Why Is the Photovoltaic Welding Strip Rolling Mill Essential for Modern Solar Panel Production?

2025-11-10

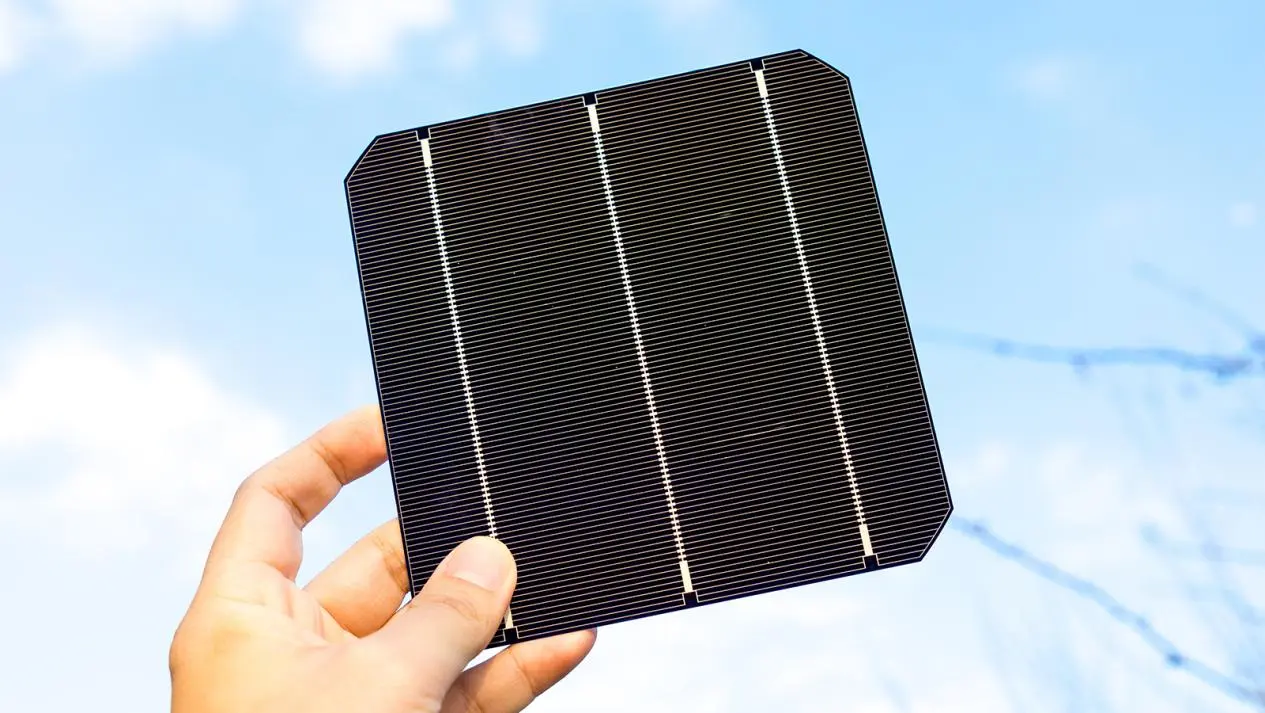

As global demand for renewable energy continues to rise, the efficiency and quality of photovoltaic (PV) module manufacturing have become more important than ever. Among the key components of this production process is the Photovoltaic Welding Strip Rolling Mill, a piece of precision equipment that ensures high-quality metal strips used in solar cell welding. At Jiangsu Youzha Machinery Co., Ltd., we specialize in providing advanced rolling mill solutions designed to improve accuracy, stability, and production efficiency for the photovoltaic industry.

What Is a Photovoltaic Welding Strip Rolling Mill?

A Photovoltaic Welding Strip Rolling Mill is a precision machine used to roll and shape copper or tinned copper strips that serve as interconnect ribbons in photovoltaic modules. These ribbons are crucial because they connect solar cells within a module, allowing current to flow efficiently between them.

The rolling mill's role is to ensure uniform thickness, smooth surface quality, and superior conductivity of these strips. By maintaining consistent dimensions and tension, it guarantees optimal welding performance during the solar panel assembly process.

