Which Block Making Machine Is Best for Hollow Blocks and Pavers

2025-09-16

Choosing the right Block Making Machine for producing both hollow blocks and pavers can significantly impact your project’s efficiency and output quality. Not all machines offer the versatility and durability needed to handle different block types without compromising performance. So, what should you look for?

Key features to consider include:

-

High-pressure compression for dense, durable blocks

-

Quick mold change system to switch between products seamlessly

-

Automated production process to reduce labor and increase output

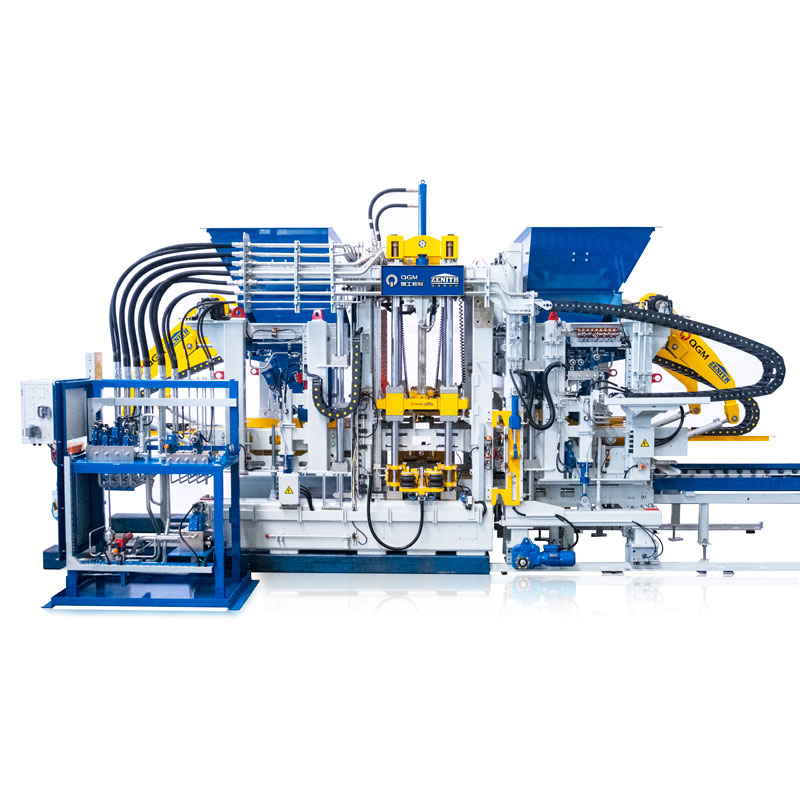

At QGM, we engineer our machines to excel in these areas. Our Block Making Machine models are designed with flexibility in mind, allowing the same equipment to produce hollow blocks, pavers, kerbstones, and more—all with minimal downtime between batches.

Here’s a technical overview of our mid-range model suited for hollow blocks and pavers:

| Feature | Specification |

|---|---|

| Production Capacity | Up to 36,000 blocks per 8-hour shift |

| Standard Block Cycle Time | 15–20 seconds |

| Max Compression Force | 3,200 kN |

| Power Requirements | 45 kW |

| Automation Level | Fully automatic with PLC control |

This machine ensures consistent quality and high output whether you’re producing hollow blocks for construction or decorative pavers for landscaping.

Frequently Asked Questions

What is the average production output for a fully automatic Block Making Machine

A fully automatic machine can produce between 30,000 to 40,000 standard blocks in an 8-hour shift depending on model and configuration. Machines from QGM are optimized for high output with minimal manual intervention.

Can the same machine produce both hollow blocks and pavers

Yes. With a quick mold change system like the one offered in QGM machines, operators can switch production from hollow blocks to pavers in under 30 minutes without needing extra equipment.

What type of maintenance does a block production machine require

Regular maintenance includes daily checking of hydraulic oil levels, cleaning the vibration system, and inspecting mold integrity. QGM machines are built with easily accessible parts to simplify upkeep and reduce downtime.

If you’re looking for a machine that delivers versatility, reliability, and high performance for both hollow blocks and pavers, QGM offers solutions trusted worldwide.

Contact us today to discuss your requirements and receive a customized recommendation tailored to your production goals. Let QGM help you build better.