What Raw Materials Are Used in a Steel Reinforced Pipe Machine

2025-12-11

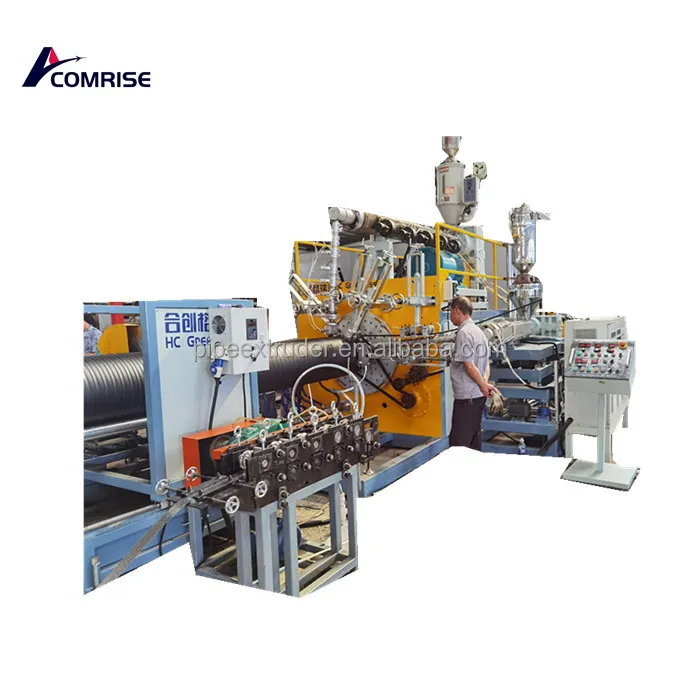

Understanding the raw materials is crucial for anyone investing in a Steel Reinforced Pipe Machine. The quality of the final pipe is directly tied to the inputs. At Comrise, we engineer our high-performance machines to process premium materials efficiently, ensuring superior end-products for irrigation, drainage, and construction. This blog breaks down the essential raw materials and how our Comrise machines are optimized to handle them.

The primary materials are the steel wire/mesh and the polymer compound. Their specifications determine the pipe's strength, flexibility, and durability.

Core Raw Material Components:

-

High-Tensile Steel Reinforcement:

-

Type: Galvanized or stainless steel wire/helical mesh.

-

Function: Provides structural hoop strength and pressure resistance.

-

Key Spec: Tensile strength (typically 550-1450 MPa) and zinc coating weight for corrosion resistance.

-

-

Polymer Compound Matrix:

-

Base Resin: Primarily HDPE (High-Density Polyethylene) or LDPE (Low-Density Polyethylene), chosen for chemical resistance and flexibility.

-

Additives: UV stabilizers, carbon black (for weathering resistance), and processing aids to ensure smooth extrusion and material fusion.

-

Our Comrise Steel Reinforced Pipe Machine is precisely calibrated for these materials. Here are key Comrise parameters that guarantee consistent processing:

| Comrise Machine Parameter | Function & Material Impact |

|---|---|

| Preheating System for Wire | Ensures optimal temperature for perfect polymer-steel adhesion, preventing delamination. |

| Precision Crosshead Die | Coordinates the exact merging of molten polymer and steel reinforcement into a cohesive structure. |

| Advanced PLC Control | Maintains strict tolerances on extrusion temperature, pull speed, and cooling, critical for material integrity. |

Steel Reinforced Pipe Machine FAQ

Q: Can the machine use recycled polymer materials?

A: Yes, but with caution. Comrise machines can process certain percentages of high-quality recycled HDPE compound. However, using too much or inconsistent recycled material can affect pressure rating and long-term stability. We recommend consulting our engineers for an optimal virgin/recycled blend ratio.

Q: What steel wire diameter can your machine accommodate?

A: Our Steel Reinforced Pipe Machine models are versatile. Standard configurations handle wire diameters from 0.8mm to 2.5mm. Customization is available for specific reinforcement needs, allowing you to produce pipes for different pressure classes (e.g., PN4, PN6, PN10).

Q: How does material quality affect machine performance and output?

A: Directly and significantly. Inferior or inconsistent raw materials cause production issues like wire slippage, poor extrusion coating, and increased scrap rates. High-quality, stable materials ensure our Comrise machine runs at peak efficiency, maximizing output speed (meters/hour) and producing uniform, reliable pipes with minimal downtime.

Ready to produce top-quality reinforced pipes with optimal material efficiency? Contact Comrise today. Our experts will help you configure the perfect Steel Reinforced Pipe Machine for your raw material specifications and production goals.