Why should you choose a Block Making Machine from Quangong Machinery co., Ltd?

2025-08-14

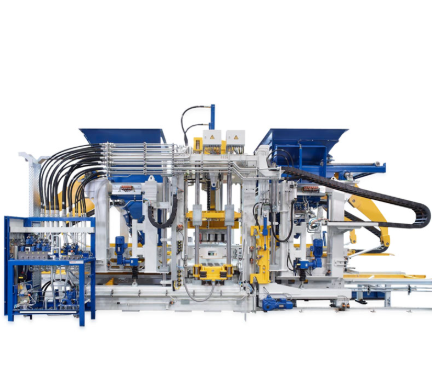

A well-chosen Block Making Machine is the backbone of any efficient masonry or concrete product operation. Whether you're launching a small production yard or scaling an industrial plant, the right equipment improves productivity, lowers costs, and raises finished-product consistency — all of which boost your competitive edge online and offline. This article, written from two decades of SEO and industry experience, explains how a high-quality Block Making Machine delivers value, lists clear technical parameters, shows where and how it's used, and answers the most common buyer questions in a concise Q&A format.

what a Block Making Machine does and who benefits

A Block Making Machine mixes, molds, compresses, and cures concrete or cementitious raw materials into standardized paving blocks, hollow blocks, solid bricks, interlocking blocks, and other precast elements. Modern machines combine automated material dosing, vibration/compaction systems, and quick mold changes to produce large volumes with consistent density and dimensional accuracy.

Key selling points for buyers:

-

Repeatable quality and reduced rejects.

-

Faster cycle times (more blocks per hour).

-

Flexibility of molds and products without heavy retooling.

-

Lower long-term operating cost vs. manual casting.

Technical specifications & parameters

Below are standard technical parameters that buyers should expect from a high-performance Block Making Machine. These numbers are representative; exact figures should be confirmed per model.

Quick highlights :

-

Production capacity: 1,000–12,000 blocks per 8-hour shift (model dependent).

-

Power supply: 3-phase, 380–415 V (or local equivalent).

-

Control system: PLC with HMI touch screen for recipe/mold management.

Simple parameter table

| Parameter | Typical Specification |

|---|---|

| Production capacity (blocks/hour) | 80 – 1,500 (depending on product & model) |

| Power consumption | 5 – 60 kW (model dependent) |

| Cycle time | 8 – 30 seconds |

| Max mold size | up to 1200 × 800 mm (custom available) |

| Machine weight | 2,000 – 18,000 kg |

| Control | PLC + HMI |

| Compaction system | Hydraulic press + vibration |

| Material feeding | Hopper / Conveyor / Automatic batching |

Typical applications

-

Urban paving and landscaping pavers.

-

Hollow blocks for residential and commercial walls.

-

Solid bricks for load-bearing structures.

-

Special profiles (curbstones, floor tiles, decorative blocks).

Installation & footprint

-

Foundation: many hydraulic machines require a reinforced concrete foundation; compact models often run on plain floors.

-

Utilities: confirm available three-phase power and compressed air if required.

-

Logistics: plan for mold storage and curing area (rack or pallet curing).

Block Making Machine — Frequently Asked Questions (FAQ)

Q: What production capacity can I expect from a Block Making Machine?

A: Capacity depends on the model and product type; compact machines typically produce a few hundred blocks per hour while automated lines can reach over 1,000–1,500 units per hour — calculate based on cycle time, number of molds, and shift length.

Q: How does the Block Making Machine ensure consistent block quality?

A: Quality is achieved by precise material batching, controlled vibration/compaction, and repeatable PLC recipes; consistent curing and temperature control also play a critical role in final strength.

Q: What raw materials are compatible with a Block Making Machine?

A: Machines accept a range of mixes: cement, sand, crushed stone, fly ash, slag, and additives. The exact mix design depends on the product's required strength and finish.

Final notes

Choosing the right Block Making Machine is a strategic step that affects product quality, margin, and long-term operational resilience. Prioritize vendors who provide transparent technical specifications, local parts and service, and clear commissioning and training plans.

For procurement, technical inquiries, or to request model datasheets and pricing, please contact: Quangong Machinery co., Ltd

If you'd like, we can prepare a tailored recommendation comparing three models based on your exact product mix, required capacity, and available floor space — including estimated ROI and a simple cost comparison table.