Technical Parameters of Our Rolling Mill

Below is an overview of the typical parameters of the Photovoltaic Welding Strip Rolling Mill produced by Jiangsu Youzha Machinery Co., Ltd.:

| Parameter | Specification |

|---|---|

| Strip Material | Copper, Tinned Copper |

| Strip Width Range | 1.5 – 10 mm |

| Strip Thickness Range | 0.05 – 0.3 mm |

| Rolling Speed | 0–100 m/min |

| Main Motor Power | 11–30 kW |

| Rolling Accuracy | ±0.001 mm |

| Control System | PLC + Touch Screen |

| Cooling & Lubrication System | Integrated, Adjustable Flow |

| Application | PV Ribbon and Busbar Rolling |

This high-performance machine ensures consistent rolling results, reduced material waste, and increased line efficiency.

Function and Working Effect

The primary function of the Photovoltaic Welding Strip Rolling Mill is to reduce the thickness of copper or tinned copper strips while improving surface smoothness and mechanical strength. The working effect includes:

-

High precision: Ensures exact strip dimensions for stable current conduction.

-

Enhanced surface quality: Reduces micro-defects for reliable welding.

-

Stable tension control: Prevents strip deformation and material loss.

-

Improved production efficiency: Continuous operation ensures a steady output for mass production.

Why Is It So Important in the Photovoltaic Industry?

In the manufacturing of solar panels, every micron counts. A deviation in ribbon thickness or flatness can lead to welding failures or efficiency losses. The Photovoltaic Welding Strip Rolling Mill directly impacts the electrical conductivity, durability, and overall performance of PV modules.

From my experience working at Jiangsu Youzha Machinery Co., Ltd., I've seen how our precision rolling mills help clients reduce their defect rates and improve output quality. This is why investing in a high-quality machine is not an expense—it's a strategic decision for long-term competitiveness.

Q&A: Understanding the Photovoltaic Welding Strip Rolling Mill

Q1: What makes your Photovoltaic Welding Strip Rolling Mill different from others on the market?

A1: Our rolling mill integrates advanced PLC control, ensuring real-time monitoring of rolling pressure, temperature, and speed. This intelligent system allows for consistent rolling quality and quick adjustments, providing a competitive advantage for high-volume solar ribbon production.

Q2: How does the rolling mill improve welding performance in solar panels?

A2: By achieving precise strip thickness and smooth surface texture, the Photovoltaic Welding Strip Rolling Mill enhances solderability, reducing welding defects such as poor adhesion or uneven solder flow. This directly increases module efficiency and lifespan.

Q3: Why should I choose Jiangsu Youzha Machinery Co., Ltd. for my equipment supplier?

A3: At Jiangsu Youzha Machinery Co., Ltd., we not only supply machinery but also offer technical consultation, customized solutions, and after-sales support. I personally ensure that each client receives tailored service to match their production goals and material requirements.

The Significance and Advantages of Our Equipment

Our Photovoltaic Welding Strip Rolling Mill is designed to meet the growing demands of high-speed, high-precision PV production lines. Its significance lies in:

-

Ensuring product consistency: Uniform strips improve module electrical performance.

-

Reducing energy loss: Precision rolling minimizes resistance across the panel.

-

Enhancing production reliability: Durable design supports long-term continuous operation.

-

Lowering maintenance costs: Advanced lubrication and cooling systems extend service life.

Main Features Summary

-

Compact design with low vibration structure

-

Energy-efficient operation with servo-driven system

-

Easy integration into automated production lines

-

Customizable for different strip sizes and materials

-

Real-time quality control system with data tracking

Conclusion

In the era of green energy, the Photovoltaic Welding Strip Rolling Mill plays a vital role in ensuring the reliability and efficiency of solar panel production. At Jiangsu Youzha Machinery Co., Ltd., we are dedicated to helping our clients achieve higher output, better quality, and more sustainable manufacturing through cutting-edge technology and professional service.

If you are looking to upgrade your PV manufacturing equipment or seek a custom rolling solution, contact us today to learn how our products can power your business success.