Why Are Double-Side Machines Transforming Precision Manufacturing Today?

2025-11-28

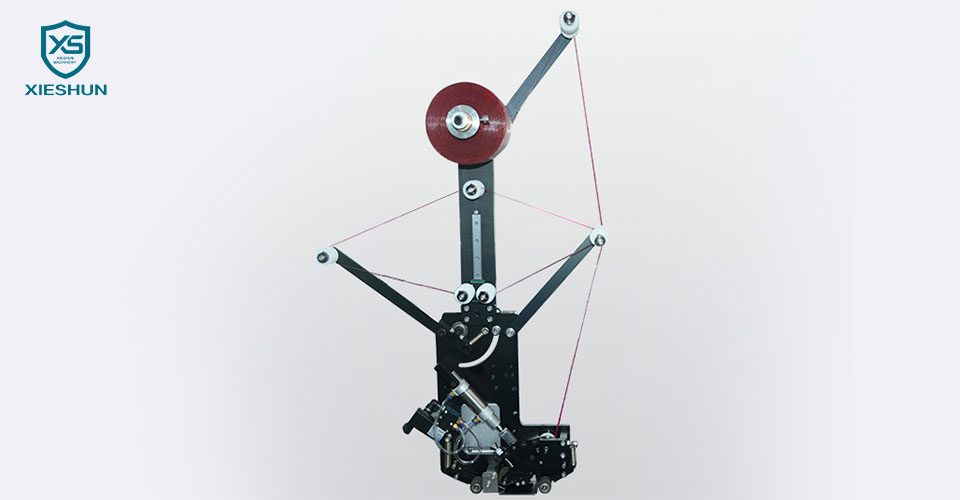

A Double-Side Machine is a high-precision manufacturing system designed to process two parallel surfaces of a workpiece simultaneously. By applying controlled pressure, synchronized motion, and matched abrasive or polishing plates on both sides, it achieves exceptional flatness, thickness accuracy, and surface finish. This dual-action approach dramatically increases efficiency compared with single-side processing, making it a core technology in industries requiring consistent surface quality—such as aerospace, automotive, semiconductors, optics, ceramics, and advanced materials engineering.

Product Parameters — What Technical Features Define a High-Performance Double-Side Machine?

Professionals evaluating Double-Side Machines require measurable specifications to compare performance. The following table outlines key parameters typically demanded for quality-critical applications:

| Parameter | Specification Range | Technical Description |

|---|---|---|

| Working Diameter | 610 mm – 1500 mm | Determines maximum part size and batch capacity. |

| Plate Material | Cast iron / Ceramic / Composite | Selected based on material hardness and desired finishing accuracy. |

| Flatness Tolerance | Within 1–2 μm | Ensures two-sided uniformity for optical-grade components. |

| Parallelism Accuracy | ≤ 1 μm | Achieves precise thickness consistency across batches. |

| Material Compatibility | Metal, ceramic, glass, silicon, sapphire, PCB, carbon materials | Enables versatile application across multiple industries. |

| Working Pressure | Adjustable 20–250 kg per carrier | Supports controlled removal rates and stable processing. |

| Spindle Speed | 10–90 rpm variable | Optimizes cutting, lapping, or polishing performance. |

| Automation Level | Manual / Semi-automatic / Fully automatic | Based on production demand and workforce planning. |

| Cooling & Filtration System | Multi-stage circulation | Maintains abrasive purity for consistent results. |

| Control System | PLC + Touchscreen HMI | Provides recipe storage, intelligent adjustment, and alarm functions. |

These specifications reflect the advanced engineering that allows modern Double-Side Machines to deliver speed, accuracy, and long-term operational stability.

What Core Advantages Make Double-Side Machines Superior to Single-Side Processing?

1. Simultaneous Dual-Surface Processing

Processing both surfaces at the same time eliminates multiple steps and overturning operations. This reduces cycle time by up to 50% and increases productivity without sacrificing accuracy.

2. Improved Flatness and Parallelism

Because both sides are processed under uniform pressure within a rigid structure, the machine produces exceptional geometric consistency—critical for products such as ceramic wafers, optical lenses, mechanical seals, automotive components, and carbon plates.

3. Superior Surface Quality

The controlled lapping or polishing action minimizes micro-defects, reduces stress deformation, and supports ultra-fine finishing. This is essential for components used in high-precision environments such as sensors, microelectronics, medical devices, and aerospace assemblies.

4. Stable and Repeatable Performance

Modern Double-Side Machines integrate digital controls, servo-adjusted pressure systems, and intelligent monitoring. This ensures each batch meets the same specifications with minimal deviation, promoting continuous mass production.

