What Makes Tube Shrinking Machine Assembly a Solution for Precision Manufacturing?

2025-09-25

In industries where precision, consistency, and efficiency define competitiveness, Tube Shrinking Machine Assembly has emerged as a crucial solution.

The primary reason is reliability. Traditional manual shrinking or heating processes often lead to inconsistencies—uneven shrinkage, air gaps, or damage to sensitive materials. In contrast, a professionally engineered tube shrinking machine assembly ensures controlled heat distribution, uniform shrinkage, and secure bonding between materials. This means fewer defects, reduced waste, and higher production output.

Another factor is compliance with modern safety and quality standards. For example, medical tubing used in surgical equipment requires absolute precision and sterility. A tube shrinking machine assembly can be customized to operate in cleanroom environments, ensuring contamination-free processes. Similarly, in electronics, the assembly guarantees that wires and cable terminations are fully insulated, minimizing the risk of failure during long-term use.

From a cost perspective, investment in a tube shrinking machine assembly reduces operational expenses over time. Lower scrap rates, minimal human error, and faster cycle times translate into measurable ROI. In an environment where production margins are shrinking, automation like this is not just an advantage but a necessity.

Ultimately, the question “why choose tube shrinking machine assembly?” can be answered with three key points:

-

Consistency: Each component meets exact specifications.

-

Efficiency: Faster production with fewer defects.

-

Scalability: Adaptable for small-batch and high-volume manufacturing.

These advantages make the machine assembly indispensable across industries that rely on high-performance tubing systems.

What Are the Core Features and Parameters of a Tube Shrinking Machine Assembly?

Understanding what sets apart a high-quality tube shrinking machine assembly requires a closer look at its technical structure. Below is a consolidated parameter table that highlights critical specifications commonly evaluated by manufacturers:

| Parameter | Specification Range |

|---|---|

| Power Supply | AC 220V / 380V, 50Hz or customized |

| Heating Method | Infrared, hot air, or induction-based |

| Temperature Control | Adjustable, typically 50°C – 300°C with precision sensors |

| Shrinking Diameter Range | 1 mm – 50 mm (customizable for larger tubes) |

| Cycle Time | 2 – 10 seconds per tube, depending on material thickness |

| Automation Level | Semi-automatic / Fully automatic options |

| Applicable Materials | PVC, PET, PE, polyolefin, fluoropolymers |

| Safety Features | Overheating protection, emergency stop, auto shutdown |

| Productivity Output | 1000 – 5000 pieces per hour, depending on model |

| Environmental Compatibility | Cleanroom adaptation, low noise, energy-saving functions |

These specifications demonstrate how the machine assembly is designed not just for speed but also for precision. Advanced models incorporate digital control panels, allowing operators to set exact parameters for temperature and cycle time. This minimizes the variability in shrinkage and ensures compatibility with different tubing materials.

Another important aspect is adaptability. Some industries require customized nozzles or adjustable heating chambers to accommodate irregular tube sizes. A flexible assembly system can switch between different product lines quickly, making it a versatile investment.

Manufacturers also value durability. Machines with stainless steel housing, reinforced heating elements, and intelligent cooling systems have longer lifespans, reducing downtime and maintenance costs. The goal is to deliver reliable performance for years with minimal intervention.

Therefore, when considering what defines a superior tube shrinking machine assembly, the answer lies in a blend of robust engineering, customizable parameters, and precision-driven control systems.

How Does Tube Shrinking Machine Assembly Improve Manufacturing Processes?

The effectiveness of tube shrinking machine assembly can be better understood by examining how it transforms real-world production workflows. Let us explore its impact across several applications:

Electronics and Electrical Engineering

In cable harnessing and wire insulation, heat shrink tubes are essential for safety and durability. Manual application often results in uneven coverage. The machine assembly automates the process, ensuring each cable joint is sealed with perfect consistency. This prevents exposure to environmental hazards like moisture or dust and significantly extends product life.

Medical Equipment

Sterility and accuracy define medical-grade tubing. From catheters to intravenous lines, tube shrinking machine assembly delivers contamination-free, uniform results. Machines can be operated in cleanrooms, ensuring the integrity of life-saving medical devices.

Automotive Manufacturing

Vehicles rely on complex wiring and fluid transmission systems. With tube shrinking machine assembly, manufacturers achieve reliable insulation, fluid-tight seals, and long-lasting joints. This reduces warranty claims and enhances vehicle safety.

Packaging and Consumer Goods

Shrink tubes are used to bundle products or create tamper-evident seals. A shrinking machine ensures rapid, consistent packaging without damaging sensitive items inside. This application is especially important in pharmaceuticals, where consumer trust depends on product safety.

