Why Is the RDF Shredder the Future of Waste-to-Energy Processing?

2025-11-04

In today’s global push toward sustainability and circular economy practices, Refuse-Derived Fuel (RDF) has emerged as one of the most efficient and environmentally responsible energy alternatives. At the heart of RDF production lies one key technology — the RDF Shredder.

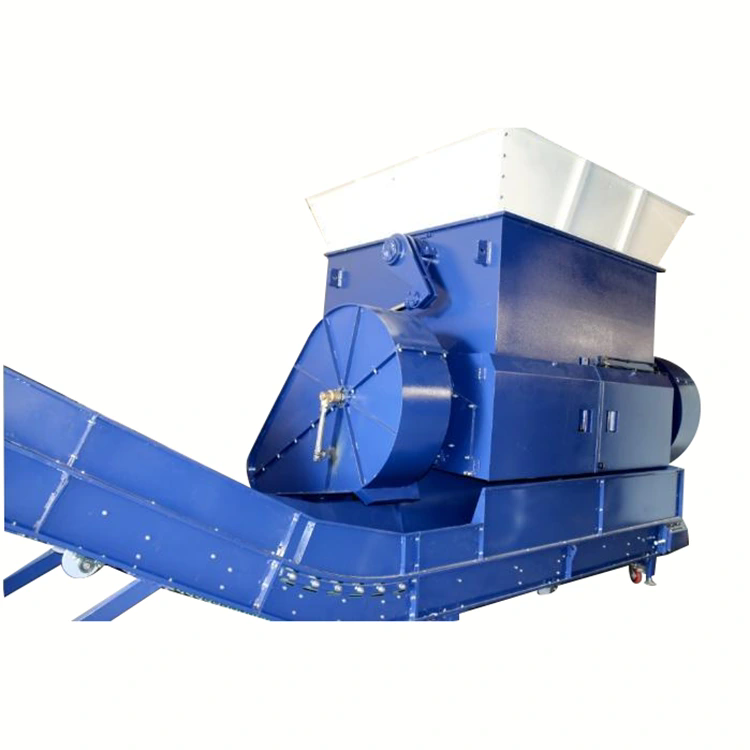

An RDF Shredder is a high-performance industrial shredding machine designed to process mixed solid waste into a uniform particle size suitable for use as alternative fuel in cement kilns, power plants, and waste-to-energy facilities. By converting waste into valuable fuel, RDF shredders not only reduce landfill volume but also contribute to carbon emission reduction and energy recovery.

The growing demand for cleaner and renewable fuel sources has made RDF shredders indispensable in municipal waste treatment, recycling centers, and industrial waste management facilities. Their robust design, high torque, and energy-efficient motors ensure long-term reliability even when handling complex and variable waste streams such as plastics, paper, textiles, rubber, and wood.

Why Is the RDF Shredder Considered a Game-Changer in Waste-to-Energy Systems?

The RDF Shredder represents a technological leap that bridges waste management and sustainable energy generation. Unlike conventional waste processing systems, RDF shredders are optimized for high throughput, homogenous output, and energy efficiency — three factors critical to large-scale fuel production.

Key Advantages of RDF Shredder Technology

| Feature | Description | Benefit |

|---|---|---|

| High Torque & Low Speed Drive | Utilizes powerful dual-shaft or single-shaft drive systems with low-speed operation | Reduces wear and ensures consistent shredding for mixed waste materials |

| Intelligent Control System | Equipped with automated PLC controls and smart overload protection | Enhances safety and minimizes downtime |

| Adjustable Output Size | Customizable screen size options ranging from 30–80 mm | Tailors RDF output to specific combustion or gasification requirements |

| Heavy-Duty Cutting Blades | Made from wear-resistant alloy steel with precision-engineered geometry | Extends service life and improves cutting efficiency |

| Optimized Energy Consumption | High-efficiency electric motors with low operational cost | Ensures economic and environmental sustainability |

| Easy Maintenance Access | Modular construction with quick-release panels | Reduces maintenance time and improves operational uptime |

| Dust and Noise Control System | Integrated dust collection and noise suppression features | Provides a safer, cleaner working environment |

This advanced combination of durability, energy efficiency, and intelligent automation makes the RDF shredder an essential solution for modern waste processing operations. It not only handles heterogeneous waste but also ensures consistent RDF quality, which is crucial for stable energy generation and emissions control.

How Does an RDF Shredder Work? Understanding the Process Behind the Technology

To fully appreciate the efficiency of RDF shredders, it’s important to understand their working principles. The RDF shredding process involves several carefully engineered stages to ensure maximum energy recovery from waste materials.

