What Makes a Straightening Machine Essential for Modern Metal Processing?

2025-12-03

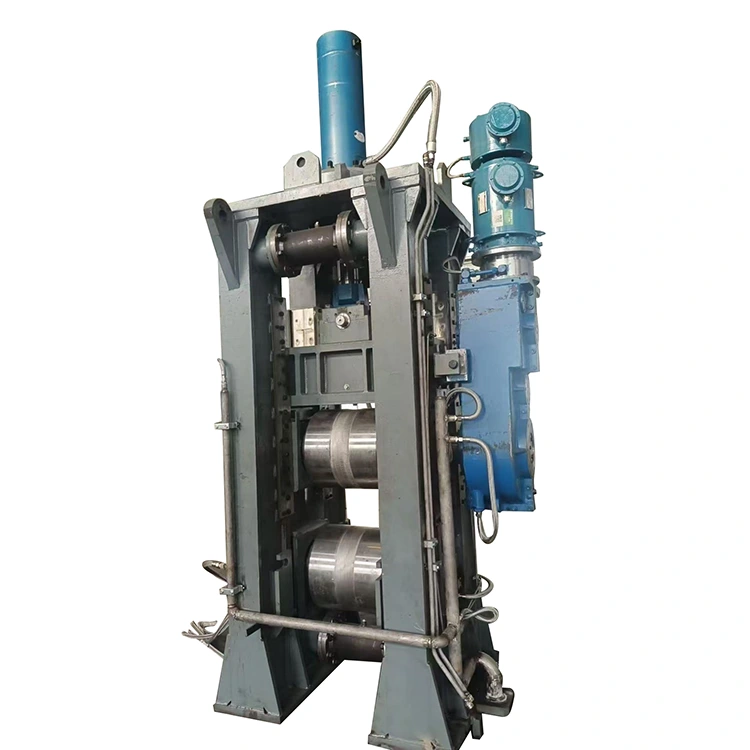

In today's manufacturing industry, improving material accuracy and productivity has become a top priority. A Straightening Machine plays a crucial role in achieving precise metal correction, ensuring that raw materials meet high-level production standards. As someone who has personally worked with various metal processing systems, I know how important stable straightening equipment is for high-speed production lines. At Tangshan Yuexin Machinery Manufacturing Co., Ltd., our focus is to provide reliable, efficient, and well-engineered straightening solutions for global industries.

Understanding the Role of a Straightening Machine

A Straightening Machine is designed to correct the curvature, twist, and deformation in metal sheets, bars, and profiles. It ensures smooth feeding and stable follow-up processing such as cutting, punching, cold forming, and stamping.

Key Functions

-

Corrects metal bending and warping

-

Improves surface flatness and dimensional accuracy

-

Enhances downstream process stability

-

Reduces scrap rates and production costs

Core Parameters of Our Straightening Machine

Below is a simple parameter table for reference:

| Parameter | Specification |

|---|---|

| Material Type | Steel, Aluminum, Copper |

| Thickness Range | 0.3–6 mm |

| Straightening Speed | 15–25 m/min |

| Roller Quantity | 7–11 pcs |

| Control System | Servo/PLC automatic control |

| Application | Coil processing, stamping, automotive parts |

These configurations reflect typical models produced by Tangshan Yuexin Machinery Manufacturing Co., Ltd., supporting precision and long-term operation.

Why Is a Straightening Machine Important in Industrial Manufacturing?

A Straightening Machine enhances product consistency, reduces manual correction, and guarantees stable supply for high-accuracy manufacturing sectors such as automotive, hardware, construction, and electronics.

Benefits

-

Higher production efficiency

-

Improved accuracy in finished parts

-

Reduced labor intensity

-

Longer service life of downstream machinery

Straightening Machine Q&A

Q1: Why do I need a Straightening Machine for my production line?

A1: You need it to ensure stable feeding and accurate material flatness, minimizing defects and improving overall output quality.

Q2: What should I consider when choosing a Straightening Machine?

A2: You should consider thickness range, speed, roller quantity, and automation level—factors that directly impact straightening performance.

Q3: How can I maximize the efficiency of my Straightening Machine?

A3: I recommend regular roller cleaning, checking alignment, and using professional equipment from trusted manufacturers like Tangshan Yuexin Machinery Manufacturing Co., Ltd. I have personally seen how proper maintenance significantly increases equipment lifespan.

Working Effects and Practical Performance

A high-quality straightening system ensures:

-

Smooth material feeding

-

Even stress distribution across the metal

-

Improved forming quality

-

Reduced downtime and maintenance worries

I have witnessed how properly calibrated equipment can transform a production line, reducing errors and increasing capacity.

Importance and Application Value

Straightening equipment is vital for:

-

Metal stamping lines

-

Automotive part manufacturers

-

Machinery components

-

Construction hardware

-

Coil processing centers

Its importance lies in guaranteeing dimensional stability, improving final product quality, and supporting continuous mass production.

Why Choose Tangshan Yuexin Machinery Manufacturing Co., Ltd.?

-

Over 15 years of specialized manufacturing

-

Advanced machining and assembly facilities

-

Customizable straightening solutions

-

Reliable after-sales support and global service

We provide durable, stable, and high-accuracy systems tailored to your production needs.

If you are looking for a trusted supplier of professional straightening systems, contact us today and let our engineering team help you upgrade your production line with confidence.