What Makes an AAC Panel Machine Essential for Modern Construction?

2025-12-23

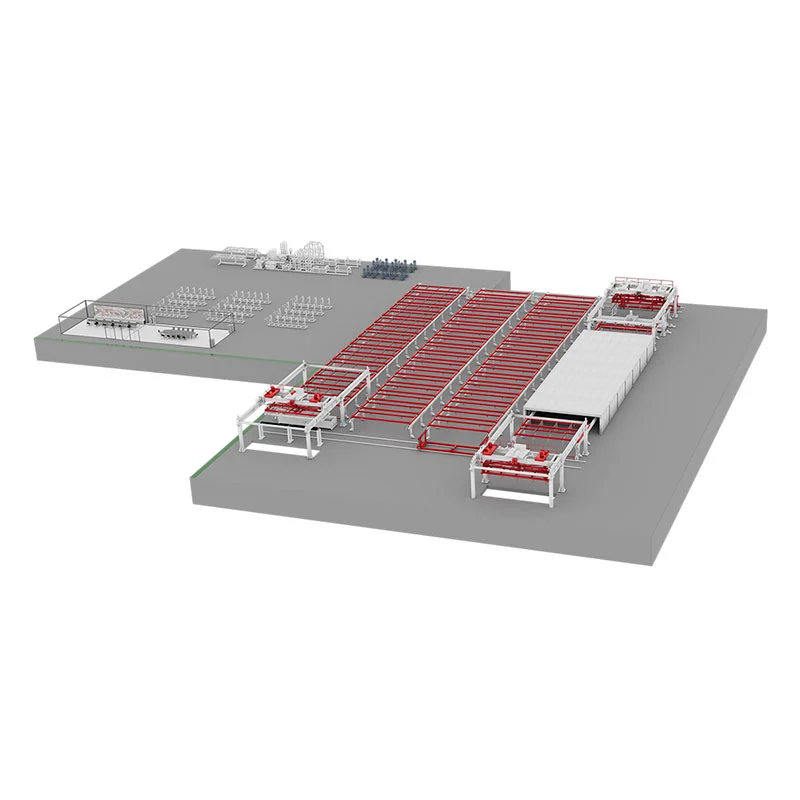

In recent years, the construction industry has been shifting towards faster, more efficient, and eco-friendly building solutions. One key innovation driving this change is the AAC Panel Machine, a high-tech system designed to produce autoclaved aerated concrete panels with precision and speed. At ZENITH Maschinenfabrik GmbH, we have seen firsthand how these machines not only improve production efficiency but also enhance the overall quality of building projects.

I often get asked: "Why should I consider investing in an AAC Panel Machine for my factory?" The answer is simple. These machines streamline the entire panel production process, from mixing raw materials to molding and curing, allowing manufacturers to produce uniform, high-quality AAC panels at scale. In my experience, companies using an AAC Panel Machine experience up to 30% faster production rates compared to traditional methods.

Key Functions and Benefits of an AAC Panel Machine

-

High Efficiency: Automates mixing, molding, cutting, and stacking, reducing manual labor.

-

Consistent Quality: Ensures uniform density and smooth surfaces for better construction outcomes.

-

Eco-Friendly Production: Low energy consumption and minimal waste production.

-

Cost-Effective: Reduces raw material usage while increasing output.

| Feature | Benefit | Impact |

|---|---|---|

| Automated Cutting System | Precise panel dimensions | Reduced human error |

| High-Speed Mixer | Consistent mixture quality | Better panel strength |

| Stacking & Curing Control | Optimal drying and curing process | Higher production efficiency |

| Energy-Efficient Motors | Low power consumption | Reduced operating costs |

Another common question I receive is: "How does an AAC Panel Machine improve construction project timelines?" I can confidently say that the machine's automated workflow drastically reduces production downtime. With panels ready in a shorter period, contractors can accelerate the assembly phase, which is especially valuable in large-scale residential and commercial projects.

Why AAC Panels Are Gaining Popularity

-

Lightweight Structure: Easier to transport and handle on construction sites.

-

Excellent Insulation: Provides superior thermal and acoustic insulation.

-

Fire Resistance: Enhances building safety standards.

-

Design Flexibility: Can be cut into various shapes and sizes.

Finally, I am often asked: "Which industries benefit most from AAC Panel Machines?" The answer is broad. From residential housing developers to commercial and industrial construction firms, any project requiring fast, precise, and sustainable building materials can leverage the advantages of AAC Panel Machines. At ZENITH Maschinenfabrik GmbH, we specialize in delivering tailored solutions for each client, ensuring machines are configured for specific production goals.

In conclusion, an AAC Panel Machine is more than just a piece of equipment; it is a strategic investment for companies aiming to boost efficiency, quality, and sustainability in construction. If you want to take your production capabilities to the next level, contact us today to explore how our AAC Panel Machines can transform your operations.