Why Is a Brick Machine Curing Room a Game-Changer for My Factory?

2025-07-30

Before we had a proper brick machine curing room, our production felt like a gamble. Some bricks turned out strong, others cracked during stacking or transport. We blamed the weather, the mix, even the workers. But the real issue was obvious—no consistent curing environment.

Once we added a brick machine curing room, it felt like we moved from trial-and-error to true manufacturing. The results were immediate. No more worrying about whether today’s batch would survive the next day’s loading.

What’s the Real Benefit of Using a Brick Machine Curing Room?

To put it simply: control. The brick machine curing room gives me control over temperature, humidity, and timing. That means the bricks cure evenly, regardless of whether it’s sunny, raining, or humid outside.

In the past, we’d lose bricks on humid days or when curing took too long. That waste added up—both in lost materials and delayed deliveries. With the brick machine curing room, those problems are behind us. The blocks come out with better strength, fewer cracks, and consistent color.

Is It Worth the Investment for Small or Medium Operations?

Absolutely. I used to think a brick machine curing room was something only big companies needed. But after installing one tailored to our plant size, I saw how it changed our daily operations. Curing time dropped, quality rose, and customer complaints nearly disappeared.

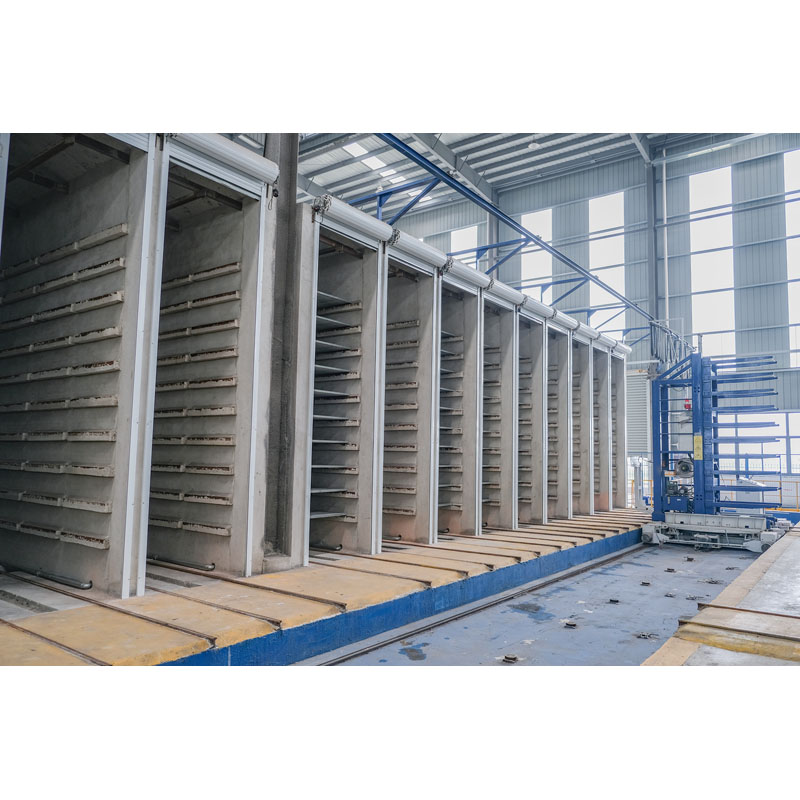

I went with a system from QGM, and their team worked closely with us to design a setup that fit our space. The entire structure was modular and didn’t require major factory changes. That saved us a lot of time and headache.

Does It Help With Production Speed and Planning?

Definitely. Now we can plan daily output with more confidence. Since curing no longer depends on unpredictable outdoor conditions, we stay on schedule. That helps with logistics, delivery planning, and customer satisfaction.

The brick machine curing room also gave us the flexibility to produce different types of bricks in batches without quality differences. Whether it’s hollow blocks or interlocking pavers, everything cures under the same stable settings.

Upgrading to a brick machine curing room was one of the smartest moves I’ve made. It took the guesswork out of brick production and helped us reach a new level of consistency. If you're still curing bricks outdoors or using makeshift methods, this is worth serious consideration.

Our products are highly reliable. If you have any needs, please feel free to contact us at any time. We will be online 24/7 to provide you with efficient solutions.