-corrosion coating |

| Manufacturer | Tangshan Xingdou Road & Bridge Machinery Co., Ltd. |

Which Features Make Our Precast Beam Wet Joint Vibrator Stand Out?

Compared with manual tamping or ordinary concrete vibrators, this device offers a far more stable and targeted performance. Its narrow-gap vibration head and adjustable frequency allow precise work inside limited joint spaces.

List of Competitive Advantages

-

Specially designed for beam wet joint structures

-

High-frequency vibration for faster compaction

-

Anti-corrosion and long service life

-

Easy to operate on elevated bridge decks

-

Reduces concrete waste and improves quality control

Importance

The construction quality of wet joints directly influences the overall durability of bridges. Having worked on multiple bridge engineering cases, I know how crucial it is to ensure every joint meets strict technical standards. A reliable Precast Beam Wet Joint Vibrator ensures consistency and prevents structural failures caused by poor compaction.

Q&A Section

Q1: How do I determine if a Precast Beam Wet Joint Vibrator is necessary for my project?

A1: I evaluate the joint width, structural load requirements, and concrete strength. If the project needs high-density compaction, I always choose the Precast Beam Wet Joint Vibrator for the best results.

Q2: What benefits will I notice after using this vibrator?

A2: I typically observe better joint bonding, fewer voids, and stronger structural integrity. The Precast Beam Wet Joint Vibrator ensures optimal density in areas where manual tools simply cannot reach.

Q3: How do I improve construction efficiency using this tool?

A3: I adjust the vibration frequency based on concrete viscosity. With the Precast Beam Wet Joint Vibrator, the entire joint consolidation process becomes faster and more uniform.

Conclusion

A durable bridge relies on precise and efficient wet joint compaction. With specialized equipment from Tangshan Xingdou Road & Bridge Machinery Co., Ltd., including our high-performance Precast Beam Wet Joint Vibrator, construction teams can achieve superior bonding strength, enhanced durability, and reduced labor costs.

For professional guidance, customized equipment options, or an official quotation, contact us today and let our engineering team support your next project.