Why Is the FL Mechanical Bar Screen the Best Solution for Modern Wastewater Treatment Systems?

2025-10-22

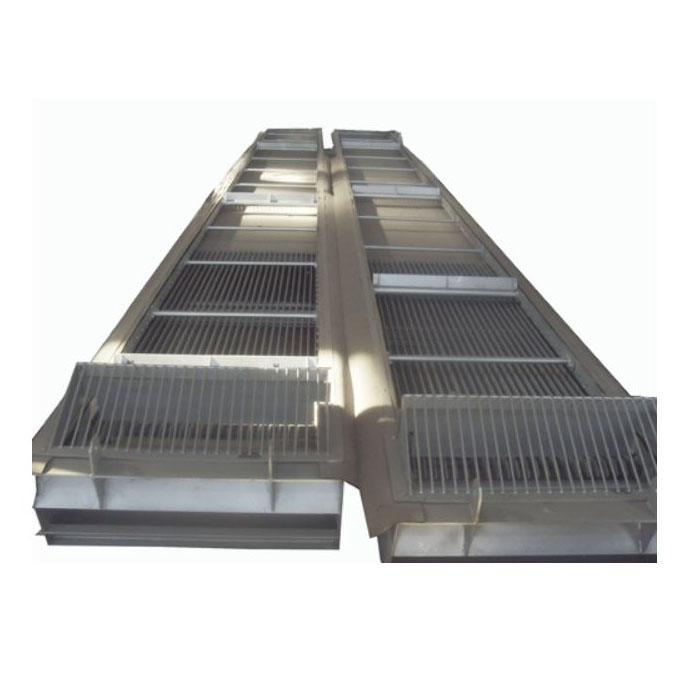

In today's fast-developing industrial and municipal wastewater treatment sector, the FL Mechanical Bar Screen has become one of the most indispensable pieces of equipment. Designed and manufactured by Tianjin FYL Technology Co., Ltd., this advanced screening system efficiently removes large solid particles, rags, and debris from sewage, protecting downstream equipment from damage and improving the overall operational efficiency of wastewater plants. I have personally seen how this system transforms the filtration process into a cleaner, safer, and more automated operation.

Understanding the FL Mechanical Bar Screen

The FL Mechanical Bar Screen is an automatic device used at the front end of wastewater treatment plants. It operates continuously to intercept and remove floating or suspended solids, such as plastics, branches, rags, and other debris. The entire system consists of a sturdy frame, transmission chain, rake teeth, and a self-cleaning mechanism, all of which ensure efficient operation with minimal maintenance.

Below is a simplified technical parameter table for the FL series:

| Model | Channel Width (mm) | Bar Spacing (mm) | Motor Power (kW) | Handling Capacity (m³/h) |

|---|---|---|---|---|

| FL-600 | 600 | 5–25 | 0.75 | 100–300 |

| FL-800 | 800 | 5–25 | 1.1 | 200–500 |

| FL-1000 | 1000 | 5–25 | 1.5 | 300–800 |

| FL-1200 | 1200 | 5–25 | 2.2 | 400–1000 |

What Is the Role of the FL Mechanical Bar Screen?

The FL Mechanical Bar Screen serves as the first line of defense in a wastewater treatment process. Its main role is to intercept large debris before the wastewater enters sedimentation tanks or biological treatment zones. By removing solid contaminants early, it prevents blockage, reduces equipment wear, and ensures a stable flow rate.

I have observed that facilities equipped with FL screens experience fewer shutdowns and lower maintenance costs. Moreover, its automatic raking system ensures continuous operation without the need for manual cleaning, significantly improving workplace safety and efficiency.

How Effective Is the FL Mechanical Bar Screen in Real Applications?

From a performance standpoint, the FL Mechanical Bar Screen offers outstanding results. The high-strength stainless-steel bars ensure long service life, while the fully enclosed drive system minimizes noise and odor leakage.

Key performance highlights include:

-

Continuous Operation: 24-hour automatic running without manual intervention.

-

High Efficiency: Up to 95% removal of large solid waste before secondary treatment.

-

Durability: Corrosion-resistant materials suitable for harsh wastewater environments.

-

Low Maintenance: Self-cleaning design and easy part replacement.

In my experience, after installing the FL Mechanical Bar Screen, treatment plants notice a 20–30% improvement in efficiency and a significant reduction in manual labor costs.

Why Is the FL Mechanical Bar Screen So Important for Wastewater Plants?

The importance of this screen lies in its ability to protect downstream pumps, aeration systems, and biological reactors. Without an effective screening stage, solid waste can cause severe equipment damage, leading to costly repairs and downtime.

The FL Mechanical Bar Screen not only ensures smooth operation but also aligns with modern environmental standards by improving the overall quality of discharged water. It represents the perfect combination of mechanical strength, automation, and environmental responsibility.

FL Mechanical Bar Screen – FAQ Section

Q1: What makes the FL Mechanical Bar Screen different from traditional bar screens?

A1: The FL series features a fully automatic chain-driven system that allows for continuous, unattended operation. Its modular design makes maintenance simpler, while the precision-engineered rake teeth ensure complete debris removal without clogging.

Q2: Can the FL Mechanical Bar Screen be customized for different treatment capacities?

A2: Yes. Tianjin FYL Technology Co., Ltd. provides customized design solutions to fit various channel widths, flow rates, and debris load levels, ensuring perfect compatibility with each client's wastewater treatment system.

Q3: How does the FL Mechanical Bar Screen improve operational efficiency?

A3: By continuously intercepting solids and automatically cleaning itself, the FL Mechanical Bar Screen prevents downstream blockages, reduces pump maintenance frequency, and extends the lifespan of entire wastewater systems. I've personally seen facilities save both energy and maintenance time after upgrading to this system.

Conclusion

The FL Mechanical Bar Screen from Tianjin FYL Technology Co., Ltd. stands out as an intelligent, durable, and high-efficiency solution for modern wastewater treatment plants. Whether applied in municipal sewage systems or industrial facilities, it delivers consistent performance, reduced maintenance costs, and improved water treatment quality.

If you are looking for a reliable and efficient mechanical screening solution for your facility, contact us today to learn more about how the FL Mechanical Bar Screen can transform your wastewater management process and ensure long-term operational success.