Why Is the ZN 1500-2 Single Pallet Big Board Machine the Ideal Choice for Modern Concrete Production?

2025-11-10

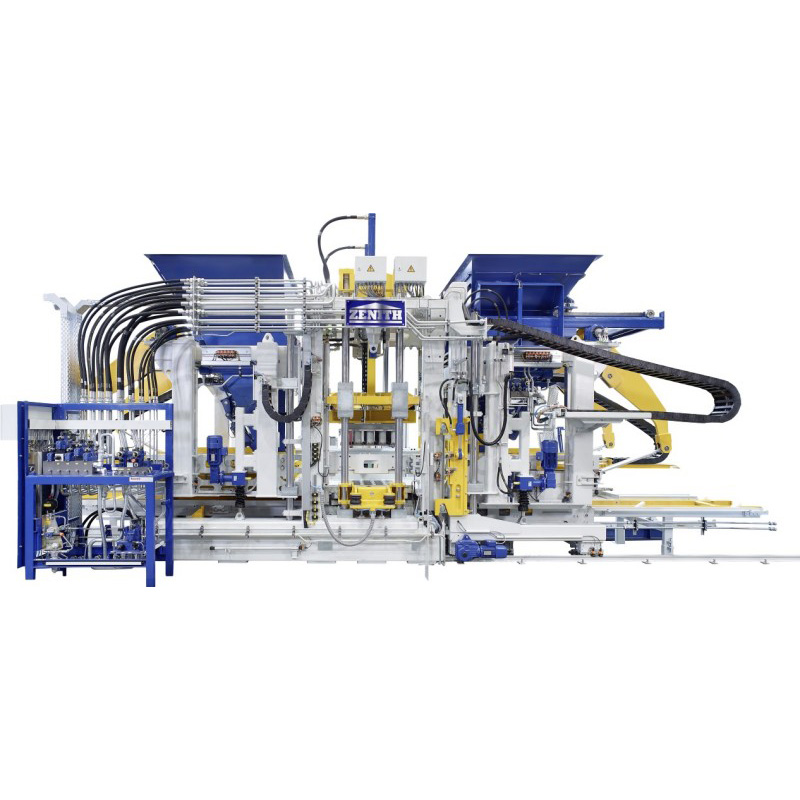

In the field of concrete block manufacturing, automation and precision are the cornerstones of efficiency. At ZENITH Maschinenfabrik GmbH, we take pride in offering advanced equipment designed to meet the diverse needs of global construction materials producers. Among our flagship products, the ZN 1500-2 Single Pallet Big Board Machine stands out for its robust design, intelligent control, and exceptional productivity. As I've worked with this machine firsthand, I can confidently say that it represents a major leap forward in block-making technology—bridging the gap between high efficiency, flexibility, and long-term reliability.

What Makes the ZN 1500-2 Single Pallet Big Board Machine Special?

The ZN 1500-2 Single Pallet Big Board Machine is a fully automated system for producing high-quality concrete blocks, pavers, curbstones, and other precast elements. Built on decades of German engineering expertise, it integrates servo vibration technology and intelligent hydraulic systems to achieve superior compaction uniformity and speed. Its modular design also allows users to easily upgrade production capabilities as business scales.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Production System | Single Pallet Big Board Technology |

| Pallet Size | 1400 x 1300 mm |

| Cycle Time | Approx. 12–15 seconds (depending on product type) |

| Compaction System | Servo Vibration + Hydraulic Pressure |

| Control System | Siemens PLC with touch-screen interface |

| Average Output | Up to 15,000 blocks per 8-hour shift |

| Power Consumption | Energy-saving servo drives |

| Automation Level | Fully automatic with remote monitoring |

How Does It Work and What Are the Benefits?

The working process of the ZN 1500-2 Single Pallet Big Board Machine begins with precise material dosing and mixing, followed by vibration compaction under optimized hydraulic pressure. Each cycle is engineered to maximize density and surface smoothness, ensuring every block meets strict quality standards.

Main Advantages:

-

High Production Capacity – Continuous operation with minimal downtime.

-

Energy Efficiency – Servo-driven vibration reduces power consumption by up to 30%.

-

Precision Engineering – Uniform block density and consistent quality output.

-

Ease of Operation – User-friendly control system for simplified adjustments.

-

Longevity – Designed for durability with wear-resistant components.

As an operator, I've found that the intuitive design and automated control system reduce manual intervention dramatically, allowing me to focus on quality management and workflow optimization instead of machine troubleshooting.

What Results Can Users Expect?

The use of servo vibration technology ensures exact compaction energy distribution, reducing waste and improving block consistency. The ZN 1500-2 Single Pallet Big Board Machine achieves impressive results even with challenging raw materials, offering flexibility in product design and size.

Performance Outcomes:

-

Improved productivity by up to 25% compared with conventional models.

-

Reduced operational costs due to lower energy and maintenance requirements.

-

Enhanced surface finish for high-end architectural applications.

From my experience, these results are not just numbers—they translate directly into increased profitability and competitiveness for block manufacturers.

Why Is This Machine Important for Modern Construction?

Today's construction industry demands sustainable, cost-effective, and scalable solutions. The ZN 1500-2 Single Pallet Big Board Machine fulfills all three. By combining high precision with low energy consumption, it aligns perfectly with the industry's push toward environmentally conscious manufacturing. Its modular system also allows for seamless integration into existing production lines, supporting long-term growth and innovation.

Q&A: Common Questions About the ZN 1500-2 Single Pallet Big Board Machine

Q1: What kind of products can the ZN 1500-2 produce?

A1: It can manufacture concrete blocks, hollow bricks, paving stones, curbstones, and other special shapes with exceptional dimensional accuracy.

Q2: How does the single pallet system improve efficiency?

A2: The single pallet concept minimizes idle time by allowing continuous feeding and compaction cycles without interruption, thus enhancing throughput.

Q3: Is maintenance complicated for such a high-tech system?

A3: Not at all. The machine is designed with accessibility in mind, featuring centralized lubrication points and an intelligent diagnostic system for easy preventive maintenance.

Q4: Can the system be customized for different product designs?

A4: Yes. Molds can be changed quickly and safely, giving manufacturers flexibility to adapt to market demands.

Q5: How does it contribute to sustainable production?

A5: The servo drive system and energy-optimized hydraulics reduce overall power usage, helping companies achieve eco-friendly manufacturing goals.

Final Thoughts

The ZN 1500-2 Single Pallet Big Board Machine from ZENITH Maschinenfabrik GmbH is more than just a production tool—it's a strategic investment in modern, automated concrete manufacturing. Its innovative design, precision performance, and energy efficiency make it the perfect choice for producers aiming to scale sustainably and maintain top-tier quality in every product batch.

If you're looking to elevate your concrete production process and stay ahead of your competitors, contact us today to learn how the ZN 1500-2 Single Pallet Big Board Machine can transform your manufacturing line.