5. Wide Material Compatibility

The technology easily adapts to hard, brittle, or delicate materials. By adjusting the abrasive type, plate texture, pressure distribution, and rotational speed, the machine handles metals, ceramics, glass, silicon, sapphire, composite plates, and more.

Why Do Key Industries Depend on Double-Side Machines for Critical Components?

1. Semiconductor and Electronics Manufacturing

In microelectronics, thickness accuracy and flatness determine electrical performance. Double-Side Machines prepare silicon wafers, ceramic substrates, and insulating components with tight tolerances suitable for advanced circuit integration.

2. Automotive and Mechanical Engineering

Automotive parts such as gears, pump plates, clutch plates, and hydraulic components require controlled wear resistance and dimensional uniformity. Double-Side Machines ensure perfect parallelism for smooth assembly and long-term mechanical stability.

3. Optics and Photonics

Optical lenses, filters, mirrors, and crystal components demand spotless finishes. Dual-side polishing avoids thermal distortion and produces optical-grade surfaces that enhance transmission and reflection functions.

4. Advanced Ceramics and Technical Materials

As industries adopt ceramics for high-temperature and high-pressure environments, Double-Side Machines provide the fine finishing required for turbine blades, insulating plates, armor ceramics, and ballistic materials.

5. Clean Energy and Environmental Equipment

Fuel cell plates, solar components, and carbon materials rely on consistent thickness and flatness for energy conversion efficiency. Double-Side Machines deliver high uniformity across large production batches.

How Do Double-Side Machines Operate to Achieve Micro-Level Precision?

1. Dual Rotating Plates

The upper and lower plates rotate in coordinated motion, applying matched pressure to the workpieces held inside carriers. This ensures balanced removal across both surfaces.

2. Abrasive Distribution System

A controlled slurry or fixed-abrasive film ensures consistent particle density and uniform cutting. The filtration system recycles abrasives while removing contaminants.

3. Intelligent Pressure Control

Adjustable pneumatic or servo-driven pressure systems allow users to fine-tune material removal rates based on hardness, thickness, and finishing requirements.

4. Precision Gear Mechanism

The planetary gear system guides the carriers in a synchronized orbit, ensuring uniform contact across all workpieces during the lapping or polishing process.

5. Digital Control Platform

A sophisticated control interface allows operators to store process recipes, monitor spindle speed, adjust rotational patterns, and track performance in real time.

What Future Trends Are Shaping the Development of Double-Side Machines?

1. Full Automation and Smart Manufacturing

AI-free but intelligent systems—such as automatic loading, real-time pressure balancing, and smart lubrication—enable factories to reduce labor and enhance reliability.

2. Ultra-Precision Technology

As industries demand nano-level surface finishes, machines will integrate higher-resolution sensors, more stable frames, and advanced filtration for ultra-clean processing.

3. Eco-Friendly Abrasives and Low-Consumption Systems

Sustainability initiatives are accelerating the adoption of low-waste consumables, biodegradable abrasives, and energy-optimized motor systems.

4. Customization for Industry-Specific Needs

Manufacturers increasingly require customized plate designs, pressure algorithms, and automation modules tailored to unique materials or product geometries.

5. Integration with Digital Factory Platforms

Future Double-Side Machines will connect seamlessly with MES, ERP, and quality-tracking systems to support predictive maintenance and traceable production.

Common Questions About Double-Side Machines

Q1: What materials are most suitable for Double-Side Machine processing?

A1: Double-Side Machines are compatible with a wide range of materials, including carbon steel, stainless steel, ceramics, silicon wafers, glass, sapphire, aluminum, carbon plates, and composite substrates. Because the process uses uniform pressure and balanced rotation, it is ideal for both hard and brittle materials requiring high flatness and parallelism.

Q2: How long does it take to process a batch of parts on a Double-Side Machine?

A2: Processing time varies by material hardness, removal thickness, abrasive type, and surface finish requirements. Typical cycles range from several minutes for metal components to more than thirty minutes for advanced ceramics or optical materials. The machine’s simultaneous processing of both surfaces significantly reduces total cycle time compared with single-side methods.

Why Industries Choose Professional Double-Side Machine Manufacturers

Double-Side Machines continue to reshape global manufacturing by delivering unmatched efficiency, surface accuracy, and industrial adaptability. Their expanding role in semiconductors, optics, automotive engineering, new energy, and advanced materials proves their importance as a cornerstone of precision production. As technological development pushes industries toward greater precision, automation, and sustainability, demand for highly engineered Double-Side Machines will continue to grow.

For companies seeking reliable machinery with stable performance, durable structures, and high-precision engineering, WENZHOU XIESHUN MECHANICAL EQUIPMENT CO., LTD provides advanced Double-Side Machine solutions tailored to diverse industrial requirements.

For more information or customized consultation, contact us to receive professional support and technical guidance.