Why Is the Board Production Line Essential for Modern Manufacturing?

2025-10-30

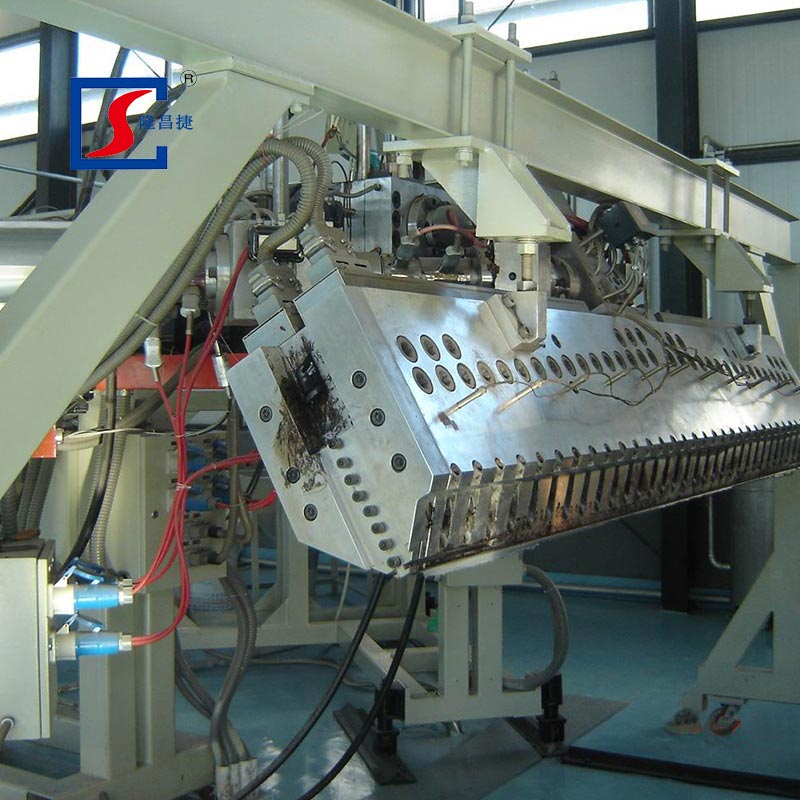

In today's fast-paced manufacturing world, efficiency, precision, and consistency define the success of a production facility. As a professional manufacturer, I have witnessed how the Board Production Line revolutionizes traditional manufacturing processes, offering automation, stability, and high productivity. From raw material feeding to final product packaging, every stage is intelligently designed to ensure quality and reliability. The development of this technology not only improves output but also minimizes waste, energy consumption, and manual labor—making it the backbone of modern panel production industries such as construction materials, furniture, and packaging boards.

The Role and Function of a Board Production Line

A Board Production Line is a complete set of automated equipment used for the continuous production of various types of boards—such as gypsum boards, PVC foam boards, WPC boards, MDF, and particle boards. Its main purpose is to transform raw materials into high-quality finished boards through processes like mixing, extrusion, forming, cutting, cooling, and stacking.

The primary functions include:

-

Material Feeding: Ensures accurate ingredient proportioning.

-

Extrusion or Forming: Shapes materials into uniform board structures.

-

Cutting and Cooling: Guarantees consistent product dimensions and surface finish.

-

Automatic Stacking and Packaging: Reduces labor and boosts efficiency.

Below is a simplified technical parameter table of a typical production line from Qingdao Longchangjie Machinery Co., Ltd.

| Item | Specification | Description |

|---|---|---|

| Production Capacity | 400–1000 kg/h | Adjustable depending on board type |

| Board Width | 600–1220 mm | Suitable for different applications |

| Thickness Range | 3–30 mm | Customizable |

| Line Speed | 0.5–6 m/min | Variable speed control |

| Power Supply | 380V / 50Hz / 3 Phase | Standard industrial voltage |

| Control System | PLC + Touch Screen | Full automation with real-time monitoring |

The Effect and Advantages of Using a Board Production Line

Using a Board Production Line dramatically improves productivity. Compared to manual or semi-automatic systems, it delivers higher precision, consistent product quality, and lower rejection rates. For instance, I once managed a facility where we upgraded from a semi-automatic setup to a fully automated line, and production efficiency increased by 45% within the first three months.

Other notable benefits include:

-

Energy Efficiency: Optimized heating and cooling systems reduce power use.

-

Environmental Protection: Closed-loop dust and waste systems ensure clean operations.

-

Stable Quality: Consistent product specifications through digital control.

-

Reduced Labor Cost: Minimal manual operation required.

These features enable manufacturers to respond faster to market demands while maintaining competitive prices and quality.

The Importance and Long-Term Value of Board Production Lines

The Board Production Line plays a vital role in modern industry, especially as sustainability and automation become global priorities. It allows companies to produce recyclable, lightweight, and durable materials for construction, furniture, and packaging industries.

From an investment standpoint, the line's durability and low maintenance cost ensure long-term profitability. Furthermore, its flexibility to adapt to various materials (such as PVC, WPC, or MDF) makes it suitable for diversified product portfolios. As I often tell new clients, investing in a reliable production line from Qingdao Longchangjie Machinery Co., Ltd. is not just buying a machine—it's a long-term strategy for business growth and innovation.

Q&A: Understanding the Board Production Line

Q1: What makes the Board Production Line different from traditional manual board-making systems?

A1: Traditional systems rely heavily on human operation, leading to inconsistent quality. The Board Production Line, however, integrates automatic control systems, ensuring stable production, uniform thickness, and smooth surfaces across all boards.

Q2: How can I choose the right Board Production Line for my factory?

A2: The key is to match your production capacity, board type, and budget. At Qingdao Longchangjie Machinery Co., Ltd., we provide customized solutions tailored to your specific requirements—whether it's for PVC foam boards or WPC decking panels.

Q3: Is maintenance complicated for the Board Production Line?

A3: Not at all. Regular cleaning, lubrication, and timely part replacement are sufficient. Our team offers complete after-sales training to ensure operators handle the system confidently and efficiently.

Why Choose Qingdao Longchangjie Machinery Co., Ltd.?

With decades of experience in manufacturing and exporting machinery, Qingdao Longchangjie Machinery Co., Ltd. has earned a solid reputation for innovation, reliability, and professional service. We specialize in designing advanced Board Production Lines that meet international standards while offering cost-effective performance. Our products are widely used across Asia, Europe, and the Middle East, receiving excellent feedback from clients for their precision and durability.

We believe that every business deserves a production line that combines technology, efficiency, and sustainability. Let us help you build the future of intelligent manufacturing.

If you are interested in our Board Production Line or need customized solutions, please contact us today — our professional team is ready to assist you with detailed product information, technical support, and turnkey installation service.