Why Is the 20L Accumulator Blow Molding Machine the Best Choice for Efficient Plastic Container Production?

2025-10-17

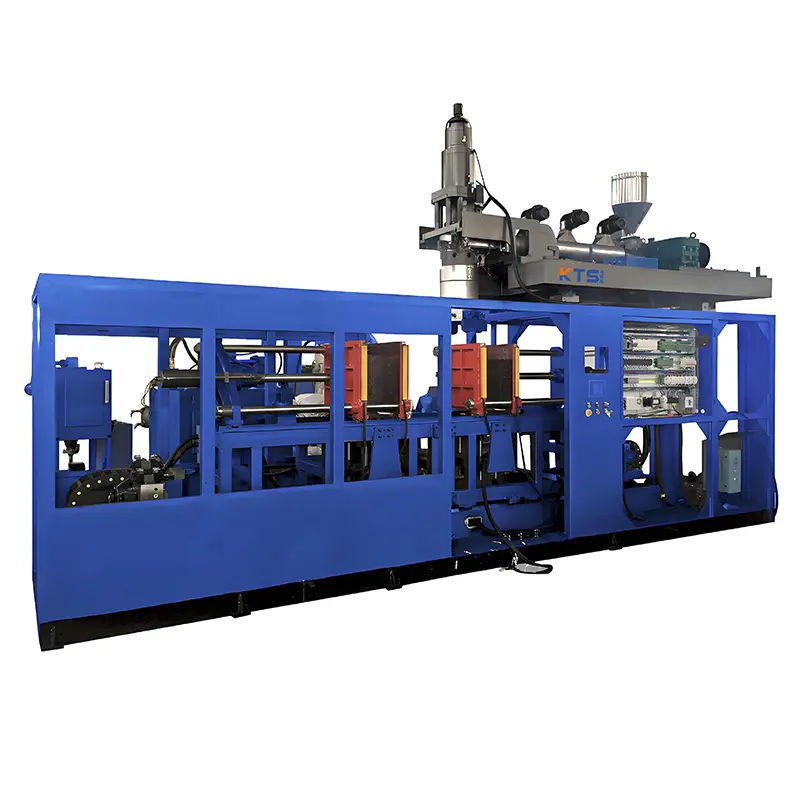

In the competitive world of plastic manufacturing, precision, durability, and efficiency are what define success. The 20L Accumulator Blow Molding Machine has become one of the most sought-after solutions for producing medium to large hollow plastic containers. Designed and manufactured by Ningbo Kaotesi Machinery Manufacturing Co., Ltd., this advanced machine combines intelligent control, high output efficiency, and stable performance — making it an ideal choice for industries that demand reliability and precision.

What Is the 20L Accumulator Blow Molding Machine and How Does It Work?

The 20L Accumulator Blow Molding Machine is a high-performance equipment designed to produce plastic containers, barrels, and industrial packaging ranging from 10L to 30L capacity. It operates on the principle of accumulating molten plastic material in a chamber before being extruded into a parison and blown into a mold cavity. This process ensures even wall thickness, excellent surface finish, and high structural integrity.

Key features include:

-

Accumulator Head Design for smooth material flow.

-

Servo Hydraulic System for energy efficiency.

-

Intelligent PLC Control for precise temperature and pressure adjustments.

-

Heavy-Duty Clamping Unit for consistent molding quality.

Technical Parameters

| Parameter | Specification |

|---|---|

| Model | KTS-20L |

| Material | PE, PP, HDPE |

| Max Container Volume | 20 Liters |

| Clamping Force | 120 kN |

| Accumulator Capacity | 2.5 kg |

| Heating Zones | 6–8 |

| Production Capacity | 120–150 pcs/hour |

| Power Supply | 380V / 50Hz |

| Machine Weight | 8 Tons |

What Is the Role of the 20L Accumulator Blow Molding Machine?

The main role of this machine is to manufacture durable, uniform plastic containers used in industrial packaging, chemical storage, and household applications. It allows manufacturers to produce containers with superior impact resistance and precise wall thickness control, which is essential for liquid and chemical storage industries.

Additionally, it ensures high material utilization and shorter cycle times, helping companies save energy and reduce waste — both key elements for modern, sustainable manufacturing.

How Effective Is the 20L Accumulator Blow Molding Machine in Real Production?

From my experience working with Ningbo Kaotesi Machinery, I have found that this model offers exceptional consistency and reliability. The servo-driven hydraulic system reduces energy consumption by up to 30%, while its optimized die head design ensures uniform material distribution.

The machine also allows for multi-layer extrusion, which improves barrier properties and product aesthetics. As a result, users can expect excellent molding precision, lower maintenance frequency, and longer equipment lifespan.

Why Is It Important to Choose a Reliable Machine Manufacturer?

When investing in a 20L Accumulator Blow Molding Machine, choosing the right manufacturer directly impacts long-term performance and ROI. Ningbo Kaotesi Machinery Manufacturing Co., Ltd. has over 20 years of industry experience, specializing in custom blow molding solutions for various applications. Their machines are exported worldwide and recognized for stable operation, high automation, and durable component quality.

By selecting a trusted manufacturer, I ensure the machine operates with minimal downtime, optimal efficiency, and reliable after-sales support.

Q&A Section

Q1: Why did I choose the 20L Accumulator Blow Molding Machine for my production line?

A1: I needed a machine that could produce 20L plastic barrels with stable wall thickness and reduced cycle times. The 20L Accumulator Blow Molding Machine from Ningbo Kaotesi offered the ideal balance between efficiency and precision.

Q2: How has the 20L Accumulator Blow Molding Machine improved my production efficiency?

A2: It has significantly shortened my production cycles while reducing material waste. The automatic control system ensures every product meets strict quality standards.

Q3: What makes Ningbo Kaotesi's 20L Accumulator Blow Molding Machine different from others on the market?

A3: It's the combination of professional engineering, intelligent PLC control, and energy-saving servo hydraulics that makes it stand out. The machine runs smoothly, requires minimal maintenance, and provides a high return on investment.

Importance and Benefits

The 20L Accumulator Blow Molding Machine is not just an industrial tool—it's a strategic investment in production reliability and long-term growth. It allows manufacturers to:

-

Increase production capacity with stable product quality.

-

Save energy and materials through advanced system design.

-

Customize molds for different product types and sizes.

-

Reduce downtime with smart maintenance features.

Its importance lies in its ability to adapt to various industrial applications — from chemical drums and automotive parts to agricultural containers and household products.

Final Thoughts

In a market that values efficiency and sustainability, the 20L Accumulator Blow Molding Machine by Ningbo Kaotesi Machinery Manufacturing Co., Ltd. represents the perfect fusion of technology and performance. It's designed to help manufacturers achieve better output, higher precision, and lower operational costs.

If you're looking to upgrade your production line or start a new plastic container manufacturing project, don't hesitate to contact us today. Our professional team at Ningbo Kaotesi Machinery Manufacturing Co., Ltd. will provide customized solutions tailored to your specific needs.

Contact us now to learn more about how the 20L Accumulator Blow Molding Machine can revolutionize your production efficiency and product quality!