Why Are Motor Shafts the Core of Modern Mechanical Systems

2025-10-17

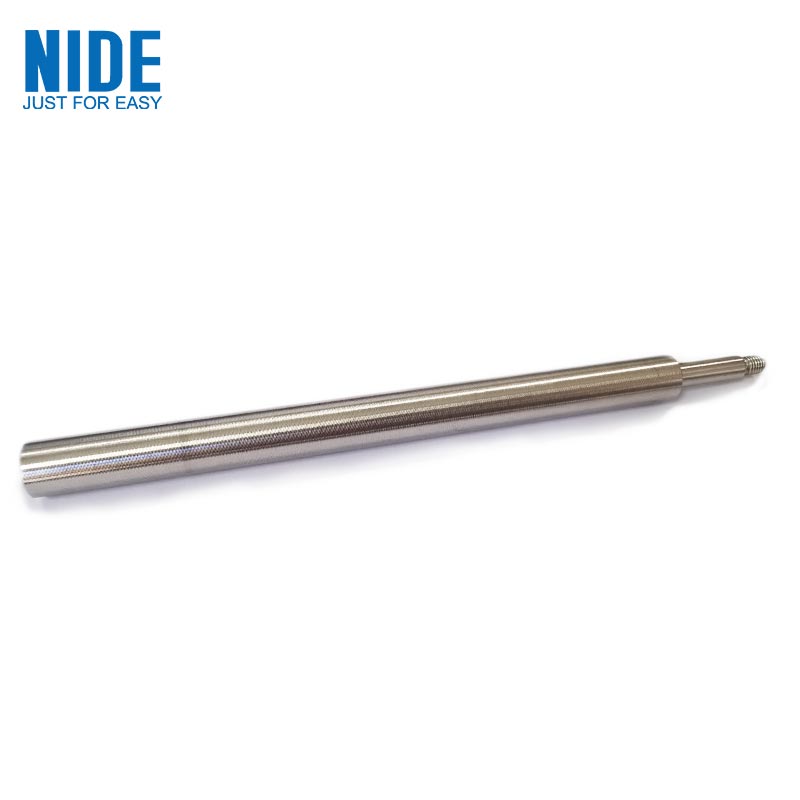

A motor shaft is one of the most crucial mechanical components in any motion-driven system. It serves as the central axis that transfers rotational motion and torque from a motor to connected parts such as gears, pulleys, propellers, or pumps. In industrial engineering, automotive design, and robotics, the shaft’s precision and durability directly determine the efficiency, stability, and lifespan of the entire machine.

What Are the Key Features and Technical Parameters of a Motor Shaft?

The performance of a motor shaft depends on its material composition, dimensional precision, surface finish, and balance tolerance. Below is a professional overview of common parameters that define a high-quality motor shaft:

| Parameter | Description | Typical Range / Material | Function |

|---|---|---|---|

| Material | Determines strength, hardness, and corrosion resistance | Carbon Steel (C45), Stainless Steel (SUS304/316), Alloy Steel | Ensures load capacity and durability |

| Diameter | Defines torque transmission capacity | 4mm – 120mm | Matches motor type and load requirements |

| Length | Customizable according to application | 20mm – 800mm | Connects motor with end components |

| Tolerance | Measures dimensional precision | ±0.005mm – ±0.02mm | Maintains smooth rotation and alignment |

| Surface Finish | Affects friction, noise, and lifespan | Ra 0.2μm – 0.8μm | Reduces wear and improves performance |

| Heat Treatment | Enhances hardness and fatigue strength | Induction Hardened / Nitrided | Extends operational life |

| Balancing | Ensures vibration-free operation | ISO G6.3 or better | Increases stability and reliability |

A well-engineered motor shaft should maintain tight concentricity, consistent torque transmission, and minimal vibration even under heavy load. The choice of material and surface treatment depends on environmental conditions such as humidity, temperature, and exposure to chemicals.

For instance, stainless steel shafts are ideal for environments where corrosion resistance is critical, while alloy steel shafts are preferred for heavy-duty or high-torque applications.

Why Is the Motor Shaft a Key Component in Performance Optimization?

Precision and Efficiency

Motor shafts act as the backbone of rotating systems. Even a microscopic misalignment can result in imbalance, vibration, and noise, leading to energy loss. High-precision manufacturing ensures smoother torque transfer, higher motor efficiency, and reduced wear on connected components.

Material Engineering and Durability

The choice of material directly impacts the strength-to-weight ratio and thermal stability. Modern manufacturers employ cold-drawn steel, precision-ground shafts, and multi-layer surface coatings to achieve longer service life and better resistance to fatigue.

