Why Should You Choose a CNC Drilling Tapping Machine for Your Manufacturing Needs?

2025-08-15

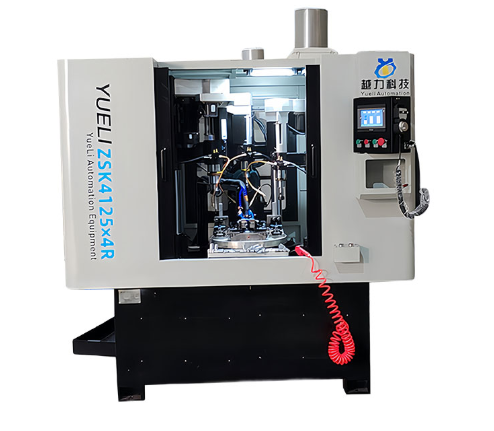

In the fast-paced world of manufacturing, precision, speed, and efficiency are the cornerstones of success. A CNC Drilling Tapping Machine is a critical tool that combines automated drilling and tapping into one streamlined process, helping companies save time, reduce labor costs, and improve product quality. Whether you are producing automotive components, electronics housings, or metal parts for industrial machinery, this equipment ensures that every hole is accurately drilled and every thread is perfectly tapped—every time.

In this article, we will explore the functions, technical specifications, benefits, and applications of a CNC Drilling Tapping Machine, and answer the most common questions that customers ask before investing in this equipment.

Understanding the CNC Drilling Tapping Machine

A CNC Drilling Tapping Machine is a computer-controlled piece of equipment designed to automate two essential machining processes: drilling holes into a workpiece and tapping threads within those holes. Unlike manual operations, CNC technology ensures repeatable precision, eliminating the risk of operator error and achieving higher production consistency.

Key points to understand:

-

Automation: The machine operates based on pre-programmed tool paths.

-

Versatility: Can handle metals, plastics, and composite materials.

-

Productivity: Drilling and tapping are done in one continuous process.

-

Accuracy: Hole position and thread pitch are highly precise.

These machines are widely used in industries such as:

-

Automotive and aerospace

-

Electrical enclosures manufacturing

-

Heavy machinery parts production

-

Consumer electronics

Technical Parameters and Specifications

When selecting a CNC Drilling Tapping Machine, understanding its technical parameters is crucial. Below is an overview of the key specifications:

Key Features List:

-

High-speed spindle for fast drilling and tapping cycles

-

Servo motor drive for precise positioning

-

User-friendly CNC controller interface

-

Rigid cast-iron structure for stability

-

Multi-axis capability (X, Y, Z) for complex part geometry

-

Automatic lubrication system to reduce wear

Specification Table:

| Parameter | Specification |

|---|---|

| Spindle Speed Range | 200 – 6000 RPM |

| Drilling Capacity | Max 20 mm |

| Tapping Capacity | M3 – M16 |

| Table Size | 800 x 500 mm |

| Travel (X/Y/Z) | 500 / 400 / 300 mm |

| Positioning Accuracy | ±0.005 mm |

| Control System | CNC Controller with LCD Interface |

| Power Supply | AC 380V, 50/60 Hz |

The right choice depends on your workpiece size, material type, and production volume.

Advantages of Using a CNC Drilling Tapping Machine

The decision to invest in this type of machinery should be based on tangible production benefits:

a) Higher Efficiency

The integration of drilling and tapping in a single setup eliminates multiple clamping and alignment steps, significantly reducing cycle time.

b) Consistent Quality

CNC precision ensures that every hole and thread meets the exact design requirements, reducing defects and rework.

c) Labor Savings

One operator can manage multiple machines at once, lowering labor costs.

d) Versatile Application

The machine can be adapted for small batch production or high-volume runs, making it suitable for various industries.

e) Better Tool Life

Stable cutting conditions and controlled feed rates reduce wear on tools, lowering maintenance costs.

CNC Drilling Tapping Machine – FAQ

Q1: What materials can a CNC Drilling Tapping Machine work with?

A1: It can process a wide range of materials including mild steel, stainless steel, aluminum, brass, and engineering plastics. By adjusting spindle speed, feed rate, and tool selection, the machine can handle both soft and hard materials with excellent precision.

Q2: How does it improve production speed compared to traditional methods?

A2: Traditional drilling and tapping require two separate setups, each involving repositioning of the workpiece. The CNC Drilling Tapping Machine combines these steps into one, controlled by a pre-programmed CNC program, reducing setup time and machining cycles by up to 50%.

Q3: Is it suitable for both small and large batch production?

A3: Yes, CNC Drilling Tapping Machines are designed for flexibility. For small batches, it reduces manual labor and increases consistency; for large batches, it ensures high-speed automated production without sacrificing accuracy.

Final Thoughts

Choosing the right CNC Drilling Tapping Machine can transform your production line by increasing output, reducing waste, and ensuring perfect thread quality every time. With precise control, durability, and automation, it is a long-term investment that delivers measurable results.

For more details on how to integrate this machine into your production process, contact Yueli Automation Equipment Co., Ltd today and discover how we can optimize your manufacturing capabilities.