Step-by-Step RDF Shredding Process

-

Waste Feeding and Sorting: Mixed solid waste is fed into the shredder via conveyors. Pre-sorting equipment may remove metals or oversized debris.

-

Primary Shredding: Large waste pieces are reduced into medium-sized fragments by heavy-duty rotating blades.

-

Magnetic Separation: Ferrous materials are extracted to prevent damage to downstream equipment.

-

Secondary Shredding: Waste passes through a finer shredding stage, where it is processed into uniform particles.

-

Screening and Refinement: Screens and air classifiers ensure consistent particle size and remove unwanted materials.

-

RDF Output Collection: The processed material is conveyed to storage or directly fed into fuel preparation systems.

This systematic process transforms municipal or industrial waste into a homogeneous, high-calorific fuel suitable for co-firing with coal or use in dedicated RDF combustion facilities.

Technical Specifications (Example Model)

| Model | Power (kW) | Rotor Speed (rpm) | Capacity (t/h) | Output Size (mm) | Weight (kg) |

|---|---|---|---|---|---|

| RDF-75 | 75 | 60 | 5–8 | 50–80 | 8,500 |

| RDF-110 | 110 | 70 | 8–12 | 40–70 | 12,000 |

| RDF-160 | 160 | 75 | 12–18 | 30–60 | 16,500 |

| RDF-250 | 250 | 80 | 18–25 | 30–50 | 22,000 |

These parameters illustrate how RDF shredders can be tailored for specific operational needs, whether for municipal solid waste, industrial offcuts, or mixed recyclables.

What Are the Key Applications and Future Trends of RDF Shredders?

Current Applications

-

Cement Industry: As an alternative fuel source for rotary kilns, RDF reduces fossil fuel consumption and CO₂ emissions.

-

Power Plants: Used in co-firing systems to improve combustion efficiency and energy yield.

-

Municipal Waste Treatment: Integral to waste-to-energy facilities for converting urban waste into fuel.

-

Recycling Facilities: Helps prepare waste streams for further processing or recovery.

-

Industrial Waste Management: Handles production scraps, packaging waste, and non-recyclable plastics efficiently.

Emerging Trends in RDF Shredder Technology

-

Automation and AI Integration: Advanced control systems now use predictive analytics to adjust torque, detect overloads, and optimize blade rotation in real-time.

-

Enhanced Energy Recovery: Future RDF systems will integrate with biomass and gasification units for hybrid energy generation.

-

Sustainability and Carbon Tracking: Smart monitoring tools are being adopted to measure carbon footprint reduction during RDF production.

-

Compact Modular Designs: Newer RDF shredders feature space-saving designs suitable for on-site installation in urban facilities.

-

Digital Twin Maintenance Systems: Real-time diagnostics will soon predict maintenance schedules to prevent downtime.

These innovations signal that RDF shredders are evolving into smart, interconnected components of a circular economy — transforming waste into a valuable energy resource while supporting global carbon neutrality goals.

Common Questions About RDF Shredders

Q1: What types of waste can be processed by an RDF Shredder?

A: RDF shredders are designed to handle a wide range of materials, including mixed municipal solid waste (MSW), industrial waste, plastic films, paper, textiles, rubber, and light metal components. The robust cutting mechanism ensures efficient shredding without frequent maintenance, making it suitable for both pre- and post-consumer waste streams.

Q2: How does an RDF Shredder improve the efficiency of waste-to-energy facilities?

A: By producing uniform particle sizes with high calorific value, RDF shredders ensure more stable combustion in energy recovery systems. The consistency of shredded material enhances fuel efficiency, reduces residue, and optimizes air-fuel ratio control, which ultimately leads to higher energy yield and lower emissions.

Why the RDF Shredder Represents the Future of Sustainable Energy — and Why 3E Machinery Leads the Way

The future of waste management is not about disposal — it is about transformation. RDF shredders play a critical role in turning waste into a renewable energy source, helping industries reduce landfill dependency, cut greenhouse gas emissions, and achieve sustainability goals.

Among global leaders in waste processing solutions, 3E Machinery has built a reputation for manufacturing high-performance RDF shredders with unmatched reliability, precision, and energy efficiency. With years of engineering expertise and an unwavering commitment to environmental innovation, 3E Machinery offers comprehensive waste-to-energy equipment that supports large-scale and industrial operations worldwide.

Every RDF shredder from 3E Machinery is engineered to meet international quality standards, combining intelligent control technology, advanced safety systems, and customizable configurations to match specific operational demands.

To learn more about how 3E Machinery’s RDF shredders can enhance your waste-to-energy processes, contact us today for detailed product consultation and tailored equipment solutions.