Why Industrial Operators Choose a Worm Screw Jack for Precision Lifting?

2025-09-12

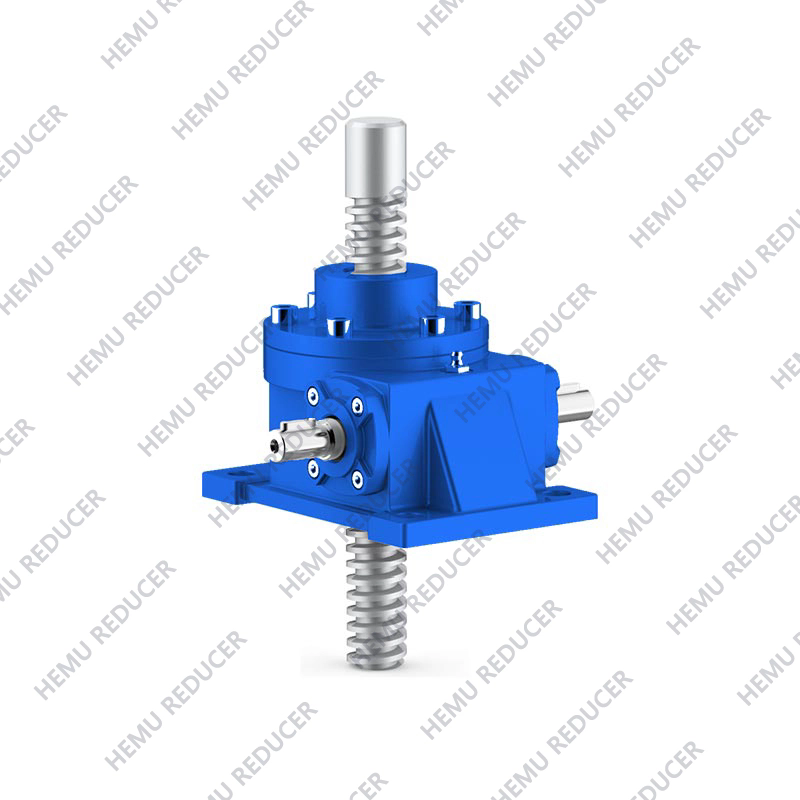

A Worm Screw Jack is a mechanical device designed to lift, lower, or precisely position heavy loads with minimal effort. Unlike conventional lifting systems, worm screw jacks employ a worm gear mechanism, which provides exceptional torque multiplication, load holding capability, and compact design. These attributes make worm screw jacks indispensable in industrial automation, material handling, construction, and engineering applications.

The operation principle is simple yet highly effective. A worm rotates along its axis, engaging with a helical gear (the worm wheel). As the worm turns, it drives the worm wheel, converting rotational motion into linear movement, which lifts or lowers the attached load. The design allows for high mechanical advantage, meaning a relatively small input force can control significantly heavier loads safely.

Key functional advantages include:

-

Self-locking mechanism: prevents back-driving, ensuring safety.

-

Smooth and precise load adjustment: ideal for applications requiring fine positioning.

-

Compact footprint: enables integration into constrained spaces.

-

High load capacity: suitable for industrial-scale lifting operations.

This mechanical efficiency makes worm screw jacks preferred in industries where precision, reliability, and safety are crucial. Unlike hydraulic or pneumatic systems, worm screw jacks require minimal maintenance, are energy-efficient, and can operate under challenging environmental conditions.

Why Choose a Worm Screw Jack Over Other Lifting Solutions?

When selecting a lifting or positioning solution, engineers and operators face multiple options, such as hydraulic cylinders, electric actuators, or chain hoists. However, worm screw jacks offer unique benefits that distinguish them from these alternatives:

-

Precision and Control: The self-locking worm gear design ensures that the load does not unintentionally move, even if power is lost or input torque stops. This makes them ideal for applications like assembly lines, stage platforms, or heavy-duty conveyor systems.

-

Durability and Low Maintenance: Built with high-grade alloy steel and corrosion-resistant coatings, worm screw jacks can withstand harsh environments, including industrial plants, outdoor lifting systems, and marine applications. The lubrication of worm gears reduces friction and wear, extending service life.

-

Compact and Versatile Design: Unlike bulky hydraulic lifts, worm screw jacks are lightweight relative to their load capacity and can be installed in tight spaces, vertically or horizontally.

-

Energy Efficiency: Mechanical advantage allows operators to achieve high lifting capacities with low input energy. Manual, electric, or motor-driven options are available depending on operational requirements.

-

Cost-Effectiveness: Over the long term, minimal maintenance and extended durability reduce total operational cost, offering a high return on investment compared to other lifting mechanisms.

In essence, worm screw jacks combine precision, safety, and durability, making them a superior choice for industrial and engineering applications where reliability and exact load control are critical.

Detailed Worm Screw Jack Product Parameters

Professional users often require a clear understanding of the technical specifications to determine the most suitable worm screw jack for their application. Below is a consolidated overview of key product parameters:

| Parameter | Specification/Range | Notes |

|---|---|---|

| Load Capacity | 0.5 tons – 50 tons | Depending on worm size and material |

| Lead Screw Type | ACME, Trapezoidal | Precision or heavy-load applications |

| Lift Stroke Length | 50 mm – 5000 mm | Customizable for specific projects |

| Input Torque | 10 Nm – 5000 Nm | Corresponding to manual or motor operation |

| Gear Material | Alloy Steel / Heat-Treated Steel | Enhances strength and reduces wear |

| Housing Material | Cast Iron / Steel / Aluminum | Depends on environmental conditions |

| Self-Locking | Yes | Standard feature for safety |

| Operating Temperature | -20°C to 80°C | Suitable for most industrial environments |

| Drive Options | Manual Handwheel, Electric Motor, Pneumatic | Flexible application modes |

| IP Rating (Motorized Models) | IP55 – IP65 | Provides dust and water resistance |

| Lubrication | Grease-Filled Worm Gear | Reduces friction and maintenance frequency |

| Mounting Options | Base, Flange, Side Mount | Adaptable to installation requirements |

These parameters ensure that engineers and operators can select and configure the optimal worm screw jack for diverse tasks ranging from precise laboratory adjustments to heavy-duty industrial lifts.

Common Questions and Practical Considerations

Q1: How do I choose the correct Worm Screw Jack for my application?

A1: Selection depends on load capacity, stroke length, mounting type, and operational environment. Evaluate whether manual, motor-driven, or electric operation suits your workflow. Check the self-locking feature, IP rating, and torque requirements to ensure safety and performance. Always consider future maintenance and ease of installation.

Q2: Can Worm Screw Jacks handle continuous operation in industrial settings?

A2: Yes. High-quality worm screw jacks with proper lubrication, suitable materials, and adequate motor specification can operate continuously in industrial environments. However, it’s critical to monitor temperature, lubrication levels, and load cycles to prevent premature wear. For extreme loads or high-frequency applications, consulting technical datasheets and manufacturer recommendations is essential.

Finally, for businesses seeking reliable worm screw jack solutions, Hemu offers a range of premium, precision-engineered worm screw jacks suitable for various industrial and mechanical applications. With decades of expertise, Hemu ensures durability, precision, and safety in every unit. To explore our complete range or request a tailored solution, contact us today.