Customization and Application Versatility

Motor shafts are now produced in customized configurations — such as hollow shafts, keyed shafts, splined shafts, and threaded ends — to match specific industrial uses. For example:

-

Electric Vehicle Motors: Lightweight yet high-torque-resistant shafts enhance acceleration and energy efficiency.

-

HVAC Compressors: Corrosion-resistant stainless steel shafts ensure stable operation in humid conditions.

-

Robotics and Automation: Precision-balanced shafts minimize vibration, ensuring accurate motion control.

Noise Reduction and Smooth Operation

Vibration and acoustic noise are major challenges in electric drive systems. Through precision grinding and dynamic balancing, modern motor shafts achieve low-noise, stable rotation that aligns with global standards for mechanical efficiency and comfort.

Sustainability and Future Manufacturing Trends

Environmental awareness is reshaping the future of motor shaft manufacturing. There is an increasing focus on eco-friendly materials, energy-efficient machining, and recyclable alloys. Advanced processes such as CNC turning, robotic polishing, and AI-based quality control contribute to higher consistency and less waste.

The next generation of motor shafts is expected to integrate smart monitoring systems, enabling predictive maintenance through vibration sensors and temperature tracking — allowing manufacturers to prevent mechanical failure before it happens.

How Are Motor Shafts Manufactured and What Innovations Are Driving the Industry?

The production process of a motor shaft involves multiple precision steps that determine its performance and longevity.

Manufacturing Process Overview

-

Material Selection: Choosing the right alloy based on mechanical load and environmental conditions.

-

Cutting and Rough Turning: Shaping raw material to approximate size while maintaining concentricity.

-

Heat Treatment: Increasing surface hardness through induction or nitriding.

-

Precision Grinding: Achieving accurate diameter and surface roughness.

-

Balancing and Inspection: Ensuring uniform mass distribution and zero eccentricity.

-

Surface Coating / Plating: Applying protective layers such as chrome, nickel, or black oxide.

Each stage is conducted under ISO-certified quality systems, ensuring that shafts meet both domestic and international mechanical standards.

Technological Advancements

-

CNC Micro-Grinding: Enables precision up to 0.001mm for advanced automation systems.

-

Laser Hardening: Improves wear resistance without affecting core toughness.

-

3D Quality Mapping: Detects defects at the micron level.

-

Automated Balancing Systems: Minimize human error and improve batch uniformity.

Industry Applications and Market Outlook

The motor shaft industry is expanding rapidly across electric mobility, renewable energy systems, and industrial automation. With the rise of EV powertrains, AI-driven robotics, and next-generation turbines, demand for lightweight, high-torque shafts is expected to increase exponentially.

Global manufacturers are now focusing on sustainability, precision engineering, and modular production, ensuring compatibility with multiple drive systems while reducing energy consumption during manufacturing.

Frequently Asked Questions (FAQ)

Q1: How can one determine if a motor shaft is properly balanced?

A well-balanced motor shaft shows no excessive vibration or noise during operation. Engineers typically use dynamic balancing equipment that measures vibration amplitude and phase. If imbalance exists, small corrective weights are added to counter the uneven mass distribution. Maintaining balance ensures smoother rotation, longer bearing life, and reduced energy loss.

Q2: What are the common causes of motor shaft failure and how can they be prevented?

Shaft failure often results from misalignment, overload, insufficient lubrication, or fatigue cracking. Preventive measures include:

-

Regular inspection for surface cracks or corrosion.

-

Ensuring precise motor alignment during installation.

-

Using high-quality lubricants for bearings.

-

Selecting appropriate material hardness for load conditions.

Timely maintenance and high-precision manufacturing can significantly extend the operational life of a motor shaft.

The Future of Motor Shaft Engineering and Industrial Reliability

As industries transition toward automation, electrification, and sustainability, motor shafts remain at the core of motion technology. Continuous innovation in materials science, surface treatment, and digital monitoring is driving this evolution. Manufacturers are investing heavily in research to develop hybrid composite shafts that combine steel strength with carbon-fiber lightness, offering both high torque and low inertia.

Future designs will integrate smart sensors for condition monitoring, predictive maintenance, and real-time performance optimization. These intelligent shafts will communicate with control systems, allowing engineers to prevent failures before they occur and to maximize system uptime.

The journey of the motor shaft — from raw steel to a precision-balanced mechanical axis — exemplifies the ongoing commitment to efficiency, reliability, and innovation in modern engineering.

At Sinoah, the focus is on delivering precision-engineered motor shafts designed to meet the demanding standards of global industries. Each product undergoes strict quality inspection and material testing to ensure consistent performance under all operating conditions.

For technical consultations, customization requests, or detailed quotations, contact us today to learn how Sinoah’s motor shaft solutions can optimize your mechanical systems and support your long-term success.