Process Efficiency

So how exactly does the machine improve efficiency? It achieves this through:

-

Reduced Labor: Automation decreases dependency on manual workers.

-

Faster Turnaround: High-speed shrinking ensures quick delivery schedules.

-

Error Elimination: Precise digital controls reduce costly rework.

-

Energy Savings: Intelligent heating elements lower power consumption.

In other words, tube shrinking machine assembly answers the “how” question by demonstrating its ability to merge speed, quality, and cost-effectiveness into one streamlined system.

Future Outlook and Why Choose Feihong for Tube Shrinking Machine Assembly

As industries move toward smart manufacturing and Industry 4.0 integration, tube shrinking machine assemblies are evolving too. Features like IoT connectivity, predictive maintenance alerts, and AI-based monitoring are gradually being introduced, enabling operators to achieve unprecedented levels of precision and productivity. The future points toward greater automation and sustainability, with machines designed to use less energy and produce minimal waste.

But beyond technology, the choice of supplier plays a pivotal role. Why should businesses trust a specific brand for such a critical piece of equipment? The answer lies in proven expertise, product reliability, and after-sales support.

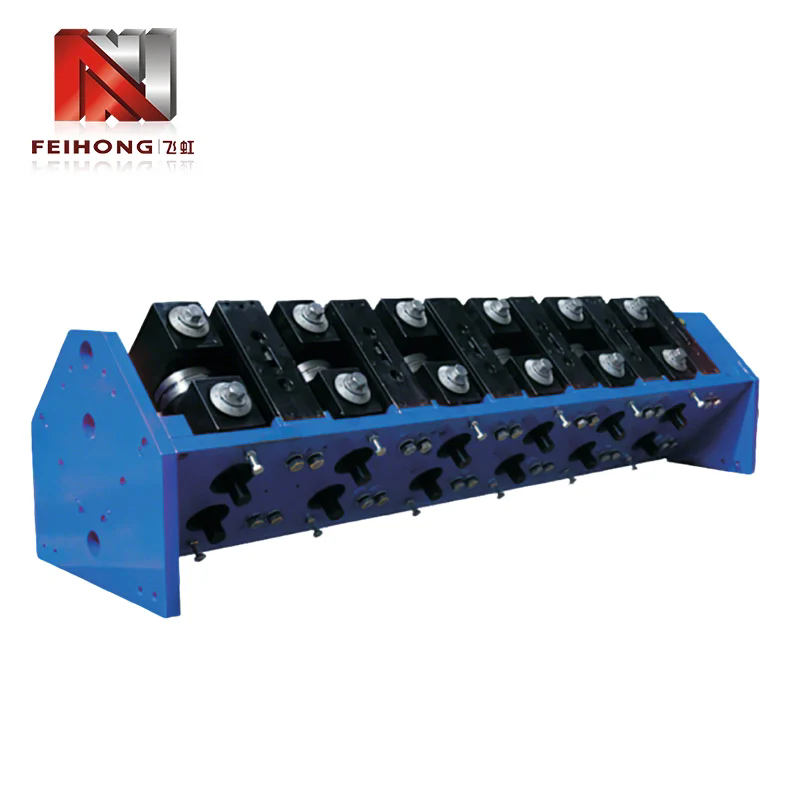

Feihong has consistently delivered high-performance tube shrinking machine assemblies tailored to diverse industries. With a focus on engineering excellence and customer-driven innovation, Feihong machines are designed to perform in demanding environments while maintaining superior quality standards. Clients worldwide recognize the brand for durability, customization options, and responsive technical support.

For companies seeking to upgrade their production lines, the question is not whether to adopt tube shrinking machine assembly, but which partner to trust. With Feihong’s expertise and commitment to customer success, manufacturers can confidently embrace efficiency, precision, and long-term reliability.

Contact us today to learn how Feihong can help your business achieve seamless tube shrinking solutions with maximum performance and minimal downtime.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from tube shrinking machine assembly?

A1: Industries such as electronics, automotive, medical devices, and packaging benefit significantly due to their need for precision, insulation, and secure sealing.

Q2: How does tube shrinking machine assembly ensure quality consistency?

A2: By using advanced temperature control systems and automated processes, it ensures every tube shrinks uniformly, reducing defects and rework.

Q3: Why is investing in tube shrinking machine assembly cost-effective?

A3: It reduces manual labor, speeds up production, minimizes errors, and extends product lifespan—leading to lower operational costs over time.