What Makes the Monolayer Film Blowing Machine Essential for Modern Plastic Production?

2026-01-06

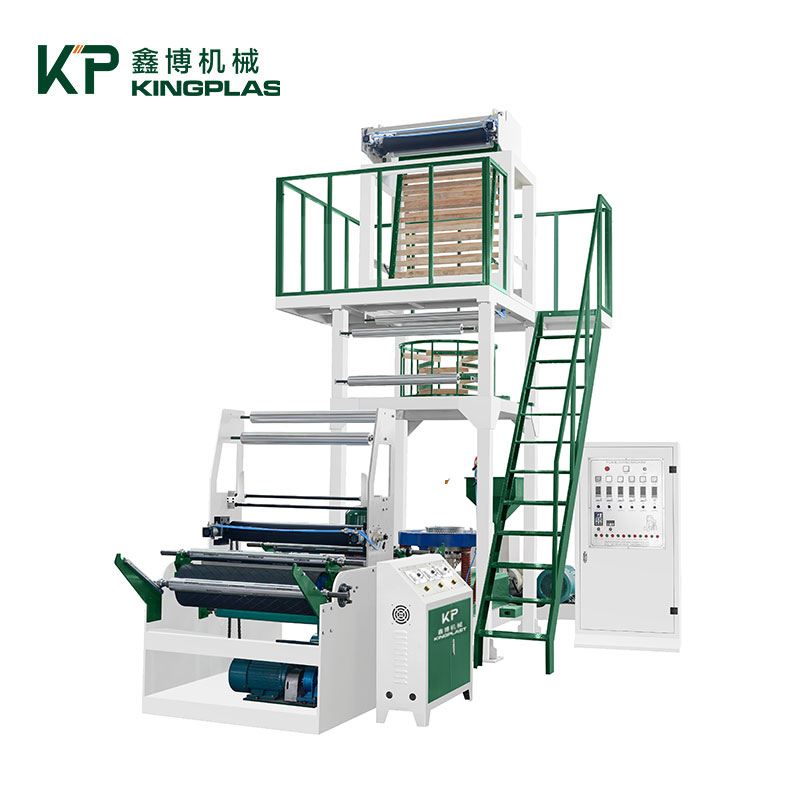

In today's competitive plastic manufacturing industry, efficiency, quality, and versatility are crucial. One machine that stands out in producing high-quality plastic films is the Monolayer Film Blowing Machine. Companies like Ruian Kingplast Machinery Co., Ltd. have optimized this equipment to meet the increasing demands for thin, durable, and uniform films. Unlike multilayer machines, monolayer systems focus on simplicity, cost-effectiveness, and flexibility, making them ideal for small to medium-scale production.

Key Features of Monolayer Film Blowing Machines

A Monolayer Film Blowing Machine offers a combination of precision, energy efficiency, and operational ease. Below is a quick overview of its core features:

| Feature | Description | Benefit |

|---|---|---|

| Single-layer extrusion | Produces uniform plastic film in one layer | Cost-effective and simple operation |

| Adjustable die | Customizable film thickness | Meets diverse product requirements |

| High-speed screw | Efficient plastic melting | Improves production output |

| PLC control system | Automatic monitoring | Reduces labor costs and errors |

| Wide application | Suitable for LDPE, HDPE, and other polymers | Versatile for various industries |

How Does It Work?

The Monolayer Film Blowing Machine operates by melting plastic pellets and extruding them through a circular die. Air is introduced into the extruded tube to form a bubble, which is then collapsed and wound into rolls. This process ensures a consistent thickness and high-quality surface, essential for packaging films, bags, and agricultural films.

Why Choose Monolayer Over Multilayer Machines?

While multilayer machines are ideal for barrier films and specialized applications, monolayer machines offer several advantages:

-

Lower cost: Fewer components reduce initial investment and maintenance expenses.

-

Simpler operation: Easier to train operators and quicker to switch production.

-

Energy efficiency: Consumes less power due to a single extrusion process.

-

High flexibility: Can handle a range of polymers and film sizes.

Typical Applications

The versatility of the Monolayer Film Blowing Machine makes it suitable for multiple industries:

-

Packaging Industry: Grocery bags, shrink films, and liners.

-

Agriculture: Mulch films and protective coverings.

-

Industrial Use: Protective films for machinery or furniture.

Benefits of Using Ruian Kingplast Machinery Co., Ltd.'s Machines

Ruian Kingplast Machinery Co., Ltd. ensures that each machine is designed with precision and durability in mind. Key benefits include:

-

Robust build quality for long-term usage.

-

High-efficiency production for lower operational costs.

-

Easy maintenance and replacement of parts.

-

Customizable models to fit unique production needs.

Conclusion

Investing in a Monolayer Film Blowing Machine is a strategic move for businesses looking to enhance film production efficiency, reduce costs, and maintain high-quality output. Whether you are producing packaging materials or agricultural films, this machine provides a reliable solution for modern manufacturing challenges.

If you are ready to improve your production line and achieve superior film quality, contact us at Ruian Kingplast Machinery Co., Ltd. today and discover the perfect monolayer solution for your business.