Which Auxiliary Machines Are Essential For Concrete Brick Making

2025-10-20

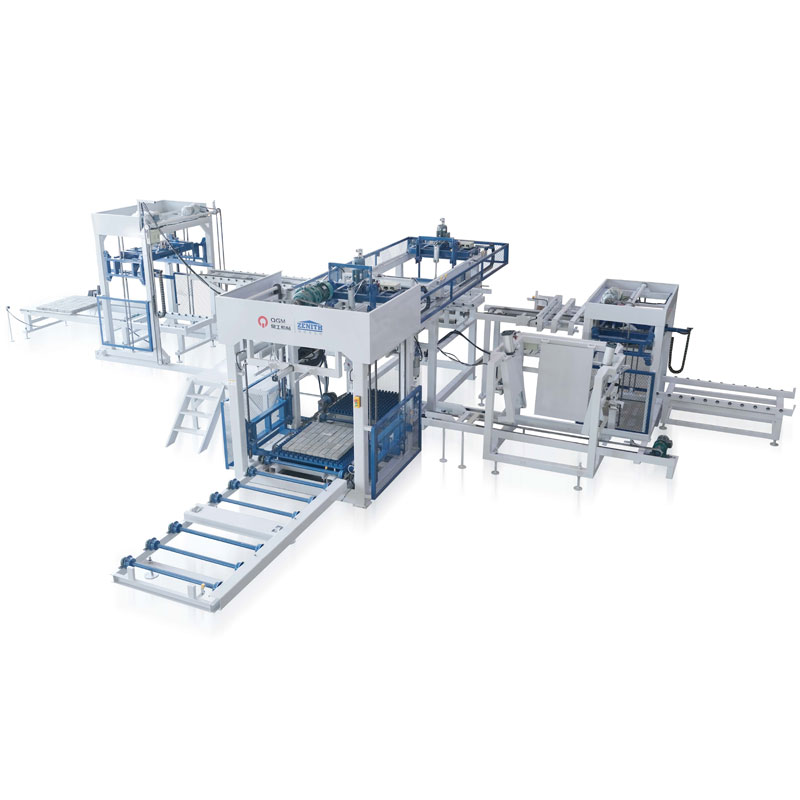

Building a profitable concrete brick production line involves more than just the primary block machine. Having visited hundreds of plants worldwide, I've seen that the most successful operations invest in a complete ecosystem of Auxiliary Brick Machinery. These machines are not optional extras; they are fundamental to achieving high output, consistent quality, and low operational costs. For any manufacturer serious about competing in today's market, understanding and integrating these key pieces of Auxiliary Brick Machinery from QGM is the definitive step towards automation and efficiency.

What Are The Core Components Of An Integrated System

A seamless workflow is impossible without the right supporting equipment. The essential Auxiliary Brick Machinery units work in concert to handle material preparation, product handling, and curing.

-

Automatic Batching and Mixing System: This is the foundation of quality control. A QGM automated system precisely weighs cement, aggregates, and water, ensuring every mix batch has the perfect consistency for superior brick strength and dimensional accuracy.

-

Automatic Brick Stacker: Handling green bricks manually is a primary source of damage and labor cost. An automatic stacker gently collects bricks from the production pallet and forms perfect, stable stacks for curing, drastically reducing product loss.

-

Curing System: Proper curing is a science. QGM offers integrated curing solutions that control temperature and humidity, ensuring your bricks achieve their designed compressive strength and durability efficiently and consistently.

The synergy between these machines is critical. The specifications of your Auxiliary Brick Machinery must be perfectly matched to your primary press's output.

| Machine Type | Core Function | QGM Model Specification |

|---|---|---|

| Automatic Batching System | Precise raw material proportioning | 4 m³ batch capacity, ±0.5% weighing accuracy |

| Automatic Brick Stacker | Gentle robotic handling of green bricks | 15-second cycle time, 6-layer stacking pattern |

| Pallet Feeder & Return System | Automated pallet circulation | 800mm width, synchronized with press cycle |

Your Auxiliary Brick Machinery FAQ

Can I add this machinery to my existing production line

Absolutely. QGM specializes in retrofitting our Auxiliary Brick Machinery into existing setups. Our engineers conduct a site audit to ensure seamless integration with your current brick machine, boosting your plant's productivity without a full replacement.

What is the biggest ROI from this equipment

The fastest return typically comes from the combined effect of labor reduction and a dramatic drop in product breakage. By automating the most delicate handling stages, you save on wages and turn waste into saleable product, often yielding an ROI within 12-18 months.

How important is the control system

It is the most critical component. A unified PLC control system, like the one QGM provides, is the brain that synchronizes all the machinery. It ensures the batcher, mixer, press, and stacker work as one cohesive unit, maximizing uptime and providing valuable production data.

Investing in the right Auxiliary Brick Machinery is the smartest decision a concrete brick manufacturer can make. It transforms a labor-intensive operation into a smooth, automated, and highly profitable plant.

Ready to optimize your brick production line Contact QGM today to get a free, customized plan for the essential Auxiliary Brick Machinery that will drive your business forward.