What Size and Thickness of Pallets Are Best for Standard Concrete Blocks

2025-12-05

Choosing the right Block Machine Pallet is a critical decision that directly impacts the efficiency, quality, and longevity of your block production line. For manufacturers producing standard concrete blocks, such as hollow or solid blocks, selecting the optimal pallet specifications ensures smooth operation, minimal downtime, and consistent product quality. At Quangong Machinery, we specialize in engineering durable, high-performance pallets tailored to meet the rigorous demands of modern block plants. This guide will help you determine the best size and thickness for your standard block production.

For standard concrete blocks (typically 8x8x16 inches or similar metric dimensions), the pallet size must accommodate the block mold and allow for safe handling and stacking. The most common and recommended Block Machine Pallet sizes are:

-

880mm x 480mm (Approx. 34.6" x 18.9"): Ideal for producing a single row of standard blocks.

-

1200mm x 600mm (Approx. 47.2" x 23.6"): Suitable for producing multiple blocks in a matrix layout, optimizing output per cycle.

Thickness is equally crucial, as it determines the pallet’s ability to withstand repeated stress, vibration, and weight without warping. The industry standard recommendations are:

| Block Type | Recommended Pallet Thickness | Key Reason |

|---|---|---|

| Standard Hollow/Solid Blocks | 6mm to 8mm Steel Plate | Provides the perfect balance of durability, weight, and resistance to deformation under high-frequency vibration. |

| High-Volume Production | 8mm to 10mm Steel Plate | Offers enhanced longevity and minimal deflection for 24/7 operations, reducing long-term replacement costs. |

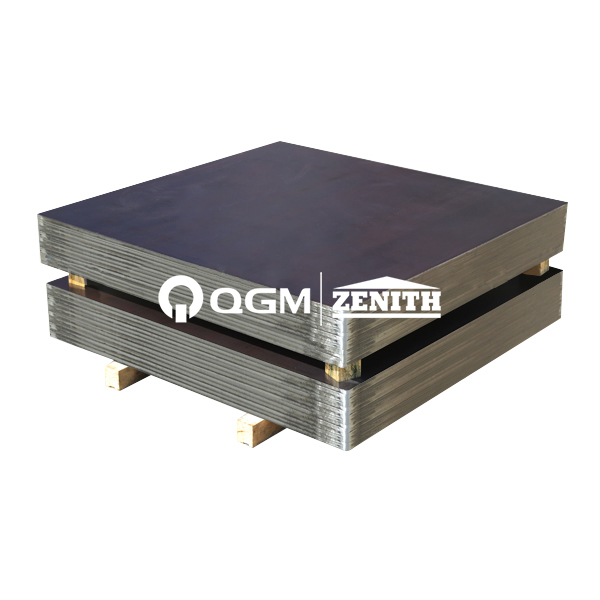

Quangong Machinery pallets are precision-manufactured from high-carbon, wear-resistant steel (Q235 or equivalent grade). Our standard Block Machine Pallet features include hardened surfaces, reinforced edges, and precisely machined dimensions for seamless integration with all major block machine brands, ensuring flawless demolding and transportation.

Block Machine Pallet FAQ

Q: Can I use a thicker pallet than recommended for even longer life?

A: While thicker pallets (e.g., 12mm) offer extreme durability, they are significantly heavier. This increases energy consumption for the conveyor system, adds wear to rollers and elevators, and may reduce the speed of your pallet return circuit. Quangong Machinery advises that the 6-10mm range is the most cost-effective and operationally efficient for standard blocks.

Q: How does pallet size affect my plant's layout and output?

A: The pallet size dictates the footprint of your curing racks, stackers, and the overall flow design. A larger 1200x600mm pallet produces more blocks per cycle but requires wider conveyors and more space. Our experts at Quangong Machinery can help you model your production line to choose the size that maximizes your space and output goals.

Q: What maintenance do steel pallets require?

A: Regular maintenance is minimal but essential. It primarily involves inspecting for material build-up and cleaning the surface to ensure a smooth finish for easy block release. Quangong Machinery pallets are treated with anti-rust coatings, but storing them in a dry area when not in prolonged use will further extend their service life significantly.

Selecting the correct Block Machine Pallet is an investment in your plant's productivity. By partnering with Quangong Machinery, you gain access to expertly engineered pallets built to exact specifications, backed by decades of industry knowledge.

Contact us today for a free consultation! Let our team analyze your production needs and recommend the perfect pallet size, thickness, and configuration to optimize your block-making operation.