What Makes an Impact System Essential for Material Handling Efficiency?

2025-11-05

In the modern industrial landscape, optimizing the protection and longevity of conveyor belts and chutes is critical. I often ask myself, how can I ensure maximum efficiency and minimal maintenance downtime? The answer lies in a well-designed Impact System. By absorbing and dissipating the energy from falling materials, the Impact System prevents premature wear, reduces maintenance costs, and enhances operational safety. In our daily operations at Qingdao Quality Material Handling Co., Ltd., we rely on Impact Systems to maintain seamless material flow while minimizing equipment damage.

How Does an Impact System Work?

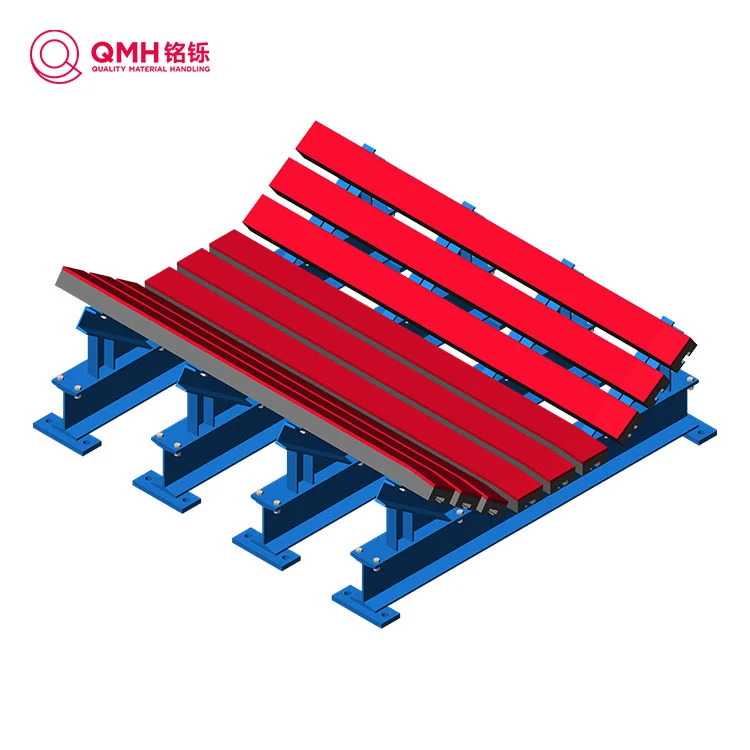

An Impact System is engineered to protect key points along conveyor systems where bulk materials, such as ores, coal, or aggregates, are transferred. These systems use impact bars or rubber blocks to cushion the impact of falling materials, ensuring the conveyor structure and belt are shielded from excessive force.

Key components include:

-

Impact Bars: Heavy-duty steel or polyurethane bars positioned at loading points.

-

Mounting Frames: Designed for stability and ease of installation.

-

Rubber Pads or Blocks: Absorb shock and prevent material spillage.

-

Adjustable Spacers: Ensure optimal alignment for varying conveyor widths.

The precise design of an Impact System ensures that energy from high-speed materials is dissipated effectively, reducing wear on both the conveyor belt and structural supports.

What Are the Main Advantages of Using an Impact System?

Investing in a high-quality Impact System offers multiple benefits, including:

| Feature | Benefit |

|---|---|

| Shock Absorption | Reduces conveyor belt damage and prolongs lifespan |

| Easy Maintenance | Modular design allows quick replacement of worn components |

| Material Flow Optimization | Minimizes spillage and keeps material moving smoothly |

| Safety Enhancement | Reduces risk of accidents caused by falling materials |

| Cost Efficiency | Lowers long-term maintenance and replacement expenses |

At Qingdao Quality Material Handling Co., Ltd., we emphasize durability and precision in our Impact Systems, ensuring that every component meets rigorous industrial standards.

How to Choose the Right Impact System for Your Application?

Selecting the right Impact System requires careful consideration of several factors:

-

Material Characteristics: Weight, abrasiveness, and size of conveyed material.

-

Conveyor Speed: Faster belts require more robust impact absorption.

-

Load Volume: High-capacity systems need multiple impact points.

-

Environmental Conditions: Temperature and exposure to chemicals or moisture affect material choice.

Our team at Qingdao Quality Material Handling Co., Ltd. provides tailored guidance to help industries select and install the most effective Impact System, ensuring minimal downtime and maximum operational efficiency.

FAQ – Impact System

Q1: What is an Impact System used for?

A1: An Impact System is designed to protect conveyor belts and transfer points from damage caused by falling bulk materials. It absorbs impact energy, reduces wear, and prevents material spillage, ensuring longer service life and smoother operation.

Q2: How do I maintain an Impact System?

A2: Regular inspection is crucial. Check for worn bars or rubber pads, ensure proper alignment, and replace components as needed. Qingdao Quality Material Handling Co., Ltd. recommends a preventive maintenance schedule to maximize efficiency and minimize downtime.

Q3: Can an Impact System handle all types of materials?

A3: Most Impact Systems are versatile, but material characteristics like weight, size, and abrasiveness determine the best design. Customized solutions are available to suit specific industrial needs, ensuring optimal protection and performance.

Why Is an Impact System a Smart Investment?

An Impact System is not just an accessory but a strategic investment for any material handling operation. By reducing wear, preventing belt misalignment, and ensuring safer material flow, it directly contributes to cost savings and operational reliability. Industries using our systems at Qingdao Quality Material Handling Co., Ltd. report noticeable reductions in maintenance frequency and equipment replacement costs.

If you are considering upgrading your conveyor protection or want a tailored Impact System solution, contact Qingdao Quality Material Handling Co., Ltd. today to explore options that meet your operational needs. Our professional team ensures high-quality design, installation, and support to keep your material handling system running